Nov 17 2016

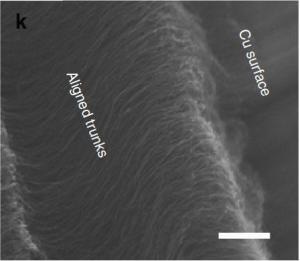

A side view provided by a scanning electron microscope shows that the structural integrity of the carbon nanotube adhesive holds up after exposure to 1033 degrees Celsius (Credit: Courtesy of Science Communications)

A side view provided by a scanning electron microscope shows that the structural integrity of the carbon nanotube adhesive holds up after exposure to 1033 degrees Celsius (Credit: Courtesy of Science Communications)

Scientists have developed a new dry adhesive that bonds in extreme temperatures, a quality that could make this product suitable for space exploration and beyond. The adhesive was developed by researchers from Case Western Reserve University, Dayton Air Force Research Laboratory, and China.

According to the researchers, the gecko-inspired adhesive does not lose traction in temperatures as hot as molten silver or as cold as liquid nitrogen. In fact, as the heat increases, the adhesive becomes stickier.

The results of the study have been reported in the Nature Communications journal. The study builds on a previous research work where a dry, single-sided adhesive tape based on vertically aligned carbon nanotubes (CNTs) was developed. The team claims that no other dry adhesive can work at such extreme temperatures.

Liming Dai, author of the study and professor of macromolecular science and engineering at Case Western Reserve, partnered with Feng Du, senior research associate in Case Western Reserve’s Department of Macromolecular Science and Engineering; Ming Xu, a senior research associate at Case School of Engineering and visiting scholar from Huazhong University of Science and Technology; and Ajit Roy and Sabyasachi Ganguli of the Materials and Manufacturing Directorate, Air Force Research Laboratory.

The researchers said that vertically aligned CNTs, with tops bundled into nodes, replicate the tiny hairs on the foot of gecko - the wall-walking reptile - and continue to remain stable from -320°F to 1,832°F.

When you have aligned nanotubes with bundled tops penetrating into the cavities of the surface, you generate sufficient van der Waal’s forces to hold. The dry adhesive doesn’t lose adhesion as it cools because the surface doesn’t change. But when you heat the surface, the the surface becomes rougher, physically locking the nanotubes in place, leading to stronger adhesion as temperatures increase.

Ming Xu, Senior Research Associate, Case Western Reserve University

As the adhesive remains stable across a wide temperature range, it is suitable for space, where the shade can be cold and exposed to the sun blazing hot. In addition to the temperature range, the adhesive includes properties that could further increase its value. The bonding agent can conduct electricity and heat, and these properties increase with increased temperature.

“When applied as a double-sided sticky tape, the adhesive can be used to link electrical components together and also for electrical and thermal management,” Roy said.

This adhesive can thus be used as connecting materials to enhance the performance of electronics at high temperatures. At room temperature, the double-sided carbon nanotube tape held as strongly as commercial tape on various rough surfaces, including paper, wood, plastic films and painted walls, showing potential use as conducting adhesives in home appliances and wall-climbing robots.

Liming Dai, Professor, Case Western Reserve University

Holding Strength

During a test, when a double-sided tape based on CNTs was applied between two layers of copper foil, it had an adhesive strength of approximately 37 N/cm-2 at room temperature, which was roughly the same as a commercially available double-sided sticky tape.

The CNT adhesive was able to maintain its strength down to -320°F, unlike the commercial double-sided sticky tape, which tends to lose adhesion on heating or freezing. At 785°F, the adhesive’s strength more than doubled and at 1891°F, it was approximately six times as strong.

The researchers were surprised by the increasing strength of the adhesive and eventually used a scanning electron microscope to explore the reason. They discovered that as the bundled nodes enter the surface cavities, the flexible CNTs collapse into web-like structures and no longer remain vertically aligned. This action seems to improve the van der Waal’s forces as a result of an increased contact surface area with the collapsed CNTs.

Looking beyond, the team observed that when the temperature reached more than 392°F, the surface of the copper foil became gradually rougher. The collapsed CNTs and the bundled ends seem to enter deeper into the heat-induced irregularities of the surface cavities, increasing adhesion. This adhesion mechanism has been dubbed as “nano-interlocking” by the researchers.

The adhesive continued to remain strong during innumerable temperature transition cycles between -320°F and ambient temperature then up to 1891°F and between the ambient temperature and extreme cold.

Although copper foil was applied in many of the tests used to show the capacity for thermal management, it is not unique. The surface of polymer films, other metal foils, and many similar materials become rough on applying heat. This makes them suitable targets for this type of adhesive, suggest the researchers.

The National Science Foundation and the Department of Defense Air Force Office of Scientific Research Multidisciplinary Research Program of the University Research Initiative supported the study.