Dec 6 2018

When a soft material such as Silly Putty is deformed, its properties vary according to how fast the material is stretched and squeezed. If the putty is left in a small glass, it will in due course spread out like a liquid. If it is pulled slowly, it will thin and droop like viscous taffy. Also, if it is quickly tugged, the Silly Putty will snap like a brittle, solid bar.

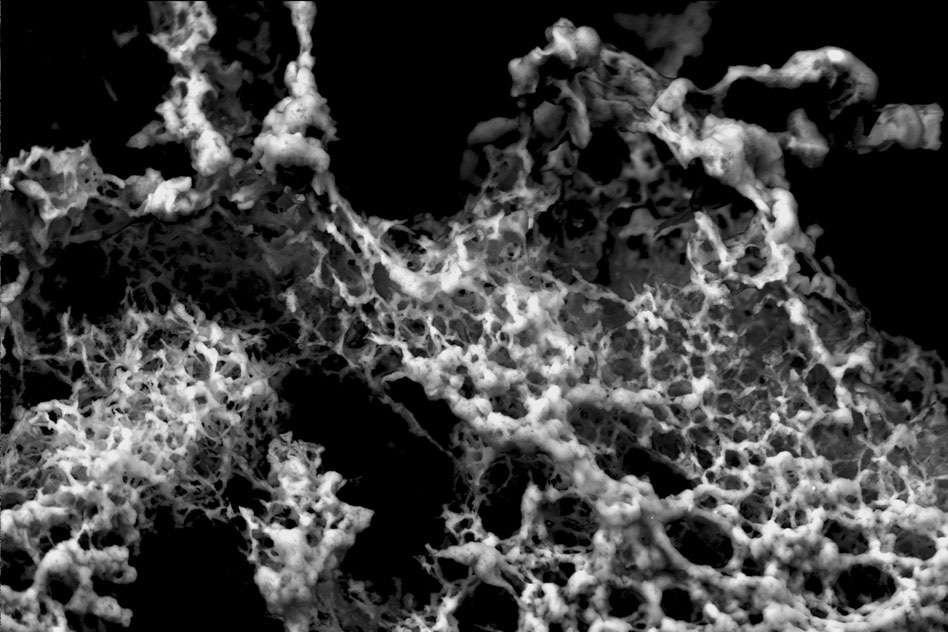

High-resolution E-SEM image of the milk protein network in the casein gel (yogurt) that the researchers were able to characterized using the new OWCh technique during the entire gelation process. (Courtesy of the researchers)

High-resolution E-SEM image of the milk protein network in the casein gel (yogurt) that the researchers were able to characterized using the new OWCh technique during the entire gelation process. (Courtesy of the researchers)

Researchers use numerous instruments to squeeze, stretch, and twist soft materials to precisely describe their elasticity and strength. But usually, such experiments are performed sequentially, which can be laborious.

Now, enthused by the sound sequences used by dolphins and bats in echolocation, MIT engineers have formulated a method that massively improves on the accuracy and speed of measuring soft materials’ properties. The method can be used to examine the properties of clotting blood, drying cement, or any other “mutating” soft materials as they transform over time. The team reports their results in the journal Physical Review X.

“This technique can help in many industries, [which won’t] have to change their established instruments to get a much better and accurate analysis of their processes and materials,” says Bavand Keshavarz, a postdoc in MIT’s Department of Mechanical Engineering.

“For instance, this protocol can be used for a wide range of soft materials, from saliva, which is viscoelastic and stringy, to materials as stiff as cement,” adds graduate student Michela Geri. “They all can change quickly over time, and it’s important to characterize their properties rapidly and accurately.”

Geri and Keshavarz are co-authors on the paper, which also includes Gareth McKinley, the School of Engineering Professor of Teaching Innovation and professor of mechanical engineering at MIT; Thibaut Divoux of the CNRS-MIT joint Laboratory; Christian Clasen of KU Leuven in Belgium; and Dan Curtis of Swansea University in Wales.

Toward faster measurements

The team’s new method enhances and extends the deformation signal that is captured by an instrument called a rheometer. Normally, these instruments are engineered to stretch and squeeze a material, back and forth, over large or small strains, based on a signal transmitted in the form of a simple oscillating profile, which informs the instrument’s motor how rapidly or how far to deform the material. A higher frequency activates the motor in the rheometer to run faster, shearing the material at a quicker rate, while a lower frequency decelerates this deformation down.

Other instruments that examine soft materials function with similar input signals. These can include systems that press and twist materials between two plates, or that mix materials in containers, at forces and speeds established by the frequency profile that engineers program into the instruments’ motors.

Thus far, the most accurate technique for analyzing soft materials has been to do tests consecutively over a long period. During each test, an instrument may, for instance, stretch or shear a material at a single low frequency, or motor oscillation, and record its elasticity and stiffness before moving to another frequency. Although this method produces accurate measurements, it may take hours to completely illustrate a single material.

A ringing chirp

Of late, scientists have been keen to accelerate the process of testing soft materials by altering the instruments’ input signal and compressing the frequency profile that is transmitted to the motors.

Researchers refer to this faster, shorter, and more complex frequency profile as a “chirp,” after the similar structure of frequencies that are created in sonar and radar fields—and very broadly, in certain vocalizations of bats and birds. The chirp profile considerably accelerates an experimental test run, enabling an instrument to measure in just 10 to 20 seconds a material’s properties over a range of speeds or frequencies that traditionally would require nearly 45 minutes.

But in the investigation of these measurements, scientists found artifacts in the data from regular chirps, known as ringing effects, meaning the measurements were not adequately accurate: They appeared to oscillate or “ring” around the anticipated or actual values of stiffness and elasticity of a material, and these artifacts seemed to stem from the chirp’s amplitude profile, which looked like a fast ramp-up and ramp-down of the motor’s oscillation frequencies.

“This is like when an athlete goes on a 100-meter sprint without warming up,” Keshavarz says.

Geri, Keshavarz, and their colleagues aimed to enhance the chirp profile to remove these artifacts and consequently produce more accurate measurements, while maintaining the same short test timeframe. They examined similar chirp signals in sonar and radar—fields initially pioneered at MIT Lincoln Laboratory—with profiles that were originally inspired by chirps produced by bats, birds, and dolphins.

Bats and dolphins send out a similar chirp signal that encapsulates a range of frequencies, so they can locate prey fast,” Geri says. “They listen to what [frequencies] come back to them and have developed ways to correlate that with the distance to the object. And they have to do it very fast and accurately, otherwise the prey will get away.

Michela Geri, Study Co-Author, Graduate Student, MIT

The team examined the chirp signals and enhanced these profiles in computer simulations, then applied specific chirp profiles to their rheometer in the lab. They learned that the signal that lowered the ringing effect most was a frequency profile that was still as short as the conventional chirp signal—about 14 seconds long—but that ramped up slowly, with a smoother transition between the varying frequencies, compared with the original chirp profiles that other scientists have been using.

They name this new test signal an “Optimally Windowed Chirp (OWCh)”, for the resulting shape of the frequency profile, which looked like a smoothly rounded window instead of a sharp, rectangular ramp-up and ramp-down. Eventually, the new method commands a motor to stretch and squeeze a material in a more measured, smooth manner.

The team verified their new chirp profile in the lab on numerous viscoelastic liquids and gels, beginning with a laboratory basic polymer solution which they characterized using the traditional, slower technique, the conventional chirp profile, and their new OWCh profile. They learned that their method produced measurements that almost precisely matched those of the accurate yet slower technique. Their measurements were also 100 times more accurate than what the conventional chirp technique yielded.

The scientists say their method can be applied to any current apparatus or instrument engineered to test soft materials, and it will considerably accelerate the experimental testing process. They have also offered an open-source software package that scientists and engineers can use to help them examine their data, to rapidly characterize any soft, evolving material, from drying cosmetics and clotting blood to solidifying cement.

A lot of materials in nature and industry, in consumer products and in our bodies, change over quite fast timescales. Now we can monitor the response of these materials as they change, over a wide range of frequencies, and in a short period of time.

Bavand Keshavarz, Study Co-Author, Postdoc, Department of Mechanical Engineering, MIT

This study was supported, partially, by Chevron through the MIT Energy Initiative and by a gift from Procter Gamble.

OWCh! Technique inspired by biosonar chirps helps test soft materials