Sep 8 2017

With the advent of additive manufacturing, commonly known as 3D printing, Scientists are limited only by their imagination and the quality of the component that they can create.

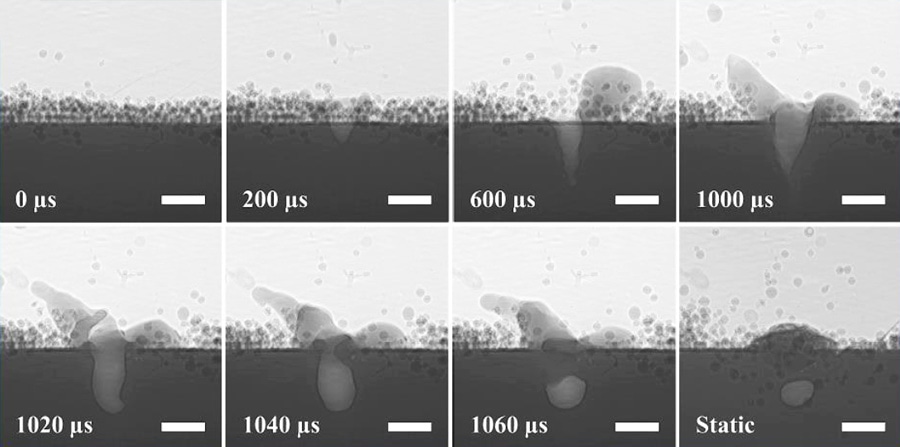

In these high-speed x-ray images, the 3-D printer is using a laser to melt metal powder, which causes a ‘keyhole’ defect within the cooled material. Researchers at Argonne are studying this process and developing guidelines to avoid such errors. (Image by Argonne National Laboratory.)

In these high-speed x-ray images, the 3-D printer is using a laser to melt metal powder, which causes a ‘keyhole’ defect within the cooled material. Researchers at Argonne are studying this process and developing guidelines to avoid such errors. (Image by Argonne National Laboratory.)

By heating metal or plastic powders with lasers, Engineers have already constructed pedestrian bridges, cars and even synthetic jawbones layer by layer. This technology could redefine manufacturing as Engineers use metal alloys, including titanium, to tap raw materials in a much more efficient manner. This, in turn, will shorten supply chains and reduce both weight and product costs.

However, metal additive manufacturing involves certain challenges. Structural defects are often present in printed materials and these materials also differ from their designs. As a result, Engineers are forced to repair their finished pieces or begin all over again from scratch. Also, not all physics behind the process are properly understood and it is trial and error in most of the research performed in this area, which is both a time-consuming and costly way to innovate.

We captured the process at 50,000 frames a second using the high-speed X-ray instrument at the Advanced Photon Source. We can study the resulting movie frame by frame to examine how the material’s microstructure, especially defects and pores, form.

Tao Sun, Argonne Physicist

In order to deal with these issues, a team of Researchers from the U.S. Department of Energy’s (DOE) Argonne National Laboratory, Missouri University of Science and Technology, and Carnegie Mellon University are studying the entire process of 3D printing to discover how defects are formed and the methods available to prevent them. In addition to the 3D printing process, the team is investigating the material properties of the metal powders and the way those powders are melted and shaped by the lasers into the required components.

Now for the first time ever, Researchers recently viewed the inside of 3D printed materials in real-time as the laser melted and molded the metal powders into the desired components. As the laser prints and shapes the metal components, Argonne Physicist Tao Sun and his associates were clearly able to view its inner workings through the powerful synchrotron X-rays at the Advanced Photon Source, a DOE Office of Science User Facility based at Argonne.

“The laser-metal interaction happens very quickly,” said Sun. “Fortunately, we captured the process at 50,000 frames a second using the high-speed X-ray instrument at the Advanced Photon Source. We can study the resulting movie frame by frame to examine how the material’s microstructure, especially defects and pores, form.”

The Researchers demonstrated that they can view and measure many characteristics of metal 3D printing, including powder ejection, melt pool size/shape, solidification, phase transformations and porosity formation.

Sun will share these key conclusions with associates in academia and other national labs who are constructing models to consistently predict the printed materials’ characteristics. The models are also capable of predicting process dynamics, such as the way the laser melts the powder, when the powder transforms into liquids and gases, etc.

In the meantime, Aaron Greco, Project Co-leader for Argonne’s additive manufacturing effort and a principal Materials Scientist at Argonne, improves the models from another angle. “After printing, we examine the product’s resulting microstructure and defects,” said Greco. “We use a variety of techniques including optical and electron microscopy and even tomography at the Advanced Photon Source, to validate the models.”

The outcome is a virtuous loop wherein the experimental data feeds into the additive manufacturing models, and the improved models are subsequently tested by more insightful and elaborate experiments. This interaction between experimentalists and modelers is important to clearly and precisely interpret the underlying materials physics needed to make 3D-printing truly reliable.

While this loop is very important to their crucial understanding of additive manufacturing technology, the researchers’ ambitions go beyond that.

Our goal is to explore new possibilities. Industries are currently limited to a certain set of metal alloys. But what about new ones? If you understand the physical properties related to how to print new alloys, you can adopt these into the process and speed up the reliability of printing.

Aaron Greco, Project Co-leader and a principal Materials Scientist, Argonne

The highly detailed models which are now needed to define the printing process for intricate components also limit the industries considerably. The Researchers believe that if the models are reduced to just the handful of elements that impact reliability and quality, they can be made faster and more appropriate for industries.

Eventually, Argonne’s efforts will accomplish the best of both worlds: Researchers will be able to solve the dynamic mysteries of metal additive manufacturing, whilst industries will flourish with blueprints to quickly print reliable, cost-effective products.

Our work will not only help industries improve efficiency and performance, but increase the likelihood that metal additive manufacturing will be more widely adopted in other applications.

Aaron Greco, Project Co-leader and a principal Materials Scientist, Argonne

Sun’s research was published in the Scientific Reports article titled, “Real-time monitoring of laser powder bed fusion process using high-speed x-ray imaging and diffraction.” The experiments were carried out at the 32-ID-B beamline of Advanced Photon Source.

Argonne News Brief: Cutting-edge science makes 3D printing more efficient and reliable