The EXPERT 04.6 rework station series has been successfully expanded by MARTIN with a novel configuration that will help in the rework of power components and LEDs on heavy ceramic or metal boards.

Martin PI04 Bild Expert 04 06 IXM

Martin PI04 Bild Expert 04 06 IXM

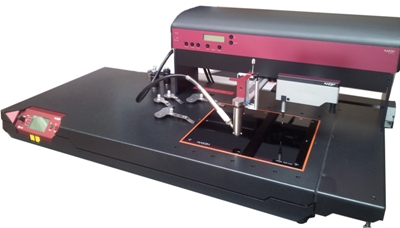

SMT Nuremburg 2012 first showcased the new EXPERT 04.6IXM, which attracted a lot of attention. One-sided PCBs are arranged on a glass plated heated using IR radiators with ratings up to 3000 W. This causes heating at very high speeds even if large ceramic or aluminium substrates are processed. The size range is between 30x30 and 300x300 mm. The system is designed for applications in which substrates must be heated without overshoot and upto temperatures of 200°C. For instance, LED rework requires high substrate temperatures for removing and replacing individual components from an array.

The system has two manipulator arms each having a movement lock, each of which carry the hot air solder pen and the placement tool in order to span the complete working area. The system enables effortless picking of tiny components from a dispenser and accurately places them on the PCB by aligning them manually. Accurate supply of hot air to solder joints is possible using optimized solder tools to render gentle heating. Once the reflow process is completely integrated, vacuum cups lift the components from the molten solder. Double-sided boards can also be processed easily. Magnetic support holders support the boards just above the heating plate, enabling freedom and flexibility for customization of processes.

Similar to other EXPERT systems in the same family, this model has residual solder dispensing and removal. Especially during rework of LEDs, re-depositing and cleaning solder are crucial steps which can be performed ergonomically with this system.

The Autoprofiler and the Easy-Solder software support users in archiving, establishing and executing profiles. Accurate heat management offers the consistency desired in a MARTIN system.