Jul 18 2017

It is good to look at Mother Nature for inspiration especially when it comes to efficiency, even for advanced technology such as printable, flexible electronics.

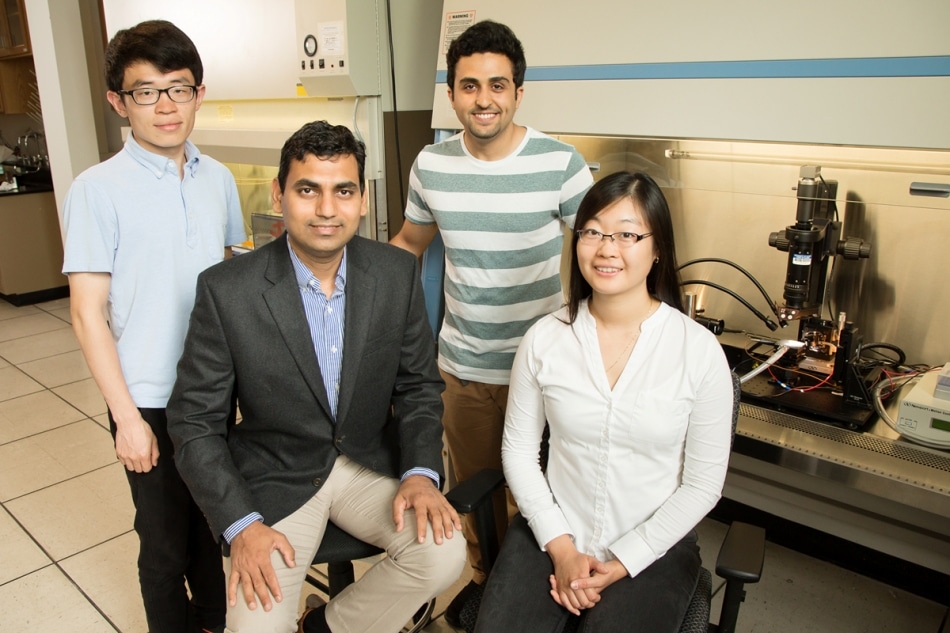

Illinois Researchers have developed a new dynamic template that could be critical to the advancement of printable electronics technology. From bottom right, clockwise: Ying Diao and Diwakar Shukla, Professors of Chemical and Biomolecular Engineering; Chuankai Zhao and Erfan Mohammadi, Graduate Students. (Photo by L. Brian Stauffer)

Illinois Researchers have developed a new dynamic template that could be critical to the advancement of printable electronics technology. From bottom right, clockwise: Ying Diao and Diwakar Shukla, Professors of Chemical and Biomolecular Engineering; Chuankai Zhao and Erfan Mohammadi, Graduate Students. (Photo by L. Brian Stauffer)

A team of Researchers at the University of Illinois have created bio-inspired dynamic templates that can be used to manufacture organic semiconductor materials that produce printable electronics. It uses a process akin to biomineralization – the way that teeth and bones form. This method is also eco-friendly compared with how conventional electronics are built, which gives the Researchers an opportunity to return the favor to nature.

Templating is used for manufacturing near-perfect semiconductors to improve their electronic properties, or to control the spacing between atoms for enhanced electronic properties. These templates help to correctly align the atoms of semiconductor materials, usually germanium or silicon, into the form that is required.

However, this conventional procedure only functions well for rigid nanoelectronic devices. The larger, more chaotic organic polymer molecules required to create flexible electronics cannot align around a fixed template.

In a new report in the Nature Communications journal, Chemical and Biomolecular Engineering Professor Ying Diao, Graduate Student Erfan Mohammadi and Co-Authors explain the functioning of the biomineralization-like method.

In nature, certain biological organisms construct mineralized structures by recruiting or harvesting inorganic ions using flexible biologic polymers. Likewise, the templates Diao’s group formed are composed of ions that reconfigure themselves around the atomic structure of the semiconductor polymers. In this manner, the large polymer molecules can form very ordered, templated structure, Diao said.

This very ordered structure surpasses the quality control issues that have afflicted organic semiconductors, decelerating development of flexible devices.

Our templates allow us to control the assembly of these polymers by encouraging them to arrange on a molecular level. Unlike printing of newspapers, where the ordering of the ink molecules does not matter, it is critical in electronics.

Professor Ying Diao, Chemical and Biomolecular Engineering, University of Illinois

The manufacturing process that can employ these dynamic templates is also eco-friendly. In contrast to conventional semiconductor manufacturing techniques that require temperatures of around 3,000 °F and create a substantial amount of organic waste, this process create minimal waste and can be performed at room temperature, thereby cutting energy costs, Diao said.

Our research looks to nature for solutions. In nature, polymers are used to template ions, and we did the opposite – we use ions to template polymers to produce flexible, lightweight, bio-integrated electronics at low cost and large scale.

Professor Ying Diao, Chemical and Biomolecular Engineering, University of Illinois

Other Co-Authors of this research include Graduate Student Ge Qu and Postdoctoral Scholar Fengjiao Zhang of Chemical and Biomolecular Engineering; Professor Jian-Min Zuo and Graduate Student Yifei Meng of Materials Science and Engineering; and Professor Jianguo Mei and Graduate Student Xikang Zhao of Purdue University.

This research was supported by The U. of I., the National Science Foundation, the United States Department of Energy and the Office of Naval Research Young Investigator Program.