Mar 13 2017

Researchers and professors at McGill University in Canada have worked with 3D printing a number of times, using the technology to 3D print better hip replacements, and even more absurd-sounding items, like building a 3D printed tiger out of ice and a 3D printed statue of Canada’s 7th Prime Minister out of polyurethane foam and shaving cream. Recently, a research team with the university’s Department of Mechanical Engineering used modeling, optimization, and 3D printing to develop bio-inspired interlocking sutures.

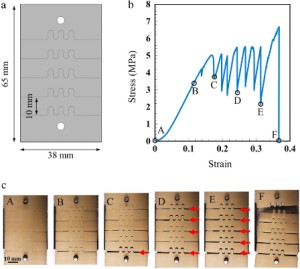

A bistable interlocked material (BIM); (a) Geometry of the tensile test sample with multiple interlocked sutures; (b) A typical tensile stress–strain curve (here with θ 1 = 15° and R 1 /R 2 = 1.05) showing a plateau-like region corresponding to the transformation of the sutures. (c) In-situ images showing different stages of loading and progressive transformation of tabs to their second stable configuration. All the potential sites have transitioned to the second stable position (stage E) prior to complete failure (stage F). (Credit: ResearchGate)

A bistable interlocked material (BIM); (a) Geometry of the tensile test sample with multiple interlocked sutures; (b) A typical tensile stress–strain curve (here with θ 1 = 15° and R 1 /R 2 = 1.05) showing a plateau-like region corresponding to the transformation of the sutures. (c) In-situ images showing different stages of loading and progressive transformation of tabs to their second stable configuration. All the potential sites have transitioned to the second stable position (stage E) prior to complete failure (stage F). (Credit: ResearchGate)

Associate Professor Francois Barthelat, who works with 3D printing, experimental mechanics, and natural materials every day in his Laboratory for Advanced Materials and Bioinspiration, led the team. In the lab, he and his students work to characterize the mechanics, structure, and multi-functionalities of natural materials, as well as design, fabricate, and test unique, high-performance engineering systems and materials that are inspired by nature; their current models include fish scales, mollusk shells, bone, and collagen, among others. His team’s research was published in a paper titled “Bio-inspired ‘Jigsaw’-like sutures: Modeling, optimization, 3D printing and testing,” in the Journal of the Mechanics and Physics of Solids; listed co-authors are postdoctoral researcher Mohammad Mirkhalaf and PhD candidate Idris Malik.

According to the paper’s abstract, “Structural biological materials such as bone, teeth or mollusk shells draw their remarkable performance from a sophisticated interplay of architectures and weak interfaces. Pushed to the extreme, this concept leads to sutured materials, which contain thin lines with complex geometries. Sutured materials are prominent in nature, and have recently served as bioinspiration for toughened ceramics and glasses. Sutures can generate large deformations, toughness and damping in otherwise all brittle systems and materials. In this study we examine the design and optimization of sutures with a jigsaw puzzle-like geometry, focusing on the non linear traction behavior generated by the frictional pullout of the jigsaw tabs. We present analytical models which accurately predict the entire pullout response.”

Geometric interlocking is very important in the adhesion and cohesion of both structures and materials; examples include fiber-reinforced composites, engineering, and adhesive science. This phenomenon is definitely present in nature, and is critical in tough biological materials, like bone, because it actually generates “toughness” and dissipates energy in materials that are normally brittle. Architectured materials based on this kind of bio-inspired interlocking have recently presented some attractive and unique combinations of properties; in the McGill study, the team introduced a new type of sutured material that combines architecture, bioinspiration, and geometric interlocking, while also exploring the sutures’ multi-stability, involving sliding and interlocking between two distinct, stable states.

Using a non-Hertzian contact solution problem, the researchers worked out a solution to determine the maximum stress and pullout response in the interlocking materials; geometrical parameter and friction coefficient are used to tune the material response, and they learned that as the coefficient and interlocking angle increase, so too does the material’s resistance to pull out of the suture interface. In order to verify this pullout response, the researchers used mechanical testing and 3D printing, which ultimately showed that in order to optimize the stiffness, energy absorption, and maximum strength of the materials, it’s better to use a lower friction coefficient, with a higher locking angle.

3D printed samples were used to investigate the performance of different combinations of the interlocked sutures. A high-resolution DLP 3D printer from EnvisionTEC was used to print homogeneous, pore-free, and mechanically isotropic components, using a UV-curable ABS material. The high resolution of the 3D printer was especially helpful in producing smooth materials, an important factor in lowering the stress concentration and keeping the friction coefficient consistent. The two solid parts that make up the interlocked tab were 3D printed individually, and then slid together. All six parts of the sample were constructed this way, by being 3D printed in separate parts and then manually assembled.

The abstract concluded, “The models and guidelines we present here can be extended to other types of geometries and sutured materials subjected to other loading/boundary conditions. The nonlinear response of sutures are particularly attractive to augment the properties and functionalities of inherently brittle materials such as ceramics and glasses.”

The research team determined that mechanisms typically associated with geometric interlocking and sutures, which are commonplace in natural structured materials, have a high engineering potential, which has not yet been fully exploited. Discuss in the Interlocking Sutures forum at 3DPB.com.