Nov 16 2017

Excess hydrogen is capable of causing problems in a wide range of industries. It can corrode electronics, semiconductors and nuclear fuel sitting in storage. It also comprises of an explosion hazard. To remove this extra hydrogen, it is possible for chemists to use an organic compound known as a hydrogen getter that chemically binds to a number of hydrogen atoms.

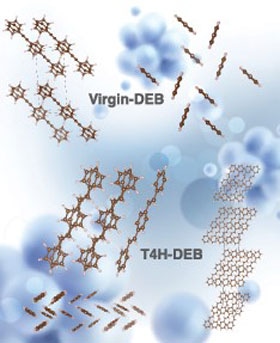

Simulated crystal structures of virgin-DEB and T4H-DEB (chemically known as 1,4-distyrylbenzene, a trans-isomer of DEB intermediate product after the capture of first 4 atomic hydrogen with 2 CH bonds on opposing sides of the carbon chain). The top left and top right structures correspond to side view and top view of virgin DEB, respectively. The middle right, bottom right and bottom left structures correspond to side view, top view and a unit cell (side view) of T4H-DEB, respectively. CREDIT: The simulation was performed by Hom Sharma. Artistic rendering of the image was done by Alexandria Holmberg Diaz, Lawrence Livermore National Laboratory.

Simulated crystal structures of virgin-DEB and T4H-DEB (chemically known as 1,4-distyrylbenzene, a trans-isomer of DEB intermediate product after the capture of first 4 atomic hydrogen with 2 CH bonds on opposing sides of the carbon chain). The top left and top right structures correspond to side view and top view of virgin DEB, respectively. The middle right, bottom right and bottom left structures correspond to side view, top view and a unit cell (side view) of T4H-DEB, respectively. CREDIT: The simulation was performed by Hom Sharma. Artistic rendering of the image was done by Alexandria Holmberg Diaz, Lawrence Livermore National Laboratory.

However, at times, during this binding process – known as catalytic hydrogenation - the partially hydrogenated products become volatile, and thus melt and evaporate before they can bind to more hydrogen atoms. Researchers have now explored how and why this volatility differs during hydrogenation, suggesting that an earlier underappreciated effect from carbon-hydrogen bonds in the molecule is the central culprit.

The new analysis, featured in The Journal of Chemical Physics, from AIP Publishing, can help chemists recognize the perfect conditions needed for catalytic hydrogenation in order to remove excess hydrogen in a better manner.

This creates a model for the behavior of other organic getters, allowing us to predict their optimal operating temperatures and environments.

Long Dinh, Physicist, Lawrence Livermore National Laboratory

Dinh and his colleagues concentrated on a getter known as 1,4 bis(phenylethynyl)benzene, or DEB. To remove hydrogen, crystal flakes of DEB are blended with catalysts in the form of solid pellets. The pellets are developed from activated carbon - whose porous structure offers abundant surface area - coated with palladium nanoparticles. The palladium catalyst is capable of splitting hydrogen molecules into hydrogen atoms, which can then merge to DEB and produce carbon-hydrogen bonds.

DEB is a high-capacity getter that binds with up to eight hydrogen atoms. Most researchers assumed that as getters like DEB bind with more hydrogen atoms and then enlarge, they become a lot volatile. At high operating temperatures, they can vaporize, drifting far from the catalytic pellets where there are no hydrogen atoms with which to bind.

You stop the hydrogenation process prematurely.

Long Dinh, Physicist, Lawrence Livermore National Laboratory

However, the researchers discovered that in the first two steps of hydrogenation, when DEB produces two carbon-hydrogen bonds per step (the carbon-hydrogen bonds are developed on opposite sides of the molecule's carbon chain), the molecule in fact decreases in volatility. DEB becomes more volatile only in subsequent steps of hydrogenation.

The researchers studied how and why DEB changes in volatility by measuring properties such as probed molecular structure, vapor pressures and melting points, and ran quantum mechanical computer simulations that help model the hydrogenation process. Their analysis highlights that the carbon-hydrogen bonds in DEB play a vital role in the molecule's volatile behavior.

During hydrogenation, hydrogen merges with carbon atoms in DEB. According to standard assumption, the resulting carbon-hydrogen bond is nonpolar, wherein neither end of the barbell structure is more positively or negatively charged than the other. However, it turns out that the carbon end is somewhat more negative, and the carbon-hydrogen bond produces a weak dipole, Dinh explained.

As a dipole, a carbon-hydrogen bond is capable of attracting or repelling other carbon-hydrogen bonds in various other DEB molecules. Based on how the carbon-hydrogen bonds are organized and how many are available in the intermediate DEB products, the molecules are capable of either attracting or repelling one another, and thus be more or less volatile, respectively. Earlier research had overlooked these collective interactions amongst carbon-hydrogen bonds in organic crystals, Dinh said.

The researchers, from their analysis, determined that the optimal conditions for DEB hydrogenation is almost below 175 oF, if performed in a good vacuum.

Our results can be applied analogously to other catalytic organic hydrogen getter systems as well.

Long Dinh, Physicist, Lawrence Livermore National Laboratory