Aug 10 2016

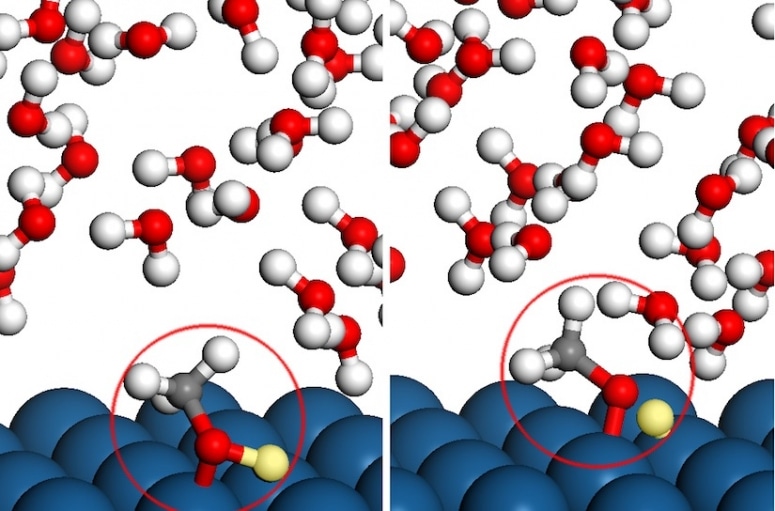

Modeling how methanol interacts with platinum catalysts inside fuel cells in realistic environments becomes even more complicated because distances between the atoms can change as molecules dance near the charged surface. IMAGE COURTESY OF MANOS MAVRIKAKIS

Modeling how methanol interacts with platinum catalysts inside fuel cells in realistic environments becomes even more complicated because distances between the atoms can change as molecules dance near the charged surface. IMAGE COURTESY OF MANOS MAVRIKAKIS

Chemical engineers from the University of Wisconsin–Madison have used a unique blend of enhanced computational methods to demystify some of the difficult catalytic chemistry in fuel cells. This progress will help to bring cost-effective fuel cells much closer to reality.

Understanding reaction mechanisms is the first step toward eventually replacing expensive platinum in fuel cells with a cheaper material.

Manos Mavrikakis, Professor of Chemical and Biological Engineering, UW-Madison

Mavrikakis and colleagues at Osaka University in Japan presented details about the study in the Aug 8, 2016, issue of the journal Proceedings of the National Academy of Sciences.

Fuel cells produce electricity by integrating electrons and protons with oxygen from the air. This combination is carried out with a chemical fuel such as methanol. Fuel cells generally contain catalysts in order to speed up the reaction that generates protons. They will be able to provide power in an efficient manner with the help of an appropriate catalyst together with sufficient air and fuel.

Fuel cells could eventually make laptop batteries obsolete. Almost 20 hours of continuous power can be provided by tablespoons of methanol. However, alternatives to the costly platinum catalyst in the existing fuel cells are yet to emerge as scientists have still not completely understood the complex chemistry required to generate electrons and protons from fuels. Identifying a good catalyst is no trivial task.

“People arrived at using platinum for a catalyst largely by trial and error, without understanding how the reaction takes place,” says Mavrikakis. “Our efforts developed a big picture of how the reaction is happening, and we hope to do the same analysis with other materials to help find a cheaper alternative.”

The chemistry sounds straightforward at the very first glance: Methanol molecules soaked in a watery milieu settle on a platinum surface and give away one of their four hydrogen atoms. An electric current is produced by the movement of those electrons from that hydrogen atom. The scenario is actually not so simple in real terms.

All of these molecules, the water and the methanol, are actually dancing around the surface of the catalyst and fluctuating continuously. Following the dynamics of these fluctuating motions all the time, and in the presence of an externally applied electric potential, is really very complicated.

Manos Mavrikakis, Professor of Chemical and Biological Engineering, UW-Madison

The water molecules are not wallflowers resting on the sidelines of the methanol molecules and reacting with platinum, instead they are cut in to the chemical dance occasionally. The reaction’s tempo is even more interrupted by the changing voltage on the electrified surface of the platinum catalyst.

Earlier, chemists only simulated simplified situations - catalytic surfaces that did not crackle with electricity, or fuel cells without any water in the mix. The results based on these oversimplifications failed to completely capture the immense complexity of real-world reactions.

Mavrikakis and colleagues integrated their expertise in two strong computational methods in order to develop a more accurate description of an extremely complex real environment.

Density functional theory was initially used to solve for quantum mechanical forces and energies between individual atoms. The team then developed a scheme upon those results molecular dynamics techniques to simulate bigger ensembles of water and methanol molecules interacting with the platinum surface and also among themselves.

The in depth simulations pointed out that the existence of water in a fuel cell plays a vital role in deciding which hydrogen atom breaks free from methanol first. This is a result that could not have been captured by simpler methods. Electric charge also revealed the order in which the methanol disintegrates, surprisingly switching the ideal first step at the positive electrode.

With this detail scientist will be able to predict which byproducts might mount up in a reaction mixture, and they will also be able to select improved ingredients for future fuel cells.

Modeling enables you to come up with an informed materials design. We plan to investigate alternative fuels, and a range of promising and cheaper catalytic materials.

Manos Mavrikakis, Professor of Chemical and Biological Engineering, UW-Madison

The results characterize the culmination of six years of effort across two continents. Jeffrey Herron, the first author on the paper, started creating the methodologies during a summer visit to work under the paper’s second author, Professor Yoshitada Morikawa in the Division of Precision Science & Technology and Applied Physics at Osaka University.

Herron, who completed his doctorate in 2015 and is currently a senior engineer for The Dow Chemical Company, further developed these approaches under Mavrikakis’ guidance over several subsequent years in Madison.

“A lot of work over many years went into this paper,” says Mavrikakis. “The world needs fuel cells, but without understanding how the reaction takes place, there is no rational way to improve.”