Apr 9 2018

Researchers have taken a step ahead on the path toward using lead-free perovskites to manufacture solar cells. Linköping University in Sweden and Nanyang Technological University in Singapore have collaborated to develop high-quality films using double perovskites, which exhibit propitious photovoltaic characteristics.

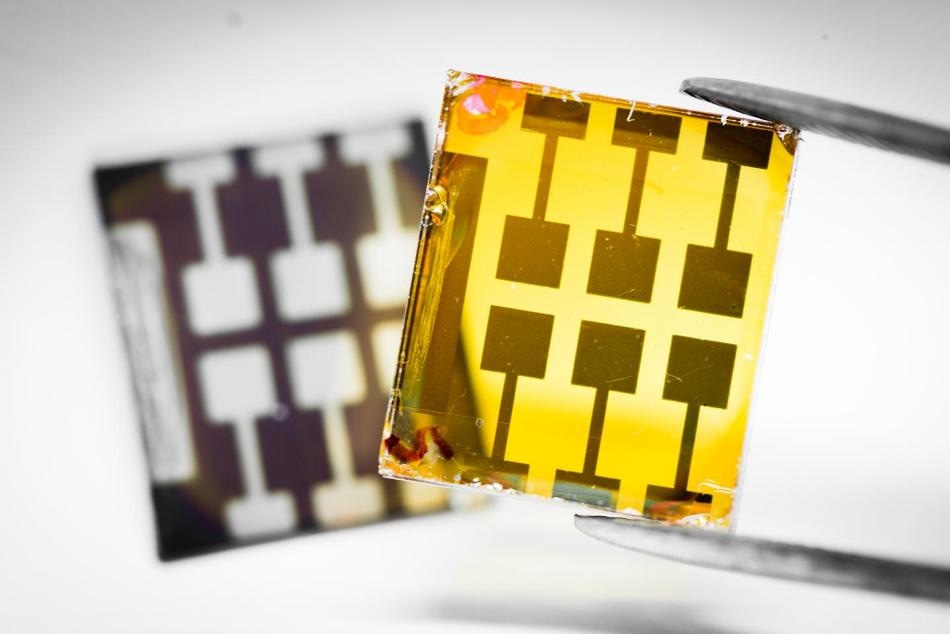

The lead-free double perovskite solar cells (yellow, in the front) compared with the lead-based device (dark, in the background). The next step is to tune the color of the double perovskites into the dark so that they can absorb more light for efficient solar cells. (Image credit: Thor Balkhed)

The lead-free double perovskite solar cells (yellow, in the front) compared with the lead-based device (dark, in the background). The next step is to tune the color of the double perovskites into the dark so that they can absorb more light for efficient solar cells. (Image credit: Thor Balkhed)

Research teams across the globe have identified perovskites as one of the most promising materials for the potential development of efficient, environment-friendly, and inexpensive solar cells. Within a few years, the power conversion efficiency has increased to more than 22%. However, prevalent perovskites that can be used in solar cells consist of lead. In the autumn of 2017, Feng Gao, senior lecturer at LiU, was designated as Wallenberg Academy Fellow to create lead-free double perovskites, in which the divalent lead is replaced by a monovalent metal and a trivalent metal.

Postdoc researchers Weihua Ning and Feng Wang have successfully developed single-layer thin films of densely packed crystals of double perovskites in the laboratory at the Division of Biomolecular and Organic Electronics, LiU. The films have exceptionally high quality and can be used as the active layer in solar cells, where sunlight is absorbed to create charge carriers.

Our colleagues at Nanyang Technological University in Singapore have shown that the charge carriers demonstrate long diffusion lengths in the material, which is necessary if the material is to be appropriate for application in solar cells.

Feng Gao

Although the power conversion efficiency of the solar cells is still low—only about 1% of the solar energy is transformed into electric current—it has not bothered Feng Gao or Weihua Ning.

“No, we have taken the first major step and developed a method to manufacture the active layer. We have several good ideas of how to proceed to increase the efficiency in the near future,” stated Feng Gao.

Weihua Ning agreed to the statement above.

Scientists have computed that more than 4000 different combinations of materials can be used to develop double perovskites. They also propose to use theoretical computations to recognize the combinations that are most appropriate to be used in solar cells.

This advancement in research on double perovskites was made possible by the joint Ph.D. program in Materials and nanoscience/technology at Linköping University and Nanyang Technological University.

This publication is a spin-off of the discussions in relation to the joint Ph.D. programme between NTU-LiU. Two Ph.D. students, one on each side, have been recruited to work on this project. This is an excellent start for the program.

Professor Tze Chien Sum from NTU

“We complement each other very well, the group led by Professor Sum in NTU are experts in photophysics and we are experts in materials science and device physics,” stated Feng Gao.

The outcomes of this study have been reported in Advanced Materials, a prestigious scientific journal.