Apr 5 2017

Credit: North Carolina State University

Credit: North Carolina State University

A team of researchers from North Carolina State University have developed elastic, touch-sensitive fibers with the capability of interfacing with electronic devices.

Touch is a common way to interact with electronics using keyboards and touch screens. We have created soft and stretchable fibers that can detect touch, as well as strain and twisting. These microscopic fibers may be useful for integrating electronics in new places, including wearable devices.

Michael Dickey, Professor of Chemical and Biomolecular Engineering, NC State

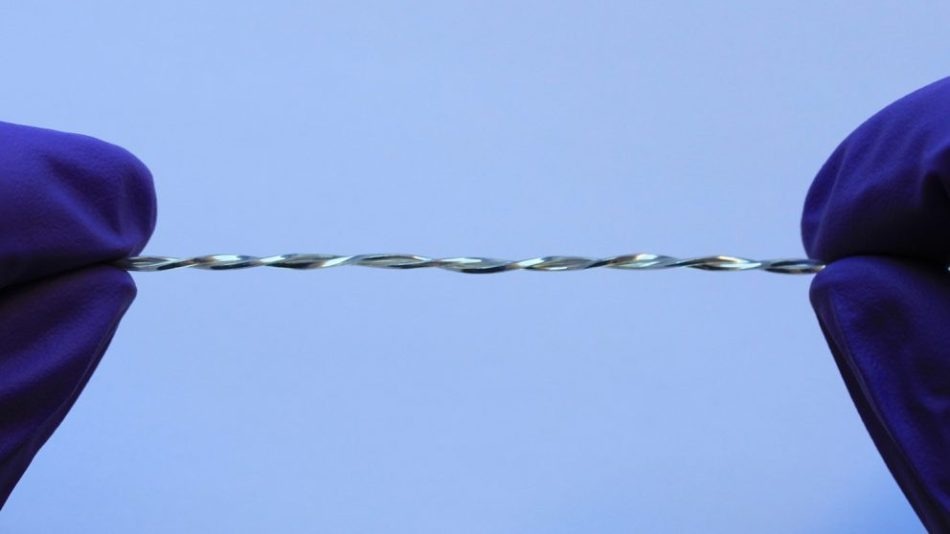

The new fibers are composed of tube-like polymer strands that have a liquid metal alloy, eutectic gallium and indium (EGaIn). The strands measure just a few hundred microns in diameter, which is marginally thicker than a human hair.

Each fiber comprises of three strands. One strand is fully filled with EGaIn, one is two-thirds filled with EGaIn, and one is only one-third filled with EGaIn. Then the slim tubes are twisted together to form a tight spiral.

The touch-responsive fiber functions due to capacitance, or the phenomenon in which electric charge is stored between two conductors divided by an insulator.

For instance, when the finger (which is a conductor) touches the screen of a smartphone (which is an insulator), it changes the capacitance between the finger and the electronic material beneath the screen. The technology in the smartphone then interprets that alteration in capacitance as a command to type on the keypad or to open an app.

Likewise, when the finger touches the elastic fiber, it transforms the capacitance between your finger and the EGaIn within the insulating polymer strands.

By moving the finger along the fiber, the capacitance will change, based on how many of the strands have EGaIn at that point in the fiber. This effectively offers users the ability to transmit a variety of electronic signals depending on which part of the fiber they touch.

Wearable Touch Sensors: Stretchable Conductive Fibers

The researchers also built a sensor using two polymer strands, both of which are fully filled with EGaIn.

Once more, the strands are twisted into a tight spiral. When the number of twists is increased, it elongates the elastic strands and causes the EGaIn in the two tubes to come closer together. This alters the capacitance between the two strands.

We can tell how many times the fiber has been twisted based on the change in capacitance. That’s valuable for use in torsion sensors, which measure how many times, and how quickly, something revolves. The advantage of our sensor is that it is built from elastic materials and can therefore be twisted 100 times more – two orders of magnitude – than existing torsion sensors.

Michael Dickey, Professor of Chemical and Biomolecular Engineering, NC State

The research paper, “Stretchable Capacitive Sensors of Torsion, Strain, and Touch Using Double Helix Liquid Metal Fibers,” is published in the Advanced Functional Materials journal. Lead author of the paper is Christopher Cooper, an undergraduate at NC State. The paper was co-authored by Kuralamudhan Arutselvan, Daniel Armstrong, Yiliang Lin, and Mohammad Rashed Khan, who are Ph.D. students at NC State; by Ying Liu, a postdoctoral researcher at NC State; and by Jan Genzer, the S. Frank and Doris Culberson Distinguished Professor of Chemical and Biomolecular Engineering at NC State. The work was supported by Army Natick under grant number W911QY-14-C-0033.