Mar 21 2011

Advanced Composites Group, JD Lincoln, GRPMS, Richmond Aerovac and IPM will be co-exhibiting under the Umeco Composites banner on Stand No.: T50 in Hall 1 at the JEC Composites exhibition on the 29th, 30th and 31st March 2011.

Umeco Composites, a division of Umeco plc, operates as two business streams, namely Umeco Composites Structural Materials (UCSM) and Umeco Composites Process Materials (UCPM):

- Umeco Composites Structural Materials (UCSM) businesses Advanced Composites Group (ACG), JD Lincoln and GRPMS provide a range of complementary products, services, design expertise and tooling solutions to the composites industry.

- Umeco Composites Process Materials (UCPM) businesses Richmond Aerovac, IPM and Med-Lab serve global industries by supplying a range of vacuum processing materials and protective films, consumable short shelf-life hazardous aviation goods, and electronic equipment for testing fuels and heavy oils.

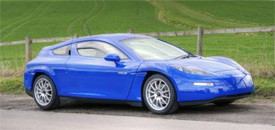

Delta E-4 Coupé - courtesy and ©Delta Motorsport Ltd.

Delta E-4 Coupé - courtesy and ©Delta Motorsport Ltd.

Each Umeco Composites business will display a range of exhibits, and personnel will be on hand to discuss individual product portfolios and technologies. The main exhibit on the stand will be Delta Motorsport's E-4 Coupé, a vehicle which has been manufactured using ACG's advanced automotive prepreg products.

Officially launched on March 7th at the European Automotive Industry Technology Roadshow, the E-4 Coupé is an all-electric road vehicle built using ACG's innovative DForm Deformable Composite System (DCS) for structures, next generation Body Panel System (BPS), and tooling prepreg materials. Delta worked with ACG on the carbon fibre integrated chassis and bodywork construction to generate a class-leading, low-mass vehicle together with a clear road map towards effective medium-volume production. The four-seater road car has been developed using a combination of ACG's DForm DCS and next generation BPS, and has been engineered with a high level of parts integration in order to achieve maximum weight reduction compared with traditional materials. The Body in White (BIW) is manufactured from just fifteen bonded major composite panels and weighs only 85Kg, including the front and rear aluminium sub-frames, and crash structures.

Closures have been manufactured using carbon DForm for the internal panels and either glass or carbon BPS for the outer skins. This approach dispensed with the need to attach additional trim covers, which would have added weight to the vehicle and reduced that all-important mileage range.

The car also used a range of ACG's prepregs systems for aesthetically pleasing seats. These prepregs use a range of high performance resins combined with woven, stitched and unidirectional fibre formats. With assistance from its carbon fibre fabric weavers, ACG has developed a Special Visual Quality (SVQ) material specification that maximises the aesthetic impact of carbon fibre finishes, ensuring that its products meet the exacting requirements set by the automotive interiors industry.

ACG's in-house moulding facility and KS Composites, Delta's moulding partner, manufactured the prototype parts using ACG's single-sided DForm tooling, a product which is custom-formatted to produce the optimum, paint-ready surface finish direct from the mould. DForm composite tooling offers a number of advantages over standard long fibre woven fabric prepreg, and random short fibre and infusion tooling systems, and can offer savings of up to 30% in lay-up time. Its unidirectional fibre structure maintains dimensional accuracy and performance predictability. DForm creates an extremely flat, print-through-free surface profile with no local thinning, no loss of fibre orientation or variation in resin content.

Building on the success of its BPS240 Body Panel System, which is widely used by supercar constructors, ACG will be exhibiting an example of its new MkII BPS in the form of a boot lid. Targeted squarely at the medium to high volume market, where press mould processing is paramount, the innovative format further utilises DForm technology. ACG's believes that this will play a major part in the development of rapid composites processing technology.

ACG's MkII body panel system de-skills and reduces laminating time, and facilitates the production of flat surface profiles with minimal print-through, thus minimising surface preparation and reducing costs at all stages of manufacturing.

An award winning, innovative tooling solution, jointly developed by ACG and Integran Technologies Inc., will be on display in the JEC Innovations area. ACG and Integran won the JEC 2011 Composite Innovation Award - Equipment Category for Carbovar - Nanovate -NV surface composite tooling. The innovation combines the hardness, durability and damage tolerance of the nanometal coating with the lightweight, low thermal mass of a carbon fibre composite mould tool to deliver a durable and cost effective solution.

The Nanovate surface is an ultra-hard, nanocrystalline nickel/iron alloy coating that has a low coefficient of thermal expansion (CTE) matching the CTE of the composite mould tool. The ultra-hard surface increases the longevity of the mould, becoming comparable to that of a conventional metallic mould tool. Composite tooling saves the energy required for the heat-up and cool-down phases, and the energy required to lift, rotate and manoeuvre them within the working environment, and during the lay-up process (faster material deposition rates).