Jul 19 2010

Russian researchers with Siemens Corporate Technology (CT) are using special carbon nanoparticles to optimize materials.

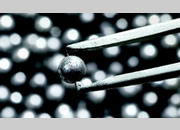

They are adding fullerenes—soccer ball-shaped molecules comprising 60 carbon atoms— to aluminum to obtain a new material that is roughly three times harder than conventional composites, yet weights much less. The lightweight yet strong aluminum could be used to improve the performance of compressors, turbochargers and engines.

Aluminum and C60 are ground under an argon atmosphere into tiny grains with a diameter of just a few nanometers, or millionths of a millimeter.

Aluminum and C60 are ground under an argon atmosphere into tiny grains with a diameter of just a few nanometers, or millionths of a millimeter.

The pure carbon fullerenes have high mechanical stability at a low weight. Aluminum and C60 are ground under an argon atmosphere into tiny grains with a diameter of just a few nanometers, or millionths of a millimeter. The two substances then bond with one another to form the new material. Special mills grind the aluminum, and the ultrafine powder is pressed into a new material. Roughly one percent by weight of fullerenes is sufficient to imbue the material with sufficient hardness.

Siemens envisages a variety of applications for the hard aluminum. Turbines with lighter rotors can deliver higher speeds and make compressors or engines more efficient. One could coat superconducting cables with the material to improve their stability. They would then be able to withstand stronger currents, which in turn would make machines such as magnetic resonance tomography scanners more powerful. Because fullerenes barely affect the electrical conductivity of the aluminum, aluminum electric cables could be made thinner to save material.

In another project, the CT researchers improved materials known as thermoelectricals. These generate an electric voltage from a temperature differential, thus producing energy from the waste heat of a device. Together with the Technological Institute for Superhard and Novel Carbon Materials (TISNCM) in Troisk outside of Moscow, they improved the performance of thermoelectricals by 20 percent. The fullerenes restrict the thermal conductivity and thus keep more of the heat to be converted in the material. The researchers expect to be able to generate around 50 watts of energy from a temperature differential of 100 degrees and a surface area of 100 square centimeters.