Aug 26 2010

Electronic products pollute our environment with a number of heavy metals before, during and after they're used. In the U.S. alone, an estimated 70% of heavy metals in landfill come from discarded electronics.

With flat screen TVs getting bigger and cheaper every year, environmental costs continue to mount.

To counter this, a new Tel Aviv University solution applies a discovery in nano-technology, based on self-assembled peptide nanotubes, to "green" the optics and electronics industry. Researchers Nadav Amdursky and Prof. Gil Rosenman of Tel Aviv University's Department of Electrical Engineering say their technology could make flat screen TV production green and can even make medical equipment –– like subcutaneous ultrasound devices –– more sensitive.

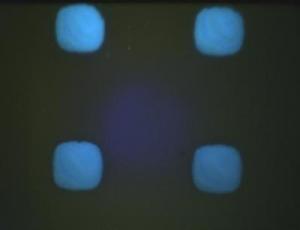

Organic LED lights were created in the Tel Aviv University lab.

Organic LED lights were created in the Tel Aviv University lab.

Inspired by a biomaterial involved in Alzheimer's disease research discovered by Prof. Ehud Gazit of the university's Department of Microbiology and Biotechnology, the scientists developed a new nano-material, applying the scientific disciplines of both biology and physics. This biological material is the basis for their new, environmentally-friendly variety of light-emitting diodes (LED) used in both consumer and medical electronics.

TV in a test tube?

Their new invention is more than a clean, green way to create light, the researchers say. It also generates a strong signal that can be used in other applications in the nano-world of motors, actuators and ultrasound.

"We are growing our own light sources," says Amdursky, a doctoral student working under Prof. Rosenman's supervision. The organic nano-lightsticks he and his supervisors have developed using organic chemistry are made from carbon, making them cheap as well as environmentally friendly.

Unlike conventional light sources, the biologically-derived light source has a nano-scale architecture, easing the integration into light-emitting devices such as LED TVs and improving the resolution of the picture as well. The Tel Aviv University team has recently written a patent to cover their "organic LED" lights.

From living rooms to hospital rooms

According to Amdursky, the light emitted by the new light sticks is not appreciably different than that which emanates from today's inorganically engineered LED lights.

"We don't need a special plant, bacterium or a big machine to grow these structures in," says Amdursky, who says the applications of the technology are wider than the widest screen television. The core technology and structures, described in Advanced Materials, Nano Letters, and ACS Nano, exhibit "piezoelectric characteristics," necessary for the development of tiny nano-ultrasound machines that could scan cells from inside the body. Piezoelectric motors or actuators are only dozens of nanometers wide, which can lead to their application in energy harvesting systems as super-capacitors –– large energy storage devices, necessary for the solar energy and wind energy business.