Jul 6 2015

The use of smart materials in solar thermal collectors is becoming increasingly popular. A research team from EPFL has produced a coating that can both absorb and radiate heat. This invisible process prevents energy from being over-produced and the facilities from being overheated.

The major applications of solar thermal collectors include home heating and production of hot water. The energy absorbed by the collectors can be used during the colder seasons. However, the collectors get overheated during summer and generate enormous heat. The problem of overheating, which can lead to damage in the facilities, remained unresolved until now.

The research team, led by Andreas Schüler, has created a smart material with properties that can be varied according to temperature. The material enables the collector to radiate excess energy, thereby preventing overheating during summer.

It is necessary for the tanks and other elements of solar panels to tolerate extremely high temperatures, even up to 180ºC during summer. The heat transfer fluid tends to degrade over time. This affects the sensors, the thermal insulation and the absorbent layer, making them inefficient. An “ideal” solar panel would be capable of absorbing heat up to a certain limit, and radiating the excess heat rays, like a mirror, to avoid overheating. “A mirror doesn’t absorb heat. That’s why mountain rescue blankets have aluminum coating. But we also need absorbent elements,” said Andrea Schüler.

Thermochromism and selective effect

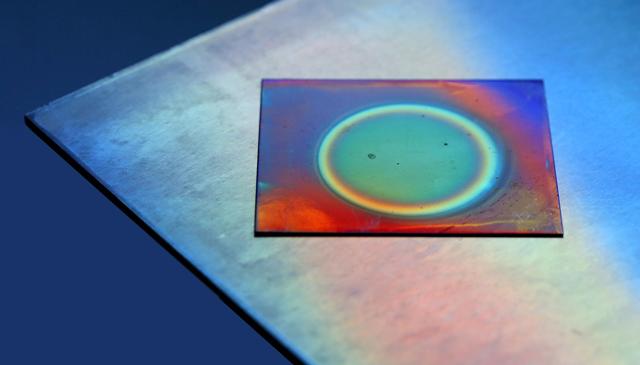

EPFL’s Solar Energy and Building Physics Laboratory (LESO-PB) is involved in “doping” the material to optimize the transition temperature, such that the material acts as a “bad” metallic conductor at elevated temperatures and a “good” semiconductor at lower temperatures. “With a coating of this material on a metallic substrate, one can get a surface that has a low thermal emissivity in a cold state and high thermal emissivity in a hot one,” explained the researcher.

The LESO-PB researchers focus on materials with reflective characteristics in the infrared range and absorbent characteristics in the solar spectrum, based on the wavelength. This is known as the selective effect. The project’s actual concept is to successfully combine a selective effect with a thermochromic function where the color reacts and changes according to heat, which is a phase change taking place at 68 °C. The new technique allows efficient absorption of heat by minimizing the effects of overheating.