Nov 11 2019

productronica 2019 will see the launch of the xReflow™ Heated Stage. Visit Hall A2 Booth 534 to learn more about this new exciting development in real-time observation of void formation using X-ray.

With the continuous quest for higher yields in electronics production, the problem of void formation in solder joints, particularly in BGAs and QFNs, is now very much in focus.

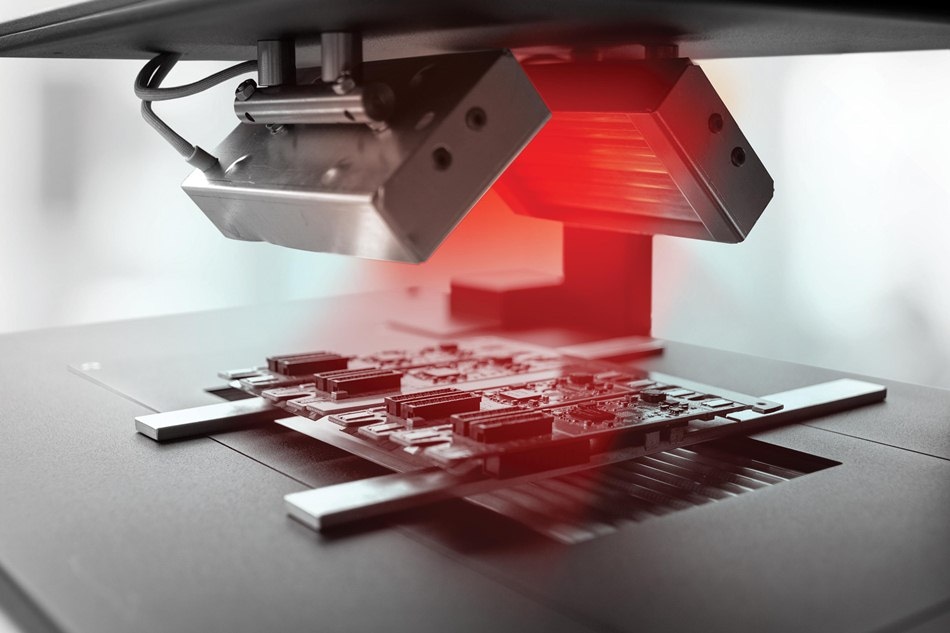

The xReflow Heated Stage is a software PID-controlled IR Micro heater, which can be mounted inside almost any off-line X-ray system to observe void and defect formation during reflow, as it happens.

The PCB with components and solder paste is positioned in the oven ready for observation. The X-ray tube is positioned, with magnification and focus set for the area of interest, the image can be either a perpendicular or oblique view.

When setup is complete, the X-ray is switched to view live images, the xReflow heating cycle is started and the entire reflow process can be observed (and recorded) in real-time.

As voids and defects form, we can observe them, note the part of the reflow cycle they occur and start to investigate how to eliminate them. This allows us to modify the reflow cycle to reduce voiding or defect formation on problem components or areas of the assembly. All profile parameters can be modified allowing the best possible results to be achieved.

Our customers also use xReflow to evaluate new solder pastes and other joining materials. Advanced joining material suppliers also use this system as part of their product development process.

Etek Europe Ltd are the global distributors for the xReflow.