Nov 26 2010

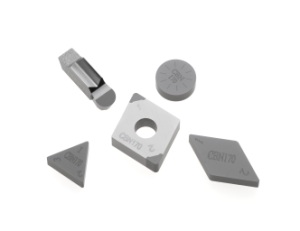

Seco Tools has announced the availability of its new CBN 170 grade, the first PCBN grade ever developed specifically for the finish turning of nickel-based super alloys commonly found in aerospace, power generation and automotive components.

Designed for both toughness and wear-resistance, CBN 170 works well in materials such as Inconel 718, UDIMET, Waspaloy, MAR M and others. In field tests run using CBN 170, it has increased tool life by 40% and cutting speed by 45% as compared to whisker ceramics.

Seco Tools new CBN 170 is the first grade ever designed specifically for the finish turning of nickel-based super alloys.

Seco Tools new CBN 170 is the first grade ever designed specifically for the finish turning of nickel-based super alloys.

Designed to satisfy the exacting surface finish, tolerance and length of cut requirements typically found in finishing operations for nickel-based super alloys, CBN 170 incorporates a unique whisker ceramic binder, which enhances tool life and reduces insert indexes. These whiskers of silicon carbide crystals add tensile strength and fracture toughness to the grade.

The new grade can be applied to finish machining of hardened and unhardened nickel-based superalloys from cast, forged, powdered metal or machined from solid source. It can achieve depths of cut up to 0.020” at cutting speeds of 900 – 1300 sfpm. Designed for continuous cutting applications, coolant must be applied to the operation.

To further enhance tool life, Seco recommends the use of its Jetstream tooling, which delivers coolant at high pressures close to the cutting edge, cooling the work area and producing smaller, hard, brittle chips.