May 4 2018

Scientists from The University of Texas at Arlington have created a highly elastic biodegradable hydrogel for bio-printing of materials with the ability to emulate the natural soft tissues of the human body. In bio-printing, live cells are used within the scaffolding of the new tissues, and it could prospectively revolutionize cell printing.

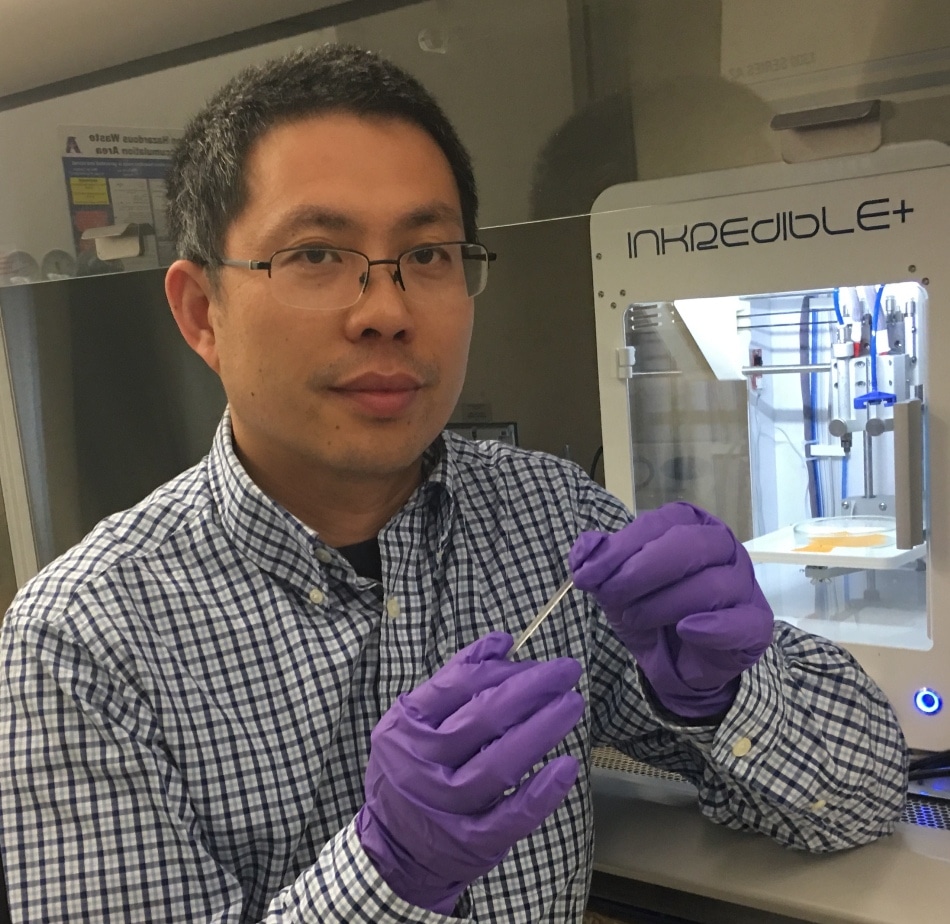

Yi Hong, UTA professor of bioengineering and leader of the project, shows his new hydrogel. (Image credit: The University of Texas at Arlington)

Yi Hong, UTA professor of bioengineering and leader of the project, shows his new hydrogel. (Image credit: The University of Texas at Arlington)

The researchers have filed a provisional patent application on this innovative material, which has the potential to produce different types of human soft tissues, such as heart muscles, blood vessels, skeletal muscles, and skin.

Soft tissue bio-printing suffers from significant challenges as the hydrogels were often brittle and un-stretchable and could not mimic the mechanical behavior of human soft tissues.

Yi Hong, Project Leader & UTA Professor of Bioengineering

To overcome these challenges, we developed a simple system using a single cross-linking mechanism activated by visible light to achieve a highly elastic and robust, biodegradable and biocompatible hydrogel for cell printing.

Yi Hong, Project Leader & UTA Professor of Bioengineering

The outcomes of the study have been reported in a new journal paper titled “Highly Elastic Biodegradable Single-Network Hydrogel for Cell Printing,” recently published in the American Chemical Society’s ACS Applied Materials and Interfaces. The paper was also selected as an American Chemical Society Editors’ Choice.

The innovative hydrogel for cell printing was formed by a tri-block biodegradable polymer of polycaprolactone–poly (ethylene glycol)–polycaprolactone (PCL-PEG-PCL) with two end groups of acrylates and a visible-light water-soluble initiator.

Polycaprolactone and poly (ethylene glycol) are already widely used in Food and Drug Administration–approved devices and implants, which should facilitate quick translation of the material into pre-clinical and clinical trials in the future.

Yi Hong, Project Leader & UTA Professor of Bioengineering

“The tunability of the mechanical properties of this hydrogel to match different soft tissues is a real advantage,” he further stated.

Hong and his team were congratulated by Michael Cho, UTA chair of bioengineering, on this study.

“These colleagues may have created a new way of thinking about hydrogel bio-printing research,” stated Cho. “This work is also critical in advancing UTA’s strategic theme of health and the human condition through cross-disciplinary work.”

Dr. Gaohao Dai from the Northeastern University in Boston also contributed to this study and to the prestigious paper.