Dec 21 2016

Researchers from Universidad Politécnica have developed an innovative procedure that may significantly improve the therapeutic capacity of implants.

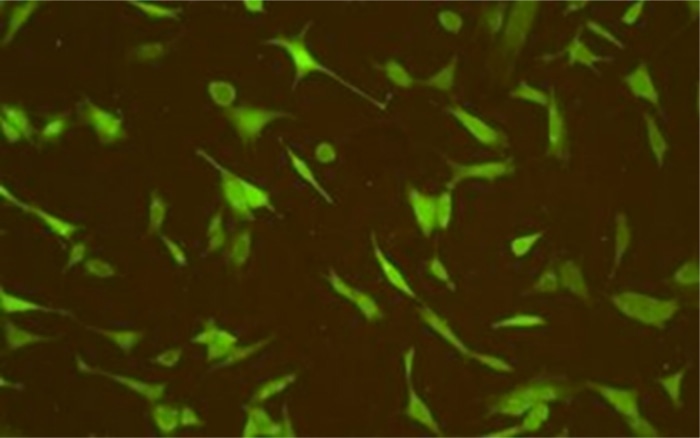

Developing cells on a biofunctional layer. (Credit: UPM)

Developing cells on a biofunctional layer. (Credit: UPM)

A group of researchers from Universidad Politécnica de Madrid (UPM) have developed a new technique to improve the biocompatibility of the materials used for prosthesis. The procedure consists in placing a thin film on such material resulting in a stable bond of a large number of bioactive species. Because of this stable bond, the probability of developing infections decrease as well as the reactions of the organism to these functionalized implants.

We live in a world where we see common to regularly send space probes to explore other planets. We are also used to carry devices in our pockets with a computing capacity higher than the one used to send the first man to the Moon. Because of the speed and depth of these technical advances, it is paradoxical that the therapeutic solutions provided by the materials used in medicine have hardly changed over the last 20 or 30 years.

The main cause of this slow development is not neither the lack of social interest nor an economic issue. The major difficulty lies in the complex interaction between the material and our organism. Such interaction is based on a series of mechanisms that we only know incompletely, however these mechanisms play a determinant role in the processes that occur in the border between the surface of the material and organic tissues. Consequently, the relevance of the surface of the material in the success or failure of the implant is essential when developing techniques addressed to improve the biocompatibility of materials.

Among the procedures developed to modify the surface of materials and improve the reaction of the organisms to these materials, researchers stand out those materials able to create a stable bond between the surface and bioactive elements such as proteins. This family of procedures is given the generic name of functionalization techniques (also biofunctionalization). Most of the functionalization techniques are based on the chemical reaction of the material with a suitable precursor. The reactions are usually relatively simple, but they have the disadvantage that they are very dependant of the composition of the material.

In order to overcome this difficulty, a group of UPM researchers has developed a procedure of versatile and strong functionalization by which a functional thin film of a thickness less than one thousandth of a millimeter is placed on the material used in the implant. The technique, called Activated Vapor Silanization (AVS), can be virtually used with all metallic and ceramic biomaterials, and the functional layer is sufficiently versatile to permit the stable bond of a large number of bioactive species.

The researchers responsible for this work say: “the application of this procedure is a new approach of excellent expectations to improve the reaction of the organism to implants, since it allows us to provide the functionalized implants with new properties. Among others, we highlight the possibility to decrease de probability to develop an infection as a consequence of the implant, or to improve the stability of bond of the material to the surrounding tissue.

Additionally, the versatility of the procedure in terms of both the composition of the materials and geometry of the prosthesis make feasible its adaptation with minimum changes to the procedures of fabrication of the biomaterials used today. For this reason, it is foreseeable that the application of the functionalized biomaterials will be a therapeutic alternative in a near future.

Rezvanian, P.; Arroyo-Hernandez, M.; Ramos, M.; Daza, R.; Elices, M.; Guinea, G.V.; Perez-Rigueiro, J. Development of a versatile procedure for the biofunctionalization of Ti-6Al-4V implants. Applied Surface Science 387. Pages: 652-60. DOI: 10.1016/j.apsusc.2016.06.139. Nov. 2016.