Jul 7 2014

Takenaka Corporation, in collaboration with the National Institute for Materials Science (hereafter referred to as NIMS) and Awaji Materia Co., Ltd., jointly developed vibration dampers made of a new alloy, which has about 10 times longer low-cycle fatigue life than the steel material in common use today for vibration dampers.

Abstract

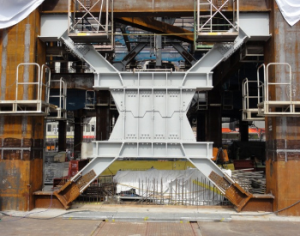

An Fe-Mn-Si based vibration damper unit

An Fe-Mn-Si based vibration damper unit

Takenaka Corporation (Masahiro Miyashita, president), in collaboration with NIMS (Sukekatsu Ushioda, president) and Awaji Materia Co., Ltd. (Takahiko Mio, president), jointly developed vibration dampers made of a new alloy (patent application submitted), which has about 10 times longer fatigue life than the steel material (low yield strength steel) commonly used today for vibration dampers.

The new vibration damper stably maintains its performance even after being subjected to repeated deformations caused by a long-period and long-duration earthquake, and greatly improves the seismic safety margin.

As the damping source of this vibration damper, we used a new Fe-Mn-Si-based alloy which was developed at NIMS by adding highly concentrated manganese and silicon to iron, the main ingredient. This alloy not only possesses excellent fatigue durability but also superb ductility and corrosion resistance.

In the process of developing this vibration damper, Takenaka Corporation designed the optimal shape and assessed the performance of the damper containing the new alloy as the damping source. In addition, Awaji Materia developed technology to manufacture the new alloy which is difficult to melt and process. And Nippon Koshuha Steel Co., Ltd. (Masahiro Kawase, president) for the first time melted an Fe-Mn-Si based alloy in an electric furnace in order to increase its scale and mass produce it, and manufactured material plates for use as a vibration damper.

JP Tower Nagoya (Nagoya City, Aichi Prefecture), which is expected to be completed in November 2015, is installed with 16 vibration damper units we developed, with each damper weighing as much as 4000 kN in the lower section (1st to 4th floor) of the tower.

In the future, based on the BCP (business continuity planning) guidelines, we plan to use this vibration damper suitably in combination with conventional dampers such as oil dampers and friction dampers in order to protect high-rise buildings from long-period and long-duration earthquakes.