Feb 22 2019

It is believed that the latest generation of lithium-ion (Li-ion) batteries available on the market could prolong the charge-to-charge life of electric cars and phones by around 40%.

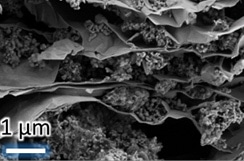

Researchers from Drexel and Trinity College in Ireland have developed a way to intersperse MXene sheets between silicon particles to form a stable anode that would expand the capacity of Li-ion batteries. (Image credit: Trinity College)

Researchers from Drexel and Trinity College in Ireland have developed a way to intersperse MXene sheets between silicon particles to form a stable anode that would expand the capacity of Li-ion batteries. (Image credit: Trinity College)

This development, which emerges after more than 10 years of incremental enhancements, is attributed to developers who are substituting the graphite anode of the battery with the one fabricated from silicon. Now according to a study performed at Drexel University and Trinity College in Ireland, fortifying silicon with a unique type of material known as MXene could lead to an even greater enhancement. Such a modification can prolong the life of Li-ion batteries by up to five times, reported the researchers. The study has been published in Nature Communications.

This is possible thanks to the ability of the two-dimensional (2D) MXene material that prevents the silicon anode from stretching to its breaking point at the time of charging—a challenge that has prevented its application for some time.

Silicon anodes are projected to replace graphite anodes in Li-ion batteries with a huge impact on the amount of energy stored. We’ve discovered adding MXene materials to the silicon anodes can stabilize them enough to actually be used in batteries.

Yury Gogotsi, PhD, Study Co-Author, and Distinguished University and Charles T. and Ruth M. Bach Professor, College of Engineering, Drexel University.

Gogotsi is also the director of the A.J. Drexel Nanomaterials Institute in the Department of Materials Science and Engineering.

The charge in batteries is generally held in electrodes—the anode and cathode—and supplied to the devices as ions pass from anode to cathode. Upon charging the battery, these ions return to the anode. The life of the battery has been gradually increased by identifying means to enhance the ability of the electrodes to transmit and receive more number of ions. If silicon is substituted for graphite as the main material in the Li-ion anode, this would enhance its capacity for absorbing ions. This is because four lithium ions can be accepted by each silicon atom, whereas in graphite anodes, only a single lithium ion is taken in by six carbon atoms. However, as it charges, silicon expands as much as 300%, causing it to break and making the battery to malfunction.

The majority of solutions to resolve this issue involved adding polymer binders and carbon materials to produce a framework for containing the silicon. According to Gogotsi, the process for doing it is extremely complicated and carbon does not contribute much to the charge storage performed by the battery.

On the other hand, in the method developed by the Drexel and Trinity team, silicon powder is mixed into an MXene solution to produce a hybrid silicon-MXene anode. MXene nanosheets create a continuous network by distributing arbitrarily while enveloping around the silicon particles, thereby behaving as conductive binder and additive simultaneously. The same MXene framework also enforces order on ions as they arrive and inhibit the expansion of anode.

MXenes are the key to helping silicon reach its potential in batteries. Because MXenes are two-dimensional materials, there is more room for the ions in the anode and they can move more quickly into it—thus improving both capacity and conductivity of the electrode. They also have excellent mechanical strength, so silicon-MXene anodes are also quite durable up to 450 microns thickness.

Yury Gogotsi, PhD, Study Co-Author, and Distinguished University and Charles T. and Ruth M. Bach Professor, College of Engineering, Drexel University.

MXenes were initially discovered at Drexel University in 2011. To develop this material, a layered ceramic material known as a MAX phase is chemically etched to get rid of a set of chemically-related layers, leaving behind a stack of 2D flakes. So far, over 30 types of MXene have been produced, each having a subtly different set of characteristics. Two of them—titanium carbonitride and titanium carbide—were selected by the team to test the silicon-MXene anodes for the study. The researchers also tested battery anodes that were created from silicon nanoparticles wrapped by graphene.

When compared to existing graphite or silicon-carbon anodes utilized in Li-ion batteries, all three anode samples exhibited higher lithium-ion capacity and more improved conductivity—on the order of 100 to 1,000 times greater than traditional silicon anodes, upon the addition of MXene.

“The continuous network of MXene nanosheets not only provides sufficient electrical conductivity and free space for accommodating the volume change but also well resolves the mechanical instability of Si,” wrote the researchers. “Therefore, the combination of viscous MXene ink and high-capacity Si demonstrated here offers a powerful technique to construct advanced nanostructures with exceptional performance.”

Chuanfang Zhang, PhD, the lead author of the study and a post-doctoral researcher at Trinity, also observed that the fabrication of the MXene anodes, through slurry-casting, can be easily scaled for large-scale production of anodes of any kind of size, meaning that they could be ultimately used in batteries that are capable of powering just about any of the devices.

Considering that more than 30 MXenes are already reported, with more predicted to exist, there is certainly much room for further improving the electrochemical performance of battery electrodes by utilizing other materials from the large MXene family.

Chuanfang Zhang, PhD, Study Lead Author and Post-Doctoral Researcher, Trinity College.

The research was headed by Zhang, a post-doctoral researcher at Trinity College who was a PhD student in Gogotsi's laboratory. It was a collaborative effort between Gogotsi and Trinity professors Jonathan N. Coleman and Valeria Nicolosi, recognized European leaders in the field of 2D materials. Sang-Hoon Park, Andrés Seral-Ascaso, Sebastian Barwich, Niall McEvoy, Conor S. Boland, from Trinity College, also contributed to this research.