Dec 19 2016

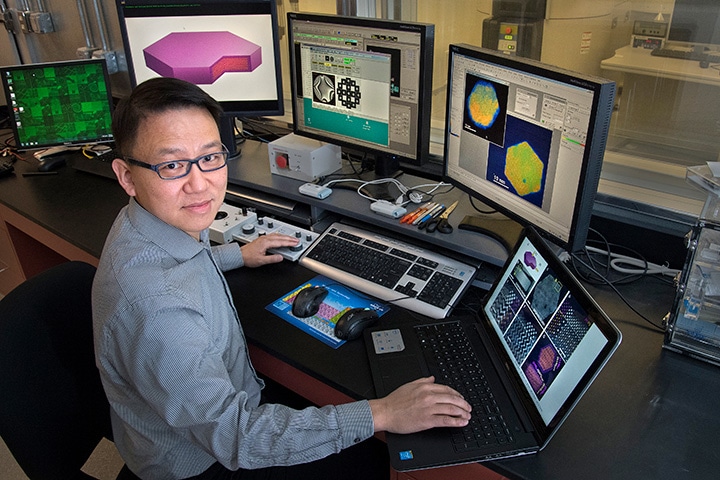

Dong Su in the control room of the aberration-corrected scanning transmission electron microscope (Hitachi HD2700C) at the Center for Functional Nanomaterials, a U.S. Department of Energy Office of Science User Facility at Brookhaven Lab. On the computer screens are images of the platinum-based nanoplates that Su and his collaborators developed. The nanoplates have a thick, ordered shell of platinum that surrounds a platinum and lead alloyed core. This special structure is thought to be behind the high catalytic activity and stability of the nanoplates. Credit: Brookhaven National Laboratory

Dong Su in the control room of the aberration-corrected scanning transmission electron microscope (Hitachi HD2700C) at the Center for Functional Nanomaterials, a U.S. Department of Energy Office of Science User Facility at Brookhaven Lab. On the computer screens are images of the platinum-based nanoplates that Su and his collaborators developed. The nanoplates have a thick, ordered shell of platinum that surrounds a platinum and lead alloyed core. This special structure is thought to be behind the high catalytic activity and stability of the nanoplates. Credit: Brookhaven National Laboratory

Despite being a promising technology for generating electrical power in an efficient and clean way, the main challenges in the commercialization of fuel cells are activity, cost, and durability. Costly platinum (Pt)-based nanoparticles are used as catalysts in new generation fuel cells to speed up the reactions that cause conversion of chemical energy from renewable fuels (e.g. ethanol, methanol, and hydrogen) into electrical energy.

Reduction in cost and enhancement in activity and durability can be achieved by using catalysts that include less expensive metals inside the nanoparticles. However, before using these fuel cells in generators, vehicles, and other applications, it is required to further enhance these catalysts.

Currently, researchers at the U.S. Department of Energy’s (DOE) Brookhaven National Laboratory, Shanghai Institute of Applied Physics, Soochow University, California State University–Northridge, and Peking University have developed catalysts with the ability to undergo 50,000 voltage cycles with no apparent changes in their elemental composition or structure and at a negligible decay in their catalytic activity.

A paper published in the Science journal, in the December 16 issue, describes the catalysts to be “nanoplates” having atomically ordered Pt and lead (Pb) core, where a thick uniform shell of four Pt layers surrounds the core.

Until now, catalysts with a Pt-based core-shell structure were the most successful catalysts in terms of boosting the activity of oxygen reduction reaction (ORR), which is a very slow reaction that considerably limits the efficiency of fuel cells.

Yet, these catalysts normally possess a thin and incomplete shell because of their difficult synthesis. Over a long period of time, such a shell permits leaching of the acid from the fuel cell environment into the core, where the acid reacts with the other metals, causing a short catalyst lifetime and poor long-term stability.

The goal is to make the ORR as fast as possible with catalysts that have the least amount of platinum and the most stable operation over time. Our PtPb/Pt catalysts show high ORR activity and stability - two parameters that are key to enabling a hydrogen economy - placing them among the most efficient and stable bimetallic catalysts reported for ORR.

Dong Su, Scientist at Brookhaven Lab’s Center for Functional Nanomaterials (CFN)

Lattice strain for enhanced catalytic performance

In earlier studies, researchers have demonstrated that ORR activity in core-shell catalysts can be optimally improved by compressing the Pt atoms on one particular lattice surface plane called Pt(111). Such a compressive strain is generated when metals smaller in size than Pt (e.g. nickel) are added to the shell’s core, and weakens the binding of oxygen to the Pt surface at which the catalytic reaction occurs.

The ideal ORR catalyst needs to help break bonds (between oxygen molecules) and form bonds (between oxygen and hydrogen), so oxygen can’t be too strongly or too weakly bound to the platinum surface. Scientists have focused their research on the compressively strained Pt(111) surfaces, in which Pt atoms are squeezed across the surface, because the oxygen binding energy is optimized. In general, scientists thought that tensile strain on the same surface plane would result in overly strong binding of oxygen and thus hinder the ORR reaction.

Dong Su, Scientist at Brookhaven Lab’s Center for Functional Nanomaterials (CFN)

However, Su and his colleagues demonstrated that ORR catalytic activity can also be enhanced by introducing a large tensile strain along one direction of a different surface plane, i.e. Pt(110). They added Pb—larger than Pt—to the Pt shell core, thus making the Pt atoms to stretch across the surface.

Nanoplate characterization and durability testing

Once the research group headed by Xiaoqing Huang - corresponding author from Soochow University - produced the nanoplates, structure and elemental composition at the CFN were characterized by Su. He confirmed the composition and sequence of the atoms as well as the core-shell structure by using electron diffraction patterns and images from high-resolution scanning transmission electron microscopy (STEM).

Both the techniques reveal the relative positions of atoms. For the purpose of confirming that the shell contained Pt and that the core contained Pt and Pb, Su measured the change in the electrons’ energy after their interaction with the nanoplates, also known as electron energy-loss spectroscopy.

The research team used this information to distinguish the way in which the nanoplates are formed with the individual Pb and Pt atoms. Surprisingly, they found the surface planes were Pt(110), and not Pt(111), and the Pt(110) planes were under biaxial strain (i.e. tensile strain in one direction and compressive strain in the other) originating from the PtPb core.

While carrying out durability tests that simulated fuel cell voltage cycling, Su and his colleagues discovered that there was nearly no change in the amount of generated electrical current after 50,000 cycles. That is, there was a minimal decay in the catalytic activity of the nanoplates. Most catalysts exhibit some activity loss after these many cycles, with some catalysts losing even more than half of their actual activity.

There was no change in the elemental composition and structure of the nanoplates did not change upon durability testing using synchrotron characterization and microscopy techniques. “The electron microscopy work at CFN was critical in explaining why our nanoplates showed such high catalytic activity and stability,” stated Huang.

Considering the amount of Pt used, when compared with commercial Pt-on-carbon (Pt/C) catalysts, the PtPb/Pt nanoplates synthesized by the research team possess the highest ORR activities till date, as well as exceptional durability. The nanoplates synthesized by the team also exhibited high electrocatalytic activity and stability during oxidation reactions of ethanol and methanol.

“We believe the relatively thick and complete Pt layers play an important role in protecting the core,” stated Su.

For better perception of the origin of the high ORR activity in the nanoplates, the scientists computed the binding energy between Pt atoms and oxygen atoms on the surface. The computations confirmed that the enhanced ORR activity was due to the tensile strain on the Pt(110) surface.

This work opens up a new way to introduce large tensile strain on the stable Pt(110) plane to achieve very high activity for oxygen reduction catalysis. We believe that our approach will inspire efforts to design new nanostructured catalysts with large tensile strain for more efficient catalysis.

Shaojun Guo from Peking University

In the due course, tests on the laboratory-level electrocatalysts should be carried out by using them in a larger fuel cell system in which real-world variables (e.g. pollutants probably affecting surface reactivity) can be introduced.

Apart from the electron microscopy investigations carried out at CFN (which was supported by DOE’s Office of Science) this study also involved synchrotron characterization by Jing-Yuan Ma at Shanghai Synchrotron Radiation Facility as well as theoretical computations by Gang Lu’s team at California State University–Northridge. This research was further supported by the National Basic Research Program of China, the Ministry of Science and Technology of the People’s Republic of China, the National Natural Science Foundation of China, Soochow University, the Young Thousand Talents Program, Peking University, the U.S. Army Research Office, and the Priority Academic Program Development of Jiangsu Higher Education Institutions.