Aug 19 2008

Powtech 2008 (30 Sep – 2 Oct 2008; Nürnberg, Germany) will see the launch of a Hopper Design Software package for the Freeman Technology FT4 Powder Rheometer, adding a further dimension to the applications for this universal powder tester.

Drawing on the characterization capabilities of the FT4, the new software package improves access to well-established hopper design methodologies, speeding up and simplifying compilation and interpretation of the required data.

The two criteria defining the limits of a bin to operate in mass flow mode are outlet size and hopper half angle. Both are calculated using data generated from shear cell, wall friction and compressibility testing. All the required data can be generated simply and easily using the FT4 in a series of fully automated measurements taking approximately two hours.

The new software, which will become part of the FT4’s standard data analysis package, is supported by a step-by-step guide to hopper design, simplifying what has traditionally been a complex process.

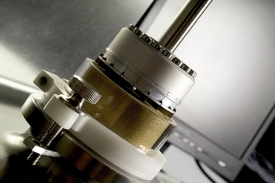

The FT4 Powder Rheometer is used across many powder processing industries. It delivers comprehensive powder flowability data that can be correlated with processing experience to aid efficient processing and quality control. It provides automated shear testing, dynamic flowability and bulk properties measurements making it a universal powder tester for formulators, process engineers and QA specialists.

For more information on rheometer, click here.