Dec 16 2020

Scientists at Yokohama National University and the University of Electro-Communications in Japan have created a highly efficient method to synthesize an exclusive fullerene crystal, known as fullerene finned-micropillar (FFMP).

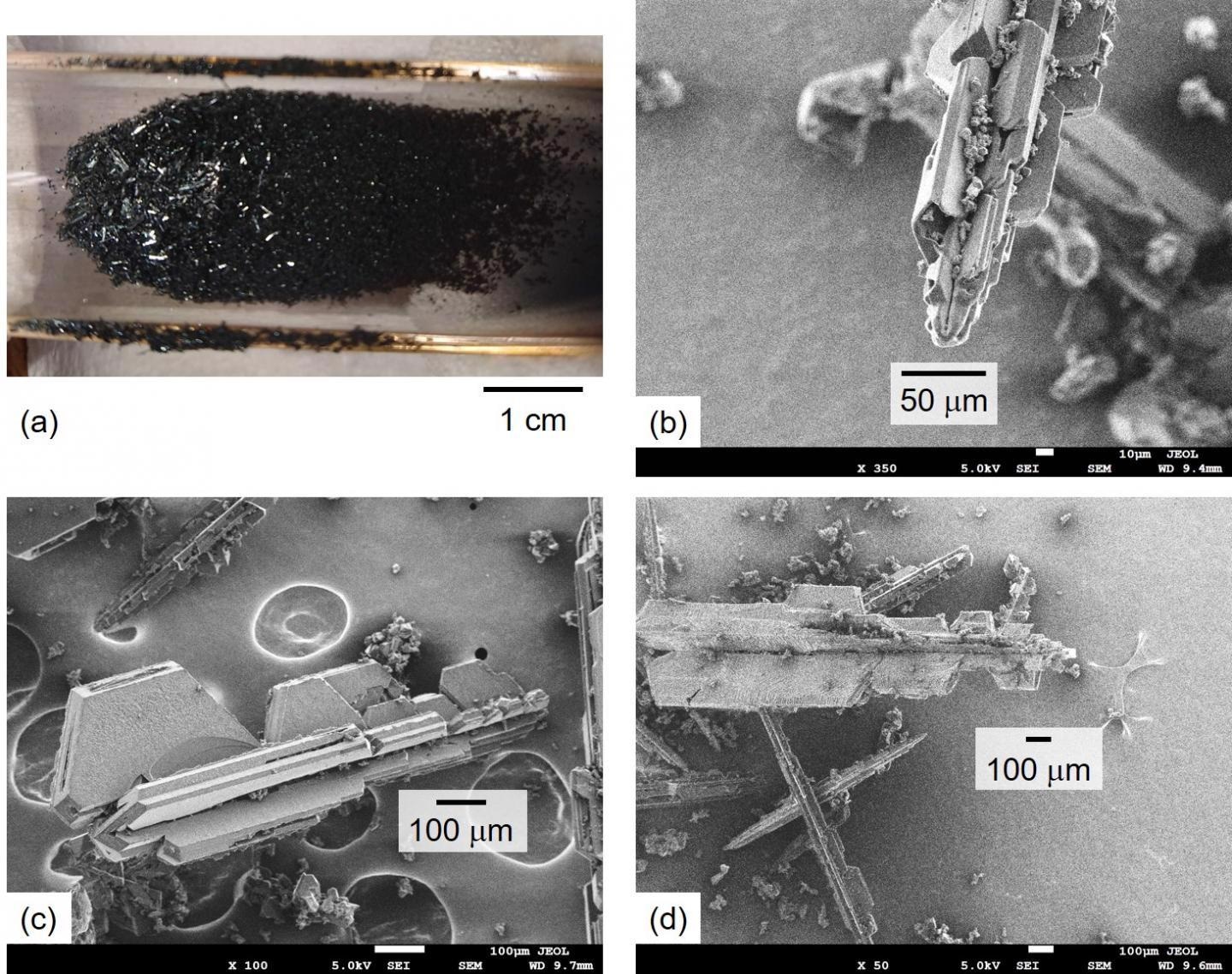

(a) Photo of produced FFMP on quarts plate and (b to d) scanning electron microscope images of samples. Image Credit: Yokohama National University.

(a) Photo of produced FFMP on quarts plate and (b to d) scanning electron microscope images of samples. Image Credit: Yokohama National University.

The new fullerene crystal could find crucial use for next-generation electronics. Fullerene is a desirable choice to create technologies, not just because of its small size but also because it exhibits semiconductor properties and is highly durable, which makes it an ideal candidate in devices like superconductive materials, field-effect transistors, chemical sensors, and solar cells.

Although fullerene is currently in use, it is challenging to handle because the material is a nano-scale one and often exists in a powdery state. One-dimensional fullerene crystals are synthesized and used to overcome this problem.

Producing one-dimensional fullerene crystals requires expert skills and takes several days with typical production methods. In this study, we succeeded in developing a very simple fabricating method by using an annealing process.

Dr Takahide Oya, Study Corresponding Author and Associate Professor, Yokohama National University

In a paper published in November 2020 in the Scientific Reports journal, the researchers describe how a small heating apparatus that accepts fullerene was used to heat it to a temperature of 1,173 K for approximately an hour.

The fullerene deposited initially in the heating apparatus gets de-crystallized under the impact of heat and then re-crystallizes upon reducing the temperature. Dubbed annealing, this overall process is more than 50 times faster compared to the previous method for synthesizing fullerene crystals.

By using our method, mass production of one-dimensional fullerene crystals can be produced in an hour. The produced fullerene crystals that we named ‘fullerene finned-micropillar (FFMP)’ have a distinctive structure.

Dr Takahide Oya, Study Corresponding Author and Associate Professor, Yokohama National University

The researchers believe that the fullerene crystals synthesized through the new, more efficient process will have qualities analogous to fullerene nanowhiskers made using the previous techniques.

“FFMP is expected to have electrical conductivity and n-type semiconductor functionality,” added Oya.

More tests would have to be performed to verify whether FFMP actually retains the qualities useful for electronic implementation. However, positive results could relate to solar cells with considerably higher efficiency and very small circuits integrated into flexible devices, for example.

The researchers have already analyzed this annealing under various environmental conditions, heating time, and temperatures. After analyzing the process, the focus of the researchers is now on characterizing the FFMP in the context of an electrical component.

As the next step of this study, confirming and obtaining the electrical conductivity and the n-type semiconductor functionality is expected, because the ordinary fullerene has such properties. In addition, developing ‘fullerene-finned nano pillar (FFNP)’ by modifying the process is also expected. We believe that FFMPs (or FFNPs) will be useful for field-effect transistors, organic photovoltaics, and so on in the near future.

Dr Takahide Oya, Study Corresponding Author and Associate Professor, Yokohama National University

This is not the first time Oya and his colleagues have dealt with exclusive, small-scale materials for use in electronics.

“We have already had a technique for making carbon nanotube, or CNT—one dimensional nano-carbon material—composite papers and CNT composite threads/textiles as unique CNT composite materials,” noted Oya.

“Therefore, we will develop FFMP composite materials along with their applications. We believe the useful FFMP composites (and the combination with CNT composites) will be used in our daily life in near future,” Oya concluded.

Journal Reference:

Onishi, T., et al. (2020) Simple annealing process for producing unique one-dimensional fullerene crystal named fullerene finned-micropillar. Scientific Reports. doi.org/10.1038/s41598-020-76252-6.