Mar 27 2015

Walter Voit, Ph.D., of the University of Texas at Dallas (UT Dallas) along with co-researchers has successfully incorporated carbon nanotubes and “buckyball” clusters in PVDF material to improve its electricity-generating properties.This PVDF plastic will be reported at the 249th National Meeting & Exposition of the American Chemical Society (ACS).

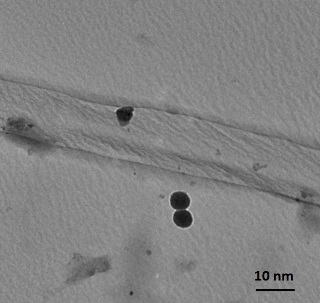

Carbon nanotubes (one shown above) and “buckyball” clusters (dark spots) are incorporated in a new material to boost its electricity-generating properties. Credit:Voit lab

Carbon nanotubes (one shown above) and “buckyball” clusters (dark spots) are incorporated in a new material to boost its electricity-generating properties. Credit:Voit lab

There is a strange characteristic of a plastic used in tubing and filters. Electricity can be generated during elongation or compression. Until now, this ability has been used only in a minor way, however, researchers are twisting plastic fibres to generate more electricity for a broad application range spanning from artificial muscles to green energy.

“For the past couple of years, we’ve been doing a lot of work with a material called PVDF — polyvinylidene fluoride,” explains Walter Voit, Ph.D., of the University of Texas at Dallas (UT Dallas). “If we produce it under precise conditions, we can make it piezoelectric, which means if I stretch it, it generates electricity. Or I can put electricity onto the surface of the material and make it change shape.”

PVDF, and similar materials, are already being deployed in modern technology in the form of tilt sensors in electronics and pressure sensors in touchpads. However, it is believed that if they are found to possess significant piezoelectric properties, their potential could surpass these simple applications.

Voit, along with Shashank Priya, Ph.D., at Virginia Polytechnic Institute and State University, has already made new advancements toward this target. They have dominated efforts to develop polymer-based 'soft' energy harvesting materials as part of the Center for Energy Harvesting Materials and Systems, a National Science Foundation (NSF) program aimed at developing motion-control and energy-capture technologies.

A doctoral student in Voit’s lab, Cary Baur, has found a way to deploy organic nanostructures called buckyballs and single-walled carbon nanotubes into PVDF fibers in order to double its piezoelectric performance. Buckyballs are small carbon atom spheres. They and their cylindrical counterparts have interesting characteristics, which are being used by scientists in a variety of ways.

It was observed that in Voit’s materials, the carbon nanostructures even out and improve the electric field strength. This has resulted in the PVDF-carbon hybrids becoming the most ideal piezoelectric composites reported till date in scientific documents, according to Voit.

In order to transform this yarn-like configuration into artificial muscles, or materials capable of relaxing or contracting in response to an electronic current, Voit had to make them more powerful. One way of doing this was achieved by a UT Dallas colleague.

Ray Baughman, Ph.D., wound a bunch of nylon fibers of width around ten strands of human hair into a tight long coil similar to a conventional telephone cord, however at a much smaller degree. That structure was capable of almost 50% contraction on heating and could lift 16 lbs.

“The effect is similar to twisting a rubber band,” Voit says. “If you pull on it when it’s coiled, you get a lot more strain on the rubber band than if it’s just straight.”

Voit is attempting to develop a similar impact for his PVDF-carbon fibers, which have improved piezoelectric properties in comparison with nylon, and contract in response to an electric current. “We have to coil it,” he says. “We have to have the right piezoelectric properties after it’s in that complex shape. That’s the real secret sauce that we think we can pull off. Ultimately, it could be used to build synthetic muscles that could make prosthetic limbs more life-like.”

Energy harvesting is another prospective application for Voit’s materials, which has attracted commercial interest. Boeing, which provided funds for a part of his research, is looking at a solution that would help energy generation from simple passenger activities such as sitting, standing and adjusting in their seats and use that to power certain functions in the plane, like cabin overhead lights. Voit states that by this some cables would be eliminated, adding considerably to the jet weight and save fuel.

“Now we’re finding ways to make this more processable at larger scales to enable larger energy harvesting apparatuses and practical artificial muscles,” Voit says.

Further to Boeing's funding, Voit also received funding for this work from the Defense Advanced Research Projects Agency, UT Dallas, NSF and Texas Instruments.