Jan 23 2020

Mammals are known to regulate their body temperatures through sweating. Now, scientists at Shanghai Jiao Tong University based in China are investigating whether the same process could also be mimicked by phones.

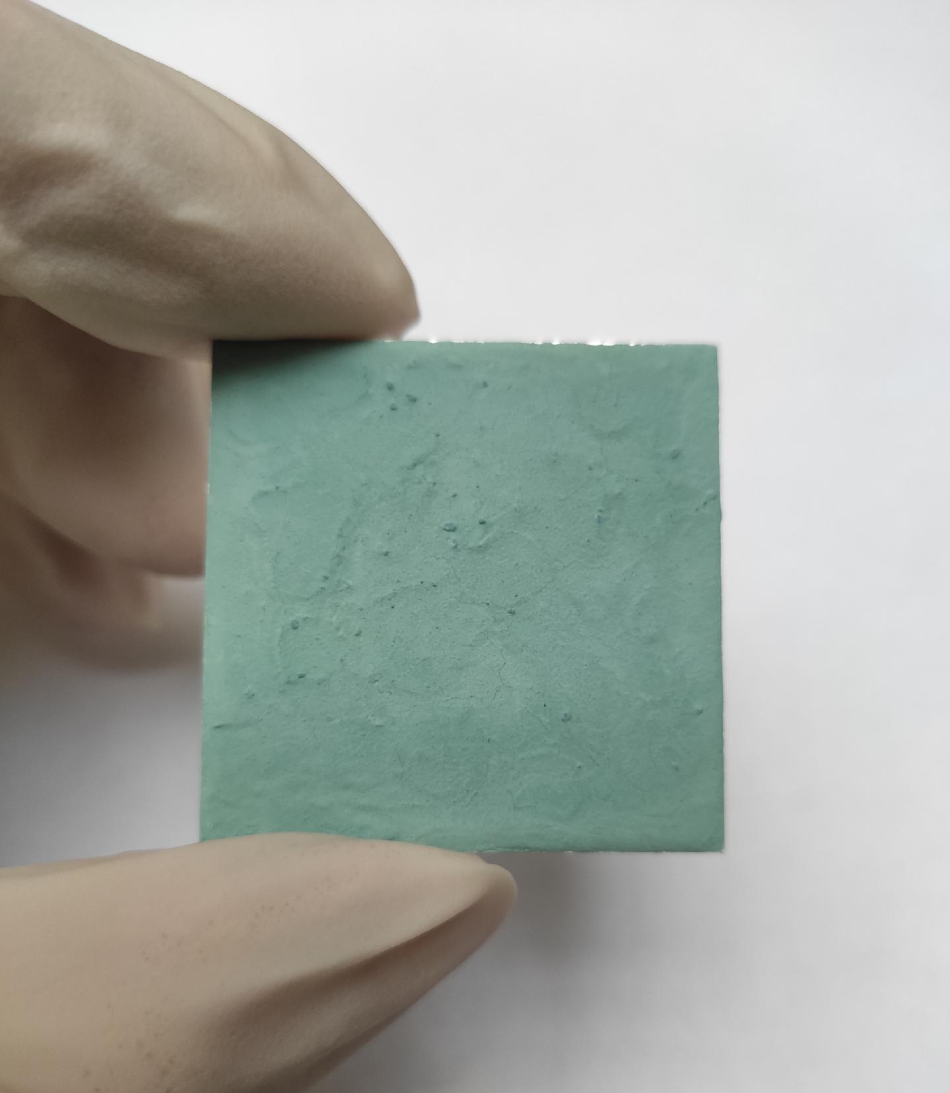

This image shows a MIL-101(Cr) coating on an aluminum sheet. Image Credit: Chenxi Wang

This image shows a MIL-101(Cr) coating on an aluminum sheet. Image Credit: Chenxi Wang

The study was published in the Joule journal on January 22nd, 2020, where the authors have demonstrated a new type of coating for electronics that dissipates heat from running devices by discharging water vapor. This novel thermal management technique can prevent overheating in electronics and thus keep them cooler when compared to present strategies.

The development of microelectronics puts great demands on efficient thermal management techniques, because all the components are tightly packed and chips can get really hot. For example, without an effective cooling system, our phones could have a system breakdown and burn our hands if we run them for a long time or load a big application.

Ruzhu Wang, Study Senior Author, Shanghai Jiao Tong University

Wang studies refrigeration engineering at Shanghai Jiao Tong University.

Computers and other similar larger devices make use of fans to control temperature, but fans are not suitable for smaller devices such as cell phones because they are noisy, heavy, and consume a lot of energy.

To achieve cooling in cell phones, manufacturers have been utilizing phase change materials (PCMs) such as fatty acids and waxes. Such materials are capable of absorbing heat created by devices while melting. However, the overall energy that is exchanged during the transition from solid to liquid is comparatively low.

On the other hand, the amount of energy exchanged during the liquid-vapor transition of water is 10 times that of the PCM solid-liquid transition.

Motivated by the sweating mechanism of mammals, Wang and his research team examined a class of porous materials that can potentially absorb atmospheric moisture and discharge water vapor upon heating.

Among this group of porous materials, metal-organic frameworks (MOFs) were found to be highly promising since they can store a large quantity of water and thus remove excess amounts of heat upon heating.

Previously, researchers have tried to use MOFs to extract water from the desert air. But MOFs are still really expensive, so large-scale application isn’t really practical. Our study shows electronics cooling is a good real-life application of MOFs. We used less than 0.3 grams of material in our experiment, and the cooling effect it produced was significant.

Ruzhu Wang, Study Senior Author, Shanghai Jiao Tong University

For the experiment, the researchers chose a type of MOF known as MIL-101(Cr) because of its high sensitivity to temperature variations and excellent water-absorbing capacity. The team initially coated three 16 cm2 aluminum sheets with MIL-101(Cr) of varying thicknesses—198, 313, and 516 µm, respectively, and then heated the aluminum sheets on a hot plate.

The researchers discovered that the MIL-101Cr coating effectively delayed the temperature rise of the aluminum sheets, and the impact increased with the thickness of the coating.

An uncoated aluminum sheet reached a temperature of 60 °C after a period of 5.2 minutes, while the thinnest coating increased the time by twofold and did not reach the same temperature until 11.7 minutes. After 19.35 minutes of heating, the aluminum sheet with the thickest coating reached a temperature of 60 °C.

“In addition to effective cooling, MIL-101(Cr) can quickly recover by absorbing moisture again once the heat source is removed, just like how mammals rehydrate and ready to sweat again,” Wang added. “So, this method is really suitable for devices that aren’t running all the time, like phones, charging batteries and telecommunications base stations, which can get overloaded sometimes.”

Along with his research team, Wang tested a coated heat sink on a microcomputing device to analyze the cooling effect of MIL-101(Cr) on real devices. In comparison to an uncoated heat sink, the coated heat sink decreased the temperature of the chip by up to 7 °C when the device was running for 15 minutes at heavy workloads.

The researchers are next planning to enhance the thermal conductivity of the material.

Once all the water is gone, the dried coating will become a resistance that affects devices’ heat dissipation.

Chenxi Wang, Study First Author, Shanghai Jiao Tong University

He added that integrating thermal conductive additives such as graphene into the material could help to overcome the issue.

Wang further stated that cost is a major problem before manufacturers can integrate this cooling system into their phones.

“By finding MOFs a practical application, we hope to increase the market demand for them and encourage more research on MOFs to bring down the costs,” concluded Wang. The study was supported by the Foundation for Innovative Research Groups of the National Natural Science Foundation of China.