ACD, a provider of physical design, printed circuit board (PCB) fabrication, parts procurement, assembly and test services for the electronics industry, has added a PDR IR-E3 Evolution 2000 BGA Rework System to its portfolio.

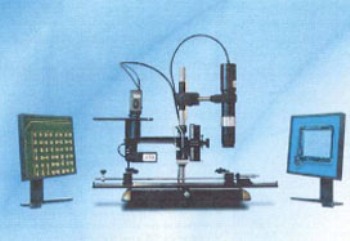

PDR IR-E3 Evolution 2000 BGA Rework System

PDR IR-E3 Evolution 2000 BGA Rework System

The system is fabricated mainly to handle the repairing challenges of existing PCB assemblies by employing PDR’s patented focused infra-red (IR) technology.

The system helps the company to achieve 100% yield ball grid array (BGA) rework with no complications. In addition, it offer exceptionally high levels of process controls and profiling for the efficient rework of the most cutting-edge packages, including flip chips, quad-flat no-leads packages (QFNs), chip scale packages (CSPs), BGAs and surface-mount packages(SMDs). The PDR IR-E3 SMT/BGA rework station is also ideal for 0201 and lead-free applications.

The focused IR rework stations from PDR offer high quality results on all lead-free devices, array packages and standard and fine-pitch parts. The stations have the capability to locate the smallest component in a complex environment and deliver a clear view to the operator throughout the process. Scott Fillebrown, President and CEO of ACD, remarked that the purchase of focused IR rework station from PDR enhances the company’s capability to offer BGA rework services and helps to compete in the market.