Nov 23 2020

The U.S. Department of Energy’s Office of Energy Efficiency and Renewable Energy celebrates the National Hydrogen and Fuel Cell Day each year on October 8th (since 2015) to highlight hydrogen-based technological progress made.

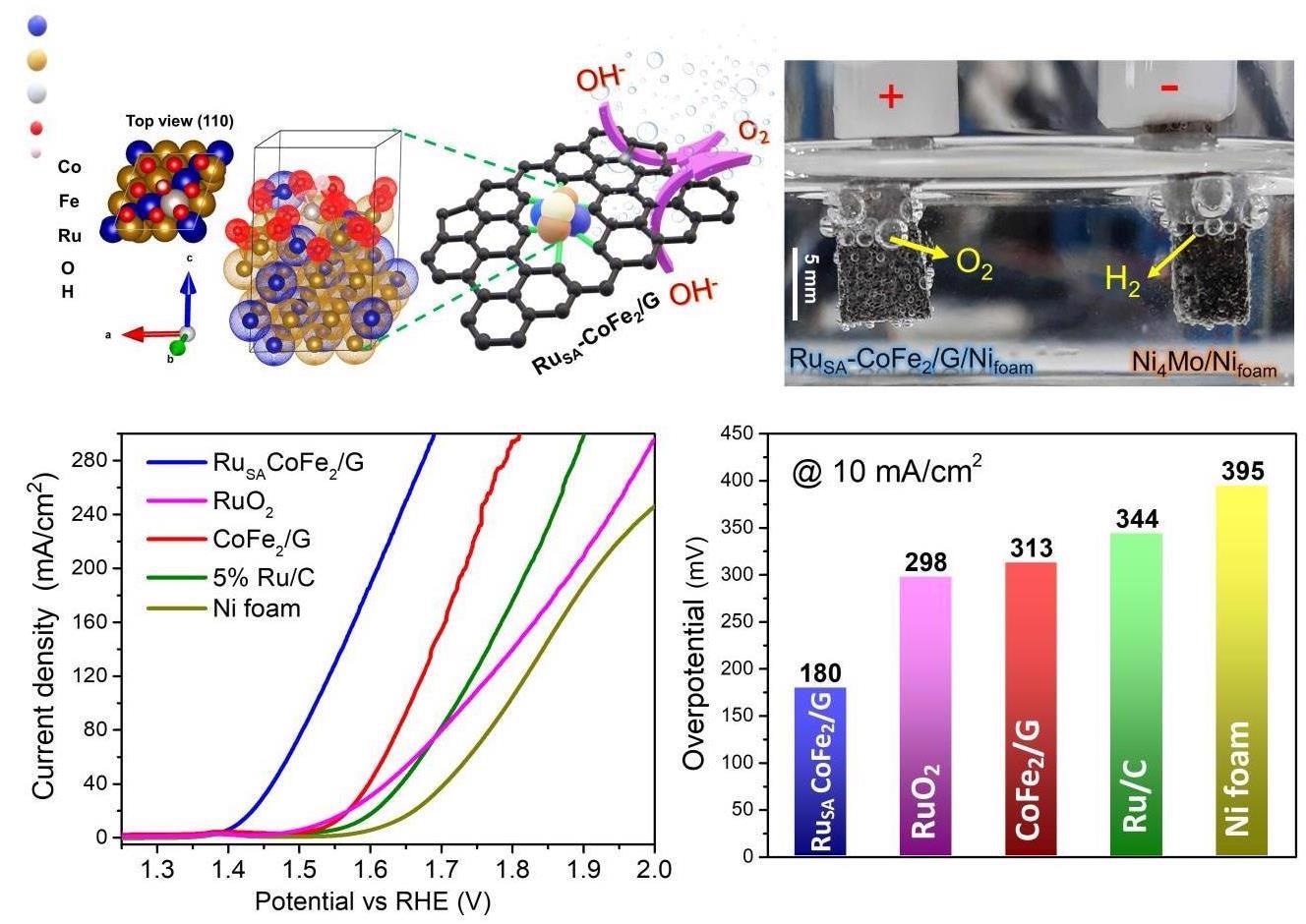

Crystal structure of surface oxygen-rich metal alloy (top left). Oxygen and hydrogen are generated during a water electrolysis reaction (top right). The designed catalyst exhibits the best oxygen evolution activity with minimal overpotential (bottom panels). Image Credit: IBS.

Crystal structure of surface oxygen-rich metal alloy (top left). Oxygen and hydrogen are generated during a water electrolysis reaction (top right). The designed catalyst exhibits the best oxygen evolution activity with minimal overpotential (bottom panels). Image Credit: IBS.

The date was chosen to signify hydrogen’s atomic weight of 1.008. Hydrogen, the most common molecule in the universe, is not only abundant but also clean and versatile.

When hydrogen is spent in a fuel cell (which takes the water molecule (H2O) and separates it into hydrogen and oxygen, a process called electrolysis), it generates electricity, water, and heat. As a zero-carbon energy source, the range of its probable use is immeasurable: transportation, industrial, residential, commercial, and portable.

In contrast to conventional hydrogen synthesizing processes that demand fossil fuels or CO2, electrolysis yields “green hydrogen” from water molecules. Since water cannot be separated into hydrogen and oxygen by itself, the electrochemical hydrogen-water conversion requires very active electrocatalysts.

The traditional water electrolysis, however, poses technological challenges in enhancing the efficiency of the water-splitting reaction for the slow oxygen evolution reaction. Noble metal-based iridium oxide (IrO2) and ruthenium oxide (RuO2) are used to improve the oxygen generation rate. But these noble metal catalysts are very costly and exhibit poor stability under continuous operation.

The IBS team, headed by Associate Director LEE Hyoyoung of the Center for Integrated Nanostructure Physics within the Institute for Basic Science (IBS) situated at Sungkyunkwan University, created a very efficient and durable electrocatalyst for water oxidation using iron, cobalt, and a tiny quantity of ruthenium.

We used ‘amphiphilic block copolymers’ to control electrostatic attraction in our single ruthenium (Ru) atom-bimetallic alloy. The copolymers facilitate the synthesis of spherical clusters of hydrocarbon molecules whose soluble and insoluble segments form the core and shell.

Jinsun Lee and Kumar Ashwani, Study Co-First Authors, IBS

“In this study, their tendency for a unique chemical structure allows the synthesis of the ‘high-performance’ single atomic Ru alloy present atop the stable cobalt iron (Co-Fe) metallic composite surrounded by porous, defective and graphitic carbon shell,” added Lee and Ashwani.

We were very excited to discover that pre-adsorbed surface oxygen on the Co-Fe alloy surface, absorbed during the synthesis process, stabilizes one of the important intermediates (OOH*) during the oxygen generation reaction, boosting the overall efficiency of the catalytic reaction. The pre-absorbed surface oxygen has been of little interest until our finding.

Hyoyoung Lee, Study Corresponding Author and Associate Director, IBS

The team discovered that four-hour annealing at 750 °C in an argon atmosphere is the most suitable setting for the oxygen production process. Besides the reaction-friendly environment on the host metal surface, the single Ru atom, where oxygen production occurs, also meets its role by decreasing the energy barrier, thus synergistically increasing the efficiency of oxygen evolution.

The researchers assessed the catalytic efficiency with the overvoltage metrics required for the oxygen evolution reaction. The advanced noble electrocatalyst needed just 180 mV (millivolt) overvoltage to achieve a current density of 10 mA (milliampere) per cm2 of catalyst, while RuO2 required 298 mV.

Furthermore, the single Ru atom-bimetallic alloy exhibited high stability for 100 hours without any structural change. Additionally, the iron and cobalt alloy with graphitic carbon also compensated electrical conductivity and improved the oxygen evolution rate.

This study takes us a step closer to a carbon-free, and green hydrogen economy. This highly efficient and inexpensive oxygen generation electro-catalyst will help us overcome long-term challenges of the fossil fuel refining process: to produce high-purity hydrogen for commercial applications at a low price and in an eco-friendly manner.

Hyoyoung Lee, Study Corresponding Author and Associate Director, IBS

Journal Reference:

Lee, J., et al. (2020) Stabilizing OOH* intermediate via pre-adsorbed surface oxygen of single Ru atom-bimetallic alloy for ultralow overpotential oxygen generation. Energy & Environmental Science. doi.org/10.1039/D0EE03183F.