Jun 3 2016

According to Penn State scientists, polymer membranes, which are patterned for enhanced performance, can now be prototyped and tested with a new kind of 3D printing.

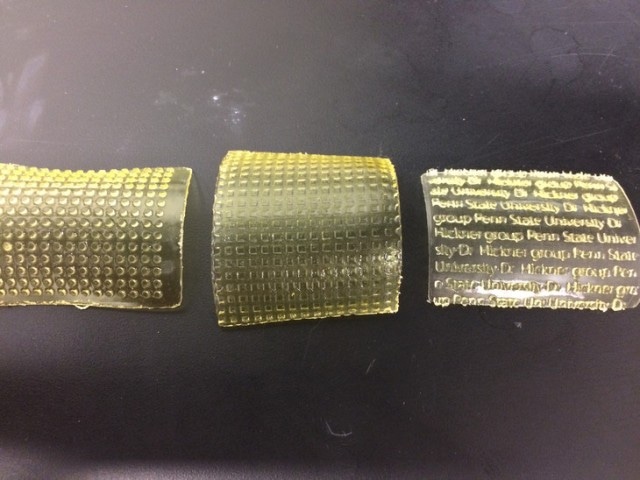

Patterned membranes created by 3D printing. (Image- Hickner Group/Penn State)

Patterned membranes created by 3D printing. (Image- Hickner Group/Penn State)

Specific batteries, fuel cells, purification and desalination of water, heavy metal removal and processing of food require the use of ion exchange membranes. These membranes are mostly flat, thin sheets just like the plastic wrap found in kitchen drawers. A recent study has proved that amazing hydrodynamic properties arise when 3D patterns are created atop 2D membrane surfaces. These properties can enhance the transport of ions or alleviate fouling which is a major drawback in most membrane applications.

Generally, the silicon mold is engraved with the required pattern and poured into the polymer to make the patterned membranes, also known as profiled membranes. It is then left undisturbed till it hardens. This process is laborious, costly, time consuming, and gives rise to a single pattern type.

We thought if we could use 3D printing to fabricate our custom-synthesized ion exchange membranes, we could make any sort of pattern and we could make it quickly.

Michael Hickner, Associate Professor of materials science and engineering, Penn State.

Hickner and his group explained about the creation of a custom 3D photolithographic printing process that shares a comparable idea with stereolithography - an existing 3D process. The details of this study are published in the American Chemical Society's journal ACS Applied Materials and Interfaces.

The researchers created a photocurable mixture of ionic polymers and subjected it to a light projector to make the base hard. Additional polymer was then added and a pattern was projected on the novel material to specifically harden the surface. The membrane conductivity was increased by a factor of two or three due to the surface pattern.

Membranes act like a resistor in a battery or fuel cell. If you can lower the resistance by a factor of two or three, you've really got something useful.

Michael Hickner

Jiho Seo, a Ph.D. candidate in materials science and engineering and the lead author of the paper, said, "While surface-patterned membranes have been studied previously, this is the first 3D printed example of these structures and the first model that really explains the resistance decrease in a quantitative way. A simple parallel resistance model describes the effect of the pattern on lowering the resistance of these new membranes. This insight gives us a design tool to continue to innovate and create new patterns for further improvements along with changing the intrinsic chemistry of the material."

In the future, the research group would pursue optimizing the membranes’ chemistry and geometry, and would also learn about printing new materials, for both membranes and beyond, that have not been printed till date.

We want to bridge the fundamental chemistry and materials science that we do with the engineering and rapid design iterations that the 3D printing industry is really good at.

Michael Hickner

Apart from Hickner and Seo, Douglas Kushner, Ph.D. student in materials science and engineering, contributed to the research paper, entitled "3D Printing of Micro-patterned Anion Exchange Membranes."

Penn State Department of Materials Science and Engineering funded for the photolithography system. Infrastructure support was provided by the Materials Research Institute and the Penn State Institutes of Energy and the Environment.