Mar 10 2015

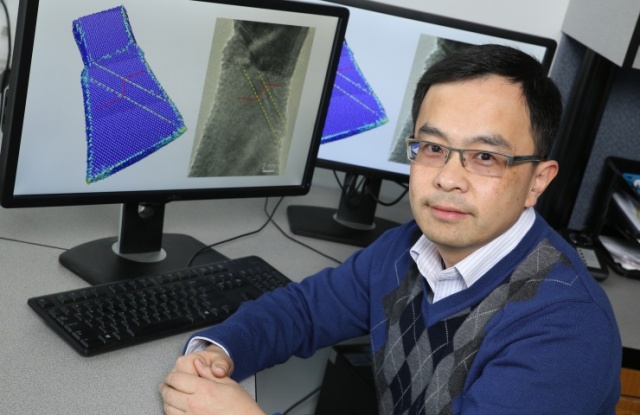

Ting Zhu, an associate professor in Georgia Tech’s Woodruff School of Mechanical Engineering, worked with colleagues at the University of Pittsburgh and Drexel University to develop a better understanding of a key deformation mechanism in nanoscale tungsten. (Credit: Candler Hobbs)

Ting Zhu, an associate professor in Georgia Tech’s Woodruff School of Mechanical Engineering, worked with colleagues at the University of Pittsburgh and Drexel University to develop a better understanding of a key deformation mechanism in nanoscale tungsten. (Credit: Candler Hobbs)

Researchers at the Drexel University, the University of Pittsburgh and the Georgia Institute of Technology have discovered a new method to view and analyze atomic-scale deformation mechanisms. In the process, they spotted an exciting phenomenon in a common material, tungsten.

The team is the first to detect atomic-level deformation twinning in body-centered cubic (BCC) tungsten nanocrystals. A thorough comprehension of the behavior of nanomaterials will be possible only by understanding these mechanisms that decide their structure and, subsequently their function and strength.

To achieve the detection of atomic-level deformation twinning, the research team used high-resolution transmission electron microscope (TEM) and advanced computer modeling. Their findings are published in the journal Nature Materials, March 9th issue, and it represents a landmark in the in-situ study of mechanical behavior of nanomaterials.

Deformation twinning is a deformation type, which works along with dislocation slip, to allow materials to permanently deform without breaking. During twinning, the crystal tends to reorient, thus creating an area in the crystal that is a mirror image of the original crystal. Twinning has been noticed earlier in large-scale BCC metals and alloys at the time of deformation. However, occurrence of twinning in BCC nanomaterials remains to be unknown.

To gain a deep understanding of deformation in BCC nanomaterials, we combined atomic-scale imaging and simulations to show that twinning activities dominated for most loading conditions, due to the lack of other shear deformation mechanisms in nanoscale BCC lattices.

Scott Mao, a professor in the Swanson School of Engineering at the University of Pittsburgh

The research team selected tungsten as a basic BCC crystal. Tungsten is widely used as filaments for light bulbs. The atomic-scale twinning was studied inside a TEM. Earlier this would not have been possible as TEM imaging required BCC samples less than 100nm in size, which was difficult to make.

Mao, the lead author of the paper and Jiangwei Wang, a graduate student at University of Pittsburgh fabricated a unique way of making the BCC tungsten nanowires. Under a high-resolution TEM, Wang welded two small pieces of separate nanoscale tungsten crystals together to produce a 20nm diameter wire. This wire was strong enough to compress and stretch while Wang analyzed the twinning phenomenon in real time using the TEM.

To further comprehend the phenomenon studied by Mao and Wang’s team at the University of Pittsburgh, Christopher Weinberger, an assistant professor in Drexel’s College of Engineering, built computer models that display the mechanical behavior of the tungsten nanostructure – at the atomic level.

Weinberger’s model allowed the team to observe the physical factors at play during the twinning process. This data will assist researchers in speculating why it occurs in nanoscale tungsten and plan a course for probing this behavior in other BCC materials.

We’re trying to see if our atomistic-based model behaves in the same way as the tungsten sample used in the experiments, which can then help to explain the mechanisms that allow it to behave that way. Specifically, we’d like to explain why it exhibits this twinning ability as a nanostructure, but not as a bulk metal.

Christopher Weinberger

Assistant Professor in Drexel’s College of Engineering

Along with Weinberger’s modeling, Ting Zhu, an associate professor in the Woodruff School of Mechanical Engineering at Georgia Tech, and Zhi Zeng a graduate student, performed advanced computer simulations using molecular dynamics to learn about deformation processes in 3D.

Zhu’s simulation however showed that tungsten’s “smaller is stronger” behavior has its drawbacks at the application stage.

“If you reduce the size to the nanometer scale, you can increase strength by several orders or magnitude,” Zhu said. “But the price you pay is a dramatic decrease in the ductility. We want to increase the strength without compromising the ductility in developing these nanostructured metals and alloys. To reach this objective, we need to understand the controlling deformation mechanisms.”

The twinning mechanism, Mao added, contrasts with the conventional wisdom of dislocation nucleation-controlled plasticity in nanomaterials. The outcome is likely to motivate further experimental and modeling examination of deformation mechanisms in nanoscale metals and alloys, thereby eventually enabling the design of nanostructured materials to completely comprehend their latent mechanical strength.

"Our discovery of the twinning dominated deformation also opens up possibilities of enhancing ductility by engineering twin structures in nanoscale BCC crystals", Zhu said.