Ryan Hayward, Christian Santangelo and colleagues, researchers from the University of Massachusetts Amherst have recently used polymer science and photographic methods for creating a new method that will help print 2-D polymer sheets, which can be folded into 3-D shapes, with the addition of water. The new method may find applications from medicine to robotics.

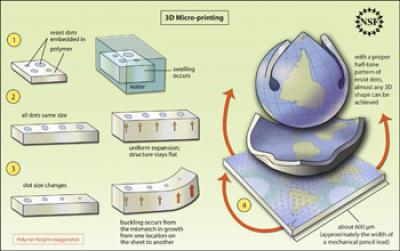

Researchers have determined how to control the shape of a polymer system at the micro-scale with a technique akin to half-tone printing. The polymer they use swells like a microscopic sponge when exposed to water, however printing "resist dots" in the polymer substrate creates points that will not swell (1). When all resist dots in one area are the same size, the area undergoes uniform expansion and the structure remains flat (2). When the dot size changes, however, buckling occurs from the mismatch in growth from one area to another (3).

Researchers have determined how to control the shape of a polymer system at the micro-scale with a technique akin to half-tone printing. The polymer they use swells like a microscopic sponge when exposed to water, however printing "resist dots" in the polymer substrate creates points that will not swell (1). When all resist dots in one area are the same size, the area undergoes uniform expansion and the structure remains flat (2). When the dot size changes, however, buckling occurs from the mismatch in growth from one area to another (3).

An ultraviolet (UV) light and a photomask were utilized by the scientists for printing a pattern on polymer sheets. This technique is called as photolithography. When the polymer is not exposed to the UV light, it will uniformly swell and expand, when water is added. When the UV light is focused on the polymer molecules within the sheet, it is rigidly linked together at several points. This cross link avoided the expansion of the polymer molecules during the addition of water. By controlling the cross link patterning across the complete sheet, the scientists were able to control the amount of swelling at each area. Specific three dimensional shapes were created through the second exposure of a selected UV light pattern.

The work is a shared effort between physics and polymer engineering. It was helped by the National Science Foundation (NSF) Faculty Early Career Development and Materials Research Science and Engineering Centers awards.

According to Daryl Hess, NSF’s program director in the division of materials research stated that this paper has reported a mixture of experimental theory and techniques for developing a new method of making self-actuating materials, which will result in a desired 3-D shape.