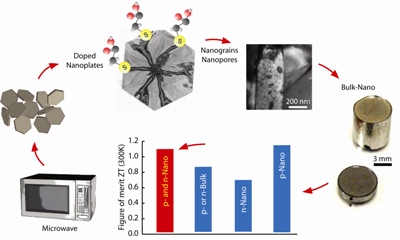

A research team led by Ganpati Ramanath from Rensselaer Polytechnic Institute have devised a novel method for synthesizing innovative nanomaterials using a typical microwave oven and trace amounts of sulfur, paving the way to develop low-cost, superior-performance solid-state air conditioners and refrigerators without moving parts and refrigerants.

Rensselaer Polytechnic Institute researchers have developed a novel method to produce advanced nanomaterials. Credit: Rensselaer/Ramanath

Rensselaer Polytechnic Institute researchers have developed a novel method to produce advanced nanomaterials. Credit: Rensselaer/Ramanath

The research is based on the idea of incorporating a dash of nanoscale sulfur as a dopant onto nanostructured thermoelectric materials. The doped material is produced by cooking the dopant and the thermoelectric material in a standard microwave oven. Pea-sized pellets are then produced from the resulting powder by applying pressure and heat in such a manner that retains the properties caused by doping and nanostructuring.

Properties of these pellets are superior to that of existing difficult-to-produce thermoelectric materials. Moreover, this novel method of producing the doped pellets is user-friendly, low-cost and rapid when compared to traditional thermoelectric material production processes. This method also reduces the interdependence of Seebeck coefficient, thermal conductivity and electrical conductivity of thermoelectric materials by integrating nanostructuring and doping in familiar thermoelectric materials, including selenides and tellurides based on antimony and bismuth.

The objective of altering these three properties is to produce a thermoelectric material having a high figure of merit or ZT that measures the material’s conversion efficiency from heat to electricity. The novel nanomaterials synthesized by the research team have high ZT values of 1-1.1 at room temperature. The team believes that nanomaterials with even higher ZT can be produced by optimizing the process with smart engineering.

This innovative method is capable of producing both n-type and p-type thermoelectric nanomaterials with a superior ZT. It produces 10-15 g of the doped nanomaterial within in 2-5 min using the standard microwave oven. Industrial-scale microwave ovens can be used for the mass production of the doped nanomaterials.