Mar 13 2017

Researchers of Peter the Great St. Petersburg Polytechnic University and Delft University of Technology obtained a gradient microstructure of the material and created a product, combining properties of two metals. (Credit - Peter the Great St. Petersburg Polytechnic University)

Researchers of Peter the Great St. Petersburg Polytechnic University and Delft University of Technology obtained a gradient microstructure of the material and created a product, combining properties of two metals. (Credit - Peter the Great St. Petersburg Polytechnic University)

Researchers from Peter the Great St. Petersburg Polytechnic University (SPbPU) and Delft University of Technology have developed a technology for acquiring new metal structures using a selective laser melting technique (additive technology of producing 3D objects from metal powders).

The key research findings have been illustrated in an article "Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties" published in Materials & Design journal.

This technology allows acquiring the material’s gradient microstructure and creating a product, by integrating the properties of two metals. This material is characterized by high performance features, such as pressure and temperature effects, durability, and strength.

This technology can be used for manufacturing of products operating in extreme conditions, such as high pressure and temperature. Therefore, this development can be applied for manufacturing of gas turbines elements for aviation, energy and marine.

Vadim Sufiiarov, Assistant Professor, SPbPU

Commonly, selective laser melting may be employed to construct a fine-grained microstructure of the metal, which offers high mechanical properties at room temperature. However, the gases at the gas turbine engine’s combustion chamber exit have the highest pressure and temperature. The gases forcefully act on the elements of the hot part of the turbine, mainly on vanes and blades, which are in charge of the rotor mechanism.

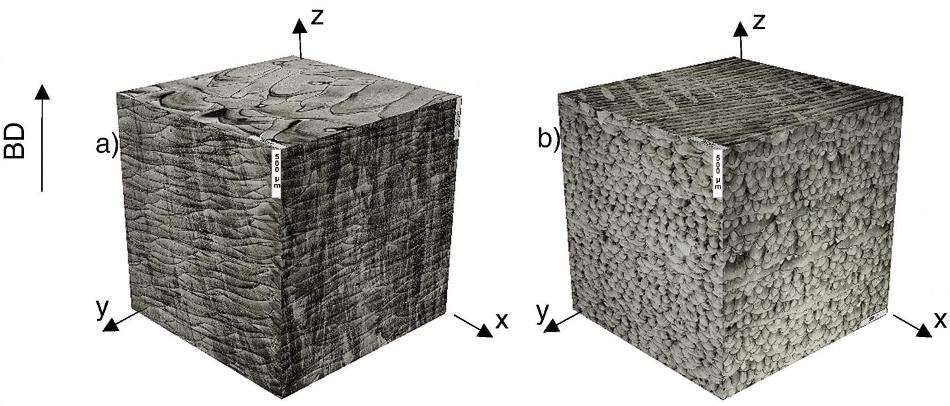

The first and second stage blades have the maximum load, so they are not just produced using particularly designed high-temperature alloys, but also form a special microstructure in the product. It is either single-crystal (when the product is composed of one grain and one crystal type) or directionally crystallized (without grain boundaries in the transverse direction, grain boundaries found only along longitudinal direction).

Using this technology, both equiaxial structures can be created, where the grains have around the same dimensions in all directions, as well as directionally crystallized grains and merge their arrangement in one product. Developed approach of additive technologies allows versatile manipulation of material microstructure formation.