Feb 1 2011

Recently released test results demonstrate that both PERMALAC 2K and PERMALAC EF, clearcoat lacquers manufactured by Peacock Labs in Philadelphia offer far greater weathering resistance than the the highly rated two-part coating used as the control.

The results were surprising, as the control has achieved general acceptance in the auto industry as an OEM coating. The testing was conducted by Innovative Technical Systems Corp. of Michigan.

PERMALAC UV Test Results

PERMALAC UV Test Results

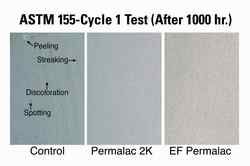

While the control product started demonstrating UV degradation in both the red & green scale and blue and yellow scale after 250 hours, the PERMALAC products maintained product and color integrity through 1000 hours of ASTM 155-cycle 1 testing.

The testing consisted of 1000 hours of xenon arc exposure and showed an average Delta E of 0.75 for the PERMALAC products as against an average Delta E of 1.5 for the control. Furthermore, neither the PERMALAC 2K nor the PERMALAC EF (an environmentally friendly product with only 170 g. of VOCs per liter) exhibited any alteration in physical quality or appearance visible to the naked eye. The control on the other hand exhibited clearly visible brown discoloration streaks after only 250 hours of xenon arc exposure.

PERMALAC products have been in use by professionals who require a clearcoat lacquer that protects a variety of substrates from extreme weather conditions for years. Having to strip and redo surfaces is costly and time consuming. That's why sculptors, sign makers, fence installers, and others like manufacturers of high end skate boards insist on PERMALAC products. There are PERMALAC coated installations that have withstood UV, wind-borne sand, salt spray, extremes of temperature and constant immersion in the Mississippi River for years without appearance alteration.