BTU International, a producer of sophisticated thermal processing equipment for the electronics and alternative energy sectors, has launched a metallization firing system, the TRITAN HV90 for silicon photovoltaics.

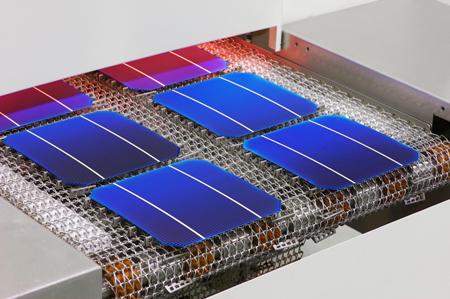

BTU Tritan InLine Processing MedRes

BTU Tritan InLine Processing MedRes

The dual-lane system has exclusive characteristics of volatile organic compound (VOC) abatement, edge belt, 3600 wafers per hour and one zone spike with a spike time less than 3s.

Product marketing manager at BTU for metallization products, Bob Bouchard stated that the TRITAN is a firing furnace with dual-lane feature that is suited for bulk manufacture. In order to achieve a lesser cost for each watt, it is important to adopt dual-lane processing. Customers adopting this technology can anticipate a 35% enhancement of capital efficiency and the system’s excellent performance in lane to lane comparison ensures that it is a great technology to adopt, added Bouchard.

One of the exclusive features of the metallization firing system is BTU’s innovative TriSpeed technology, enabling users to benefit from high ramp rates and not compromise with the cooling and drying sections of the profile. The three-speed, three-belt system enables superior control of profile development. In the test runs, the TRITAN has been highly consistent in displaying an improved fill factor proving increased efficiency. Since the TRITAN also has a less cost of ownership, customers can attain a minimum cost per watt. The system will be displayed at PV Taiwan 2011.