May 4 2016

Pure calcite is a weak, fragile mineral that is generally present in chalk. As such, construction engineers do not prefer to use this mineral as a building material. However, if calcite is reinforced by a factor of two or more, similar to the way a mollusk has done to protect itself from predators through an evolutionary process, it could be a suitable building material.

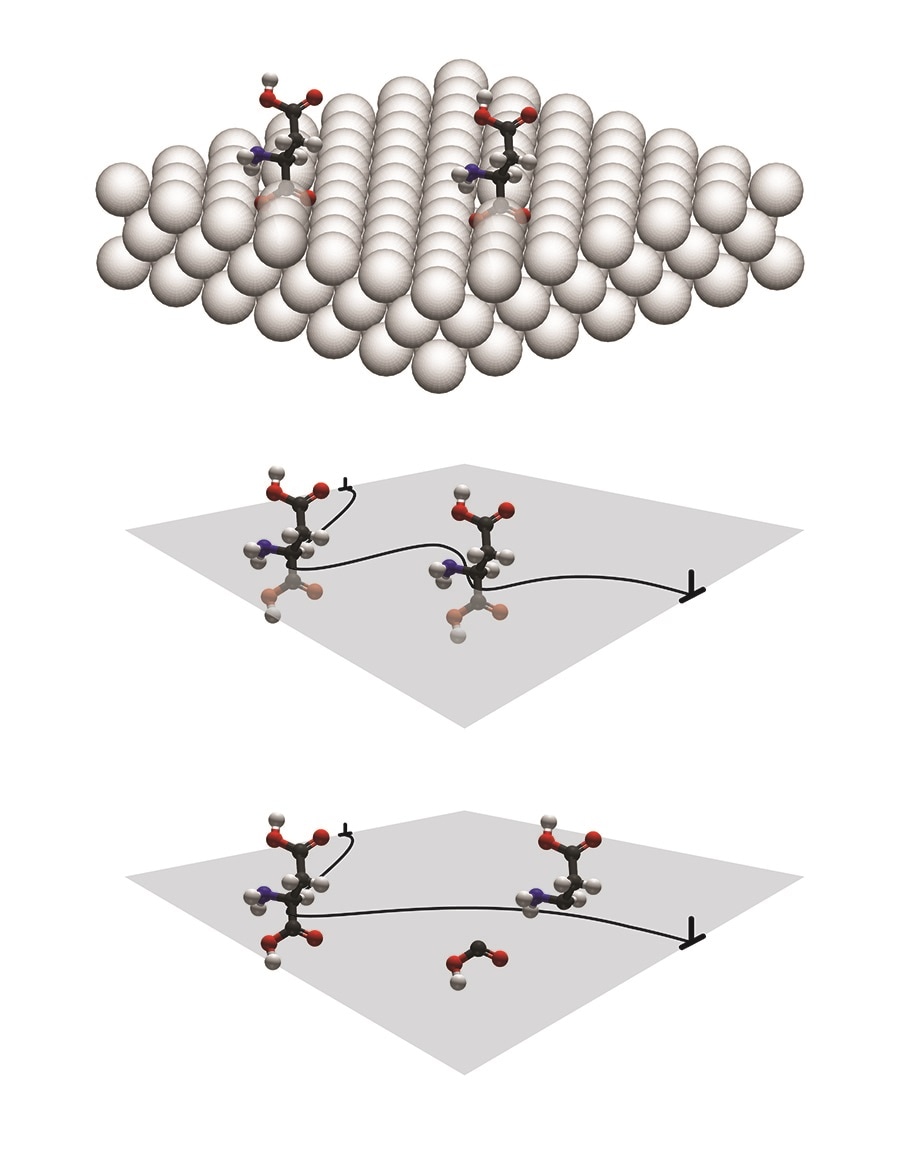

Top: Aspartic acid molecules embedded in a crystalline lattice. Middle: A dislocation in the crystal, represented by the black line, gets hung up on the molecules. Bottom: The dislocation cuts one of the molecules. The strength of a covalent bond in the molecule ultimately determines the hardness of the crystal. (credit: Nicole Wiles)

Top: Aspartic acid molecules embedded in a crystalline lattice. Middle: A dislocation in the crystal, represented by the black line, gets hung up on the molecules. Bottom: The dislocation cuts one of the molecules. The strength of a covalent bond in the molecule ultimately determines the hardness of the crystal. (credit: Nicole Wiles)

However, for construction engineers, hardened calcite would still not be a preferred material of choice for building homes. However, this mineral can be used in other applications based on its availability, and can provide a suitable alternative for low-strength fabrication requirements.

An international group of researchers from Cornell University and the University of Leeds (U.K.) have collaborated on an expansive study, which revealed that the addition of amino acids helps to control and increase the deformation resistance in pure calcite. The paper titled, “Tuning hardness in calcite by incorporation of amino acids,” is featured in Nature Materials.

Why is it that a mollusk at the bottom of the ocean can make a single crystal of calcite that’s solidly twice as hard as a naturally occurring, pure geologic calcite?

Shefford Baker, Associate Professor, Department of Materials Science and Engineering, Cornell University

This was the question Baker and Lara Estroff, also an associate professor of materials science and engineering and a member of the Kavli Institute at Cornell for Nanoscale Science, had attempted to resolve through several years of study. They worked with an international group of researchers, and the study was co-led by Yi-Yeoun Kim and Fiona Meldrum from Leeds. Other collaborators included former grad student Miki Kunitake and current Cornell graduate student Joseph Carloni, both of whom were mutually advised by Baker and Estroff, and nine others from Israel and the UK.

I don’t think there’s any way that all of these teams, having done their parts in isolation, could have come up with this paper. I don’t think all the connections would have been understood.

Shefford Baker, Associate Professor, Department of Materials Science and Engineering, Cornell University

The solution lies in amino acids like glycine (Gly) and aspartic acid (Asp), which when introduced in accurate, controlled quantities, increased the hardness of single-crystal calcite to values similar to naturally occurring biogenic calcite. In order to simulate the model biominerals, single-crystal calcite samples were grown in a solution containing Gly or Asp, the quantity of amino acid found in the mineral based on the molecular concentration of the solution. This experiment was carried out by the Meldrum group.

This was really a breakthrough, to be able to have controlled and very well quantified amounts of amino acids within single crystals.

Lara Estroff, Associate Professor, Department of Materials Science and Engineering, Cornell University

Unique methods and the combined expertise of many researchers were required to characterize the structure of these crystals. Kirsty Penkman’s team (University of York) were able to accurately measure the amino acid concentration within the calcite crystals, and Melinda Duer’s team (University of Cambridge) showed that the molecules were separately distributed instead of being distributed in clumps.

Another research team, headed by John Harding (University of Sheffield), performed atomistic computer simulations to find out how the molecules of amino acid can be accommodated within the calcite lattice. Kim, together with researchers at the Diamond Light Source (U.K.) and Boaz Pokroy (Technion), characterized the distortions caused by the molecules in the calcite lattice.

The Cornell team used this data to determine how far apart the molecules are from each other in terms of nanometers, and then compared the hardness determined by nanoindentation. The team eventually demonstrated that hardness was measured by the force required to break or cut the covalent bonds present inside the amino acids. To date, the hardness of the prototype biominerals was the largest to be ever reported in synthetic calcite and corresponds with those quantified in biogenic calcites.

This certainly opens up the door for us to think about how hard calcite could be made. Now that we’re starting to understand the control mechanisms, the question is, could we make a system in which we go further than this?

Shefford Baker, Associate Professor, Department of Materials Science and Engineering, Cornell University

The Cornell Center for Materials Research Shared Facilities, supported by the National Science Foundation (NSF), was used for the research. The study was funded by grants from the NSF and the Engineering and Physical Sciences Research Council (U.K.).