Jul 14 2008

The GKN Aerospace team in the Company's Composites Research Centre is in the final stages of work on the three year Integrated Wing, Advanced Technology Verification Programme (IW-ATVP) which is trialling multiple new manufacturing processes for composite aircraft wing ribs, skins and spars.

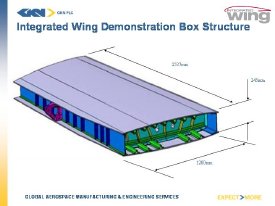

Integrated wing demonstration box structure.

Integrated wing demonstration box structure.

Frank Bamford, Vice President Business Development, of GKN Aerospace comments: "The Integrated Wing programme is a key element in a matrix of research and development activities through which our team is developing new manufacturing methodologies designed specifically for composite assemblies rather than adapting traditional processes developed for metallic structures - as has largely been the case across the industry to date."

By the end of 2008, using innovative processes such as automated tape laying, hot drape forming, microwave curing, self heated tooling, composite fastening and melding, the Company will have produced a full 'closed cell box' demonstrator. Closed cell box sections are found in assemblies such as wings, vertical and horizontal stabilisers, flaps, ailerons, elevators and rudders and form a major part of the aircraft structure, often making up some 30 % of the airframe weight.

Automated Tape Laying (ATL) of carbon fibre tape is already producing an over 75% reduction in man hours compared to manual methods. Hot drape forming will convert the flat stack of composite material to a complex formed component. Out of autoclave curing aims to eliminate the size limitations, and manufacturing bottleneck, inherent in using an autoclave to cure the final item. Microwave curing offers an environmentally friendly alternative to autoclaves by using much less power and potentially opens up new joining methods. And composite fasteners are being tested to compare with traditional metal items for weight, lightning strike compatibility and cost.

As part of the range of research and development activity focused on composite manufacture, GKN Aerospace is also involved with the recently launched 'Next Generation Composite Wing' (NGCW) research programme. In this complementary activity, the Company is working with 16 other leading British industrial and research organisations.

Here, GKN Aerospace's composites and ice protection teams are working on creating an optimal factory layout, examining new developments in tooling and advancing wing systems design and manufacturing integration.

Bamford continues: "Our challenge is to develop these promising new processes and developments and successfully apply them to produce more efficient structural components, reducing cost and weight and progressing airframe performance towards the challenging 2020 emissions reduction targets."