Aug 9 2016

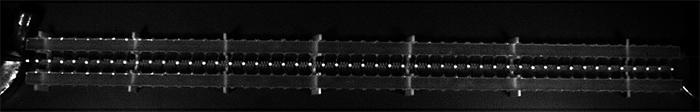

Bistable beams -- structures stable in two distinct state -- store and release elastic energy along the path of a wave. (CREDIT: Bertoldi Lab/Harvard SEAS)

Bistable beams -- structures stable in two distinct state -- store and release elastic energy along the path of a wave. (CREDIT: Bertoldi Lab/Harvard SEAS)

Soft materials possess significant amounts of damping energy, and this is the reason why rubber tires are capable of absorbing the shock of potholes and bumps. If researchers try to develop autonomous soft systems such as soft robots, they will then require a technique to transfer energy across soft materials.

Recently, researchers at the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS), in association with researchers at the California Institute of Technology have come up with a new technique to pass mechanical signals through soft materials.

This study is described in the Proceedings of the National Academy of Sciences.

Soft autonomous systems have received a lot of attention because, just like the human body or other biological systems, they can be adaptive and perform delicate movements. However, the highly dissipative nature of soft materials limits or altogether prevents certain functions. By storing energy in the architecture itself we can make up for the energy losses due to dissipation, allowing the propagation of mechanical signals across long distances.

Jordan Raney, Postdoctoral Fellow, SEAS

Researchers use the age-old concept of bistable beams, referring to structures capable of being stable in two definite states, in order to store and dissipate elastic energy along the path of a wave. The system comprises of a series of bistable elastomeric beams that are connected by elastomeric linear springs.

Deformation of beams results in them snapping and storing energy as elastic deformations. When the signal travels down the elastomer, it snaps the beams back to their original position, releases the stored energy, and sends the signal downstream like a series of dominos. The bistable system arrests the signal from dissipating downstream.

This design solves two fundamental problems in transmitting information through materials. It not only overcomes dissipation, but it also eliminates dispersive effects, so that the signal propagates without distortion. As such, we maintain signal strength and clarity from start to end.

Katia Bertoldi, Associate Professor, SEAS

Precise fabrication techniques are required for beam geometry. The whole system will fail if the thickness or angle of a beam is deviated by one millimeter or one degree.

Advanced 3D printing techniques were used by the team of researchers to fabricate the system.

"We're developing new materials and printing methods that enable the fabrication of soft materials with programmable bistable elements," said Jennifer A. Lewis, who is a Hansjorg Wyss Professor of Biologically Inspired Engineering and coauthor of the paper.

A soft logic gate was designed and printed by the researchers using this system. The gate looks like a tuning fork, and can be directed to act as an AND gate, as well as an OR gate.

It’s amazing what you can do using simple beams - a building block that’s been around hundreds of years. You can do new stuff with a very old, well studied and very simple component.

Katia Bertoldi, Associate Professor, SEAS

The National Science Foundation and the Harvard University Materials Research Science and Engineering Center (MRSEC) supported this study.