May 18 2016

“Flat” and “rigid” are terms that are traditionally used to explain electronic devices. However, the rise in demand for wearable and flexible electronics, antennas, biomedical devices, and sensors has led a group of researchers at Harvard’s John A. Paulson School of Engineering and Applied Sciences (SEAS) and Wyss Institute for Biologically Inspired Engineering to invent a novel way of printing intricate metallic architectures – as if they are suspended in midair.

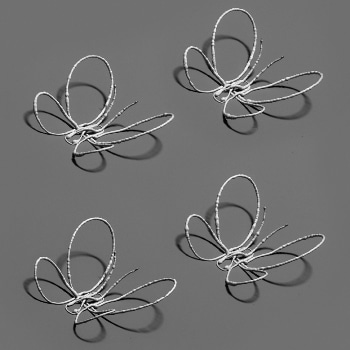

Laser-assisted direct ink writing allowed this delicate 3D butterfly to be printed without any auxiliary support structure (Image courtesy of the Lewis Lab/Harvard University)

Laser-assisted direct ink writing allowed this delicate 3D butterfly to be printed without any auxiliary support structure (Image courtesy of the Lewis Lab/Harvard University)

Described online in the Proceedings of the National Academy of Sciences, May 16, this laser-assisted direct ink writing technique permits metallic microscopic, free-standing 3D structures to be printed in a single step, devoid of auxiliary support material. The study was initiated by Jennifer Lewis, the Hansjörg Wyss Professor of Biologically Inspired Engineering at SEAS and Wyss Core Faculty member.

I am truly excited by this latest advance from our lab, which allows one to 3D print and anneal flexible metal electrodes and complex architectures ‘on-the-fly’.

Jennifer Lewis, Hansjörg Wyss Professor of Biologically Inspired Engineering, SEAS

Lewis’ group utilized an ink containing silver nanoparticles, directing it through a printing nozzle and subsequently annealing it with an accurately programmed laser that applies the correct amount of energy to initiate the solidification of the ink. This printing nozzle travels along x, y, and z axes and is joined with a rotary print stage to allow freeform curvature. In this manner, spiral motifs, small hemispherical shapes, and even a butterfly composed of silver wires measuring less than a hair’s width can be printed within seconds in free space. The printed wires show exceptional electrical conductivity, which is nearly equivalent to that of bulk silver.

In comparison to conventional 3D printing methods utilized to construct conductive metallic structures, laser-assisted direct ink writing is not only superior in its capability to create complex, curvilinear wire patterns in a single step, but also so that confined laser heating permits electrically conductive silver wires to be printed on cheap plastic substrates directly.

According to Mark Skylar-Scott, Ph.D., the study’s first author, Wyss Institute Postdoctoral Fellow, optimizing the nozzle-to-laser separation distance was the most difficult aspect of refining the technique.

If the laser gets too close to the nozzle during printing, heat is conducted upstream which clogs the nozzle with solidified ink. To address this, we devised a heat transfer model to account for temperature distribution along a given silver wire pattern, allowing us to modulate the printing speed and distance between the nozzle and laser to elegantly control the laser annealing process ‘on the fly'.

Mark Skylar-Scott, PhD., Postdoctoral Fellow, Wyss Institute

The outcome is that the technique can create spirals and sweeping curves, in addition to directional changes and sharp angular turns written with silver inks into thin air, paving the way for unlimited potential applications in biomedical and electronic devices that depend on custom-made metallic architectures.

Apart from Lewis and Skylar-Scott, Suman Gunasekaran, an undergraduate researcher studying chemistry and physics at SEAS is the co-author of this study.

The U.S. Department of Energy, Office of Science, Office of Basic Energy supported this work.