Mar 7 2019

Scientists from EPFL’s Laboratory for Processing of Advanced Composites have created a novel material capable of easily healing after being damaged. This innovative composite could be used in aircraft, cars, wind turbines, and sports equipment.

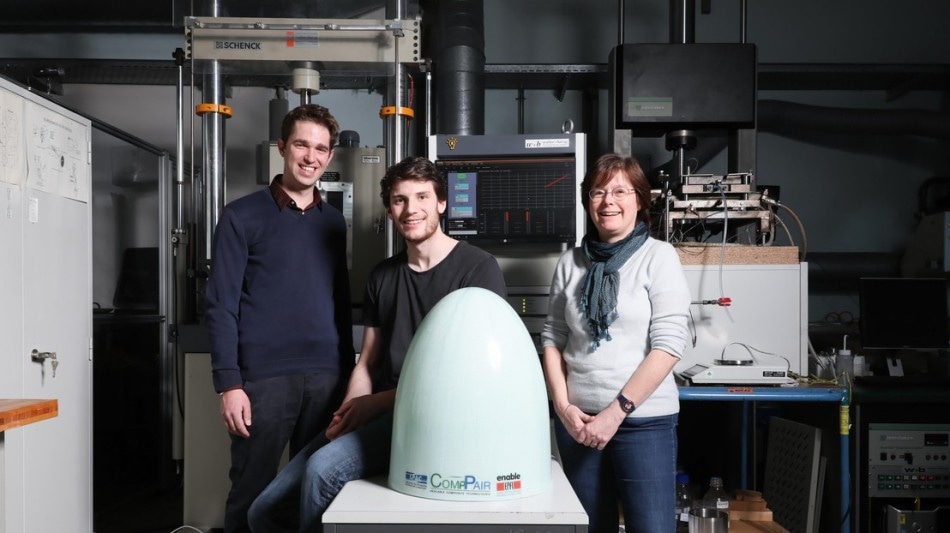

(Image credit: © 2019 EPFL/Alain Herzog)

(Image credit: © 2019 EPFL/Alain Herzog)

When an airplane or a wind turbine blade is hit by an object, the damaged part has to be either switched or repaired using resin. Switching the part is costly, while fixing it with resin can make it heavier and alter its properties. But presently, thanks to a new, patented technology, EPFL scientists have discovered a way to rapidly and easily heal cracks in composite structures.

With our technology, a repair agent is incorporated in the composite material.

Amaël Cohades, Scientist, Laboratory for Processing of Advanced Composites (LPAC), EPFL.

Cracks in the resin can be mended on site within a short span of time by just heating the material to 150 °C. The heating process triggers the repair agent, and the damaged part swiftly heals, without any alteration to the original properties. This new-to-the-market technology can be applied to all types of structures, prolonging their lifetime at least threefold. The material’s properties and primary crack resistance are identical to those of traditional composites. Furthermore, the technology matches with existing manufacturing processes, therefore production units do not have to be retooled.

This technology could mostly be useful for storage tanks and wind turbines. "The cost of maintaining the world's wind turbines alone is estimated at 13 billion Swiss francs in 2020," says Cohades. He says the technology could also be used to "many parts that we don’t bother to repair at present, like bikes and car bumpers." One drawback is that the material does not heal if the impact tears the fibers. But since it is the resin that always gets damaged first, this heat-based self-healing system would still be effective in most cases.

A prototype on display at the World Composites Show

Due to an EPFL enable grant, put together to help EPFL researchers transfer their ideas out of the lab, the scientists were able to develop a regular aerospace prototype. This component, made from fiberglass-reinforced resin, shows the mechanism of the healing process. It will be showcased at the JEC World Composites Show in Paris between March 12th and 14th, 2019. Additionally, the scientists are, at present, putting together a startup to sell the new materials.