A newly designed coating that enables some liquids to move throughout surfaces without any loss of fluid can power new advancements in various fields, such as medical testing.

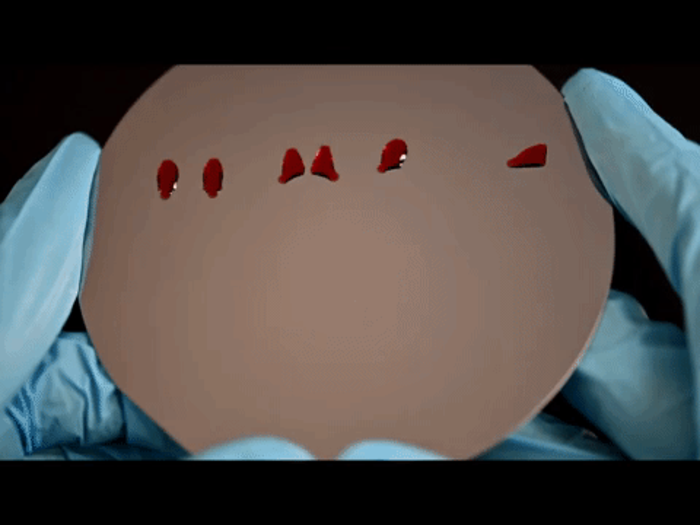

New polymer coatings, developed by Professor Kevin Golovin (MIE) and his team, show the precision with which liquids can move across surfaces. Image Credit: Mohammad Soltani.

New polymer coatings, developed by Professor Kevin Golovin (MIE) and his team, show the precision with which liquids can move across surfaces. Image Credit: Mohammad Soltani.

The new coating — made in the DREAM (Durable Repellent Engineered Advanced Materials) Laboratory, headed by Professor Kevin Golovin (MIE) — gained inspiration from the natural world.

Nature has already developed strategies to transport liquids across surfaces in order to survive. We were inspired by the structural model of natural materials such as cactus leaves or spider silk. Our new technology can directionally transport not only water droplets, but also low surface tension liquids that easily spread on most surfaces.

Mohammad Soltani, Study Lead Author and MIE PhD Candidate, Researcher in the DREAM Laboratory, University of Toronto

The study has been published in the Advanced Functional Materials journal.

The novelty has significant implications for microfluidics. It is a field where small amounts of liquids are transported inside tiny channels, usually measuring less than a millimeter wide. This method has several applications, where one of them is to miniaturize the normal analytical tests that are executed at present in the chemical laboratories.

By decreasing the number of samples and reagents needed, as well as automating protocols for operating with them, microfluidics could power lab-on-a-chip devices that provide quick and low-cost medical tests. Researchers believe this could result in diagnosing several conditions in minutes using just a drop or two of blood.

However, present microfluidic devices exhibit a major drawback: they are only capable of effectively handling liquids with high surface tension, like water. This property, also called cohesion, implies that the liquid has a higher tendency to adhere to itself compared to the sides of the channel it is being transported through.

Liquids with high surface tension tend to develop separate droplets that have the ability to be moved around individually, similar to raindrops on window glass. Also, cohesion can be used to pull the liquid droplets along the channel via a process called capillary action.

On the other hand, low surface tension liquids, like alcohols and other solvents, tend to stay to the sides of the channels and can only be transported for about 10 mm before the droplet starts to fall apart. Hence, capillary action no longer seems to be effective and so this transport needs an external force, like heat or magnetism, to shift the droplets.

The new coating allows low surface tension liquids to be carried over distances of more than 150 mm without the loss of any liquid, nearly 15 times longer compared to what is possible at present.

Two newly developed polymer coatings have been utilized for the technology, one of which is more liquid-repellent compared to the other. Both are made up of liquid-like polymer brushes. The more repellent coating serves as a background, encircling the less repellent coating and thus making tiny channels ahead of the surface. Thus, the channels enable the liquids to move in a preferred pattern or direction without losing any of the liquid at the time of transport or necessitating more energy input.

Polymer brush coatings reduce the fluid friction and allow the droplets to be transported passively. Less friction means more energy is available to transport the liquid. We then create a driving force by designing the channels with specific patterns.

Mohammad Soltani, Study Lead Author and MIE PhD Candidate, Researcher in the DREAM Laboratory, University of Toronto

The potential to transport liquids of low surface tension without any loss will enable developments in lab-on-a-chip devices. Such special coatings will enable scientists to transport liquids over a longer range, move several liquids at the same time along an accurate pathway and even combine and split droplets. All this is done without losing any volume or undergoing cross-contamination.

Furthermore, this technology will help limit waste in research laboratories. Since there is no residue left behind on the surface of the device and thus no risk of cross-contamination, scientists can make use of the same devices repeatedly.

We’re looking at using this technology for microfluidics bioassays, as this is an area where every drop of liquid is precious. Our findings also have great potential to advance point-of-care diagnostics, such as liver or kidney disease, where biological marker screening is often performed in non-aqueous media.

Kevin Golovin, Study Corresponding Author and Professor, University of Toronto

Video Credit: University of Toronto.

Journal Reference:

Soltani, M & Golovin, K (2021) Lossless, Passive Transportation of Low Surface Tension Liquids Induced by Patterned Omniphobic Liquidlike Polymer Brushes. Advanced Functional Materials. doi.org/10.1002/adfm.202107465.