Sep 13 2016

Fuel cells have long held promise as power sources, but low efficiency has created obstacles to realizing that promise. Researchers at the University of Illinois and collaborators have identified the active form of an iron-containing catalyst for the trickiest part of the process: reducing oxygen gas, which has two oxygen atoms, so that it can break apart and combine with ionized hydrogen to make water. The finding could help researchers refine better catalysts, making fuel cells a more energy- and cost-efficient option for powering vehicles and other applications.

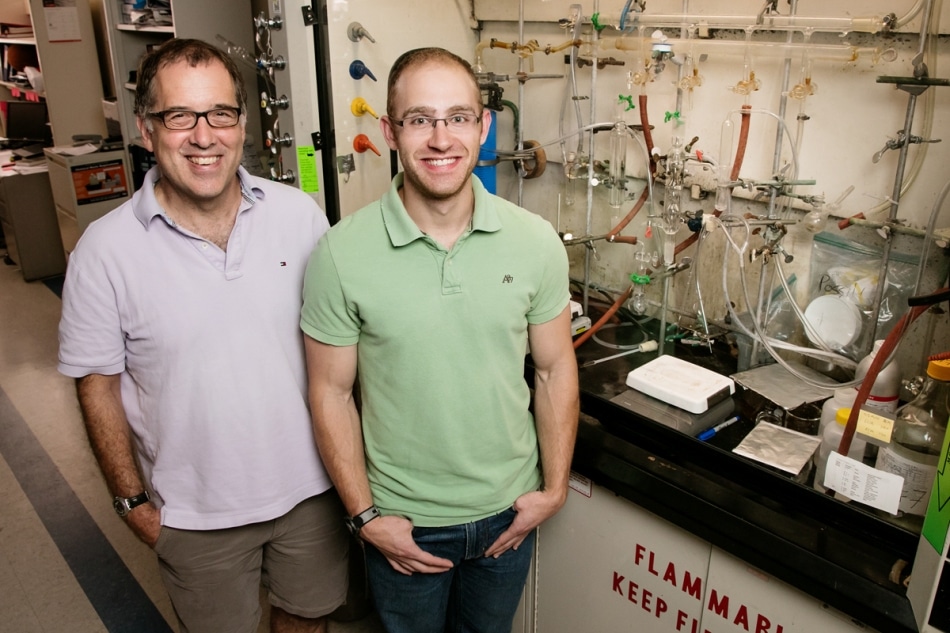

Illinois professor Andrew Gerwith and graduate student Jason Varnell developed a method to isolate active catalyst nanoparticles from a mixture of iron-containing compounds, a finding that could help researchers refine the catalyst to make fuel cells more active. Credit: Photo by L. Brian Stauffer

Illinois professor Andrew Gerwith and graduate student Jason Varnell developed a method to isolate active catalyst nanoparticles from a mixture of iron-containing compounds, a finding that could help researchers refine the catalyst to make fuel cells more active. Credit: Photo by L. Brian Stauffer

Led by U. of I. chemistry professor Andrew Gewirth, the researchers published their work in the journal Nature Communications.

Iron-based catalysts for oxygen reduction are an abundant, inexpensive alternative to catalysts containing precious metals, which are expensive and can degrade. However, the process for making iron-containing catalysts yields a mixture of different compounds containing iron, nitrogen and carbon. Since the various compounds are difficult to separate, exactly which form or forms behave as the active catalyst has remained a mystery to researchers. This has made it difficult to refine or improve the catalyst.

“Previously, we didn’t know what these catalysts were made of because they had a lot of different things inside them,” Gewirth said. “Now we’ve narrowed it down to one component. Since we know what it looks like, we can change it and work to make it better.”

The researchers used a chlorine gas treatment to selectively remove from the mixture particles that were not active for oxygen reduction, refining the mixture until one type of particle remained: a carbon-encapsulated iron nanoparticle.

“We were left with only nanoparticles encapsulated within a carbon support, and that allows them to be more stable,” said Jason Varnell, a graduate student and the first author of the paper. “Iron oxidizes and corrodes on its own. You need to have the carbon around it in order to make it stable under fuel cell conditions.”

The researchers hope that narrowing down the active form of the catalyst can open new possibilities for making purer forms of the active catalyst, or for tweaking the composition to make it even more active.

“What’s the optimal size? What’s the optimal density? What’s the optimal coating material? These are questions we can now address,” Gewirth said. “We’re trying alternative methods for synthesizing the active catalyst and making multicomponent nanoparticles with certain amounts of different metals. Previously, people would add some metal salt into the tube furnace, like cooking – a little of this, a little of that. But now we know we also need to do things at different temperatures to put other metals in it. It gives us the ability to make it a more active catalyst.”

Ultimately, the researchers hope that improved catalyst function and manufacturability will lead to more-efficient fuel cells, which could make them useful for vehicles or other power-intensive applications.

“Now we understand the reactivity better,” Varnell said. “This could lead to the creation of more viable alternatives to precious metal catalysts.”

The National Science Foundation supported this work.