May 1 2018

Sun is a source of tremendous energy, and harnessing this energy is one of the primary goals to attain a sustainable energy supply.

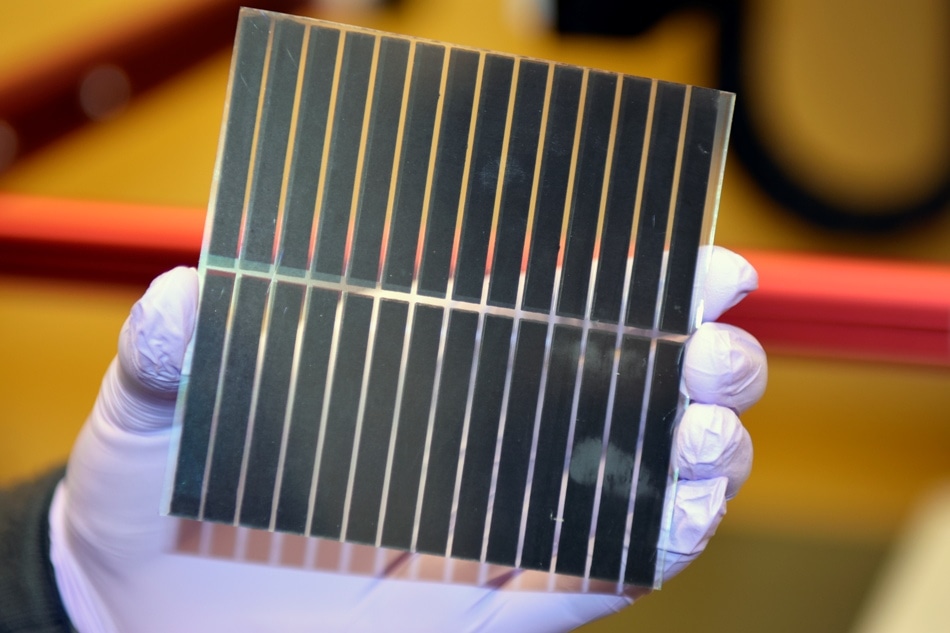

Perovskite solar cells have not yet been produced on a commercial scale. Currently, the OIST Energy Materials and Surface Sciences Unit’s new perovskite solar cells are small enough for Dr. Liu to hold them in the palm of his hand. (Image credit: OIST)

Perovskite solar cells have not yet been produced on a commercial scale. Currently, the OIST Energy Materials and Surface Sciences Unit’s new perovskite solar cells are small enough for Dr. Liu to hold them in the palm of his hand. (Image credit: OIST)

It is possible to convert light energy into electricity directly with the help of electrical devices known as solar cells. Until now, a majority of solar cells have been made of silicon, a material that is an excellent absorber of light. However, manufacturing silicon panels is expensive.

Researchers have been trying to come up with an alternative, made from perovskite structures. True perovskite, a mineral found in the earth, is made up of oxygen, titanium, and calcium in a particular molecular arrangement. Perovskite structures are materials with that specific crystal structure.

Perovskite structures are suitable to be used as the light-harvesting active layer of a solar cell since they efficiently absorb light and cost much lesser than silicon. Moreover, they can be incorporated into devices with the help of comparatively simple equipment. For example, it is possible to spray coat them directly onto the substrate, by dissolving them in a substrate.

While materials produced from perovskite structures may possibly transform solar cell devices, they pose a huge disadvantage: usually very unstable, they deteriorate when exposed to heat. This hampers their commercial viability.

The Energy Materials and Surface Sciences Unit at the Okinawa Institute of Science and Technology Graduate University (OIST), headed by Professor Yabing Qi, has developed devices with the help of a new, stable, and efficient perovskite material that is comparatively inexpensive to manufacture, opening the door for their prospective implementation in the solar cells. Recently, their research featured in Advanced Energy Materials. Key contributors to this work were postdoctoral scholars Dr. Jia Liang and Dr. Zonghao Liu.

This material has various essential characteristics. First, it is entirely inorganic—a significant shift, considering that organic components are often not thermostable and degrade when exposed to heat. Heat stability is vital since there is a likelihood that solar cells can get very hot in the Sun. The scientists used inorganic materials in the place of organic parts and enhanced the stability of the perovskite solar cells to a great extent.

“The solar cells are almost unchanged after exposure to light for 300 hours,” stated Dr. Zonghao Liu, an author on the paper.

Completely inorganic perovskite solar cells generally possess lower light absorption property than organic-inorganic hybrids. Thankfully, they have another feature: The researchers at OIST used manganese to dope their new cells to enhance their performance. Manganese alters the crystal structure of the material, improving its light-harvesting capacity.

“Just like when you add salt to a dish to change its flavor when we add manganese, it changes the properties of the solar cell,” stated Liu.

Next, in such solar cells, the electrodes that transport current between external wires and the solar cells are not made of the usual gold, but carbon. Such electrodes are considerably more inexpensive and easier to manufacture, partially because they can be directly printed onto the solar cells. On the other hand, high temperatures and specialist equipment such as a vacuum chamber are required to fabricate gold electrodes.

There are still several obstacles that stand in the way of perovskite solar cells becoming as commercially viable as silicon solar cells. For instance, perovskite solar cells can last for one or two years as opposed to silicon solar cells, which can function for 20 years.

Qi and his team continue their work on making these new cells more efficient and durable and have also been developing the process of commercial fabrication. Given the rapid pace with which the technology has advanced since the first perovskite solar cell was reported in 2009, these new cells hold a promising future.