Oct 16 2020

Scientists from Stanford University and the SLAC National Accelerator Laboratory at the U.S. Department of Energy (DOE) have adopted an entirely new method for making safer, lighter, and more efficient lithium-ion batteries.

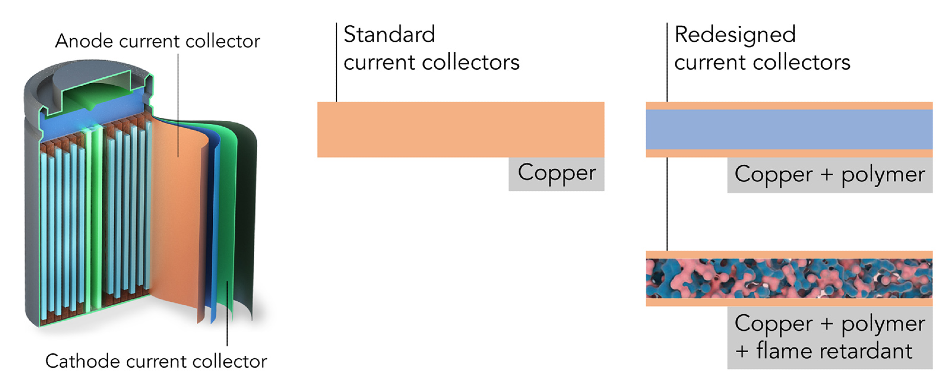

Scientists at Stanford and SLAC redesigned current conductors—thin metal foils that distribute current to and from electrodes—to make lithium-ion batteries lighter, safer, and more efficient. They replaced the all-copper conductor, middle, with a layer of lightweight polymer coated in ultrathin copper (top right), and embedded fire retardant in the polymer layer to quench flames (bottom right). Image Credit: Yusheng Ye/Stanford University.

Scientists at Stanford and SLAC redesigned current conductors—thin metal foils that distribute current to and from electrodes—to make lithium-ion batteries lighter, safer, and more efficient. They replaced the all-copper conductor, middle, with a layer of lightweight polymer coated in ultrathin copper (top right), and embedded fire retardant in the polymer layer to quench flames (bottom right). Image Credit: Yusheng Ye/Stanford University.

The team has redesigned one of the heaviest components of batteries—sheets of aluminum or copper foil called current collectors—so that they can readily extinguish any fires that flare up and weigh 80% less.

According to the researchers, if this technology is adopted, it may help address two significant objectives of battery research—that is, minimizing the risk of fires in cell phones, laptops, and other devices, and expanding the driving range of electric vehicles.

This is particularly crucial when batteries are charged super-fast, leading to more of the kinds of battery damage that can cause fires. The researchers have recently explained their study in the Nature Energy journal.

The current collector has always been considered dead weight, and until now it hasn’t been successfully exploited to increase battery performance. But in our study, making the collector 80% lighter increased the energy density of lithium-ion batteries—how much energy they can store in a given weight—by 16-26%. That’s a big jump compared to the average 3% increase achieved in recent years.

Yi Cui, Professor, SLAC National Accelerator Laboratory and Stanford University

Cui is also an investigator with the Stanford Institute for Materials and Energy Sciences (SIMES), which headed the study.

Desperately Seeking Weight Loss

Whether lithium-ion batteries come in the form of pouches or cylinders, they contain a pair of current collectors—one for every electrode. These collectors distribute the current that flows in or out of the electrode and are responsible for 15% to as high as 50% of the weight of certain ultrathin or high-power batteries.

Reducing a battery’s weight is preferable in itself, resulting in lighter devices and decreasing the proportion of weight that had to be carried around by electric vehicles. Moreover, storing more amounts of energy for each specified weight enables both electric vehicles and devices to work longer between the charge cycles.

Decreasing flammability and battery weight may also have a major effect on recycling by making it less costly to transport the recycled batteries, added Cui.

Scientists in the battery sector have been looking for ways to decrease the weight of current collectors by rendering them more porous and thinner; however, these attempts have led to undesirable side effects, like needing more electrolyte or making batteries more delicate or chemically unstable.

This, in turn, increases the cost, stated Yusheng Ye, a postdoctoral researcher working in Cui’s laboratory and who performed the experiments with Lien-Yang Chou, a visiting scholar.

As far as the safety issue is concerned, “People have also tried adding fire retardant to the battery electrolyte, which is the flammable part, but you can only add so much before it becomes viscous and no longer conducts ions well,” Ye added.

Designing a Polymer-Foil Sandwich

After working around the issue, Cui, Ye, and Yayuan Liu, a graduate student, designed experiments for producing and testing current collectors built on polyimide—a lightweight polymer. This polymer is not only impervious to fires but can also withstand the extreme temperatures produced by rapid battery charging.

The polymer was integrated with triphenyl phosphate (TPP), a type of fire retardant, and then coated on either surface with an ultrathin copper layer. In addition to doing its regular task of distributing current, the copper also protects the polymer and the fire retardant.

Such changes decreased the weight of the current collector by as much as 80% when compared to present-day models, added Ye. This leads to an energy density increase of 16% to 26% in different types of batteries, and it conducts current equally well as standard collectors without any sign of degradation.

When the team exposed the pouch batteries—made with commercially available current collectors—to an open flame from a lighter, the batteries instantly caught fire and burned intensely until the entire electrolyte burned away, added Ye.

However, in the case of batteries containing the new flame-retardant collectors, the fire never flared up and instead created extremely weak flames that extinguished within a few seconds and never flared up even when the researchers attempted to reignite it.

According to Cui, one of the major benefits of this method is that the novel collector can be easily produced and is also more cost-effective because it substitutes some of the copper with a low-cost polymer. Therefore, upgrading it for commercial production “should be very doable,” Cui stated.

The team has applied for a patent through Stanford University, and will be contacting battery producers to investigate new possibilities, Cui concluded.

The study was funded by the DOE’s Office of Energy Efficiency and Renewable Energy, Vehicle Technologies Office under the eXtreme Fast Charge Cell Evaluation of Lithium-ion Batteries (XCEL) program.

Journal Reference:

Ye, Y., et al. (2020) Ultralight and fire-extinguishing current collectors for high-energy and high-safety lithium-ion batteries. Nature Energy. doi.org/10.1038/s41560-020-00702-8.