The novel study published in the journal Electrochimica Acta is focused on catalyst ink composition effect on the current-voltage characteristics of fuel cells.

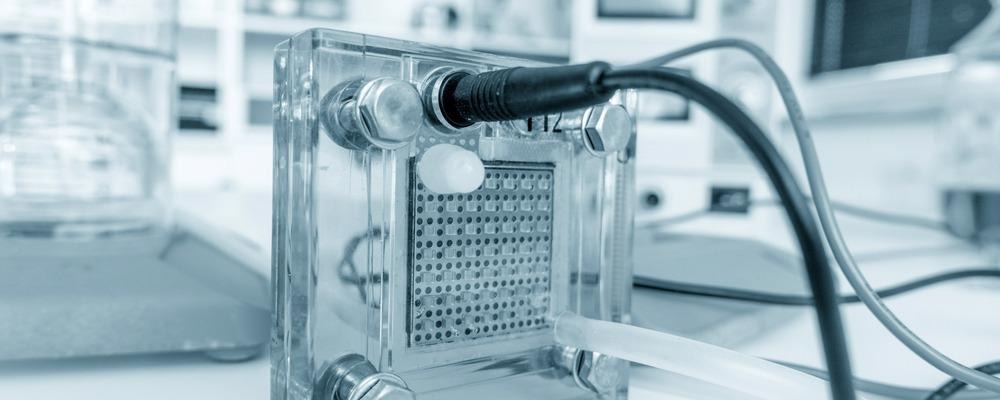

Study: Catalyst layers for fluorine-free hydrocarbon PEMFCs. Image Credit: luchschenF/Shutterstock.com

Fuel Cells and Limitations

According to the latest study, energy storage devices are essential for a sustainable future. Because of its extremely low temperatures, high energy conversion efficacy, quick start-up, zero carbon emissions at point-of-use, and system adaptability, proton exchange membrane fuel cells (PEMFC) seem promising.

However, major obstacles to large-scale industrialization remain the cost, functionality, and longevity of the membrane electrode-assemblies (MEA) that compose fuel cell stacks.

Perfluorosulfonic Acid and Limitations

A perfluorosulfonic acid (PFSA) ionomer, such as Nafion®, is frequently used as both the proton exchange membrane (PEM) and the ionomer. PFSAs have high ionic conductivity, as well as superior mechanical qualities, chemical inertness, and endurance.

However, perfluorinated materials are not without hurdles, since their production involves the use of regulated compounds and potentially dangerous chemical feedstock, which contributes to their comparatively expensive cost. Furthermore, PFSAs' high gas penetration and instability at high temperatures and low relative humidity limit their use.

Materials

The materials included Sulfonated phenylated poly(phenylene) biphenyl (sPPB-H+) (IEC = 3.23 ± 0.04 meq g−1) which was synthesized. Others include Pt/C catalyst powder containing Ketjen Black (TEC10E50E, lot 109–0111, 46.5 wt% Pt) and Vulcan XC-72. Sigracet 22BB PTFE-treated gas diffusion layers (GDL) were purchased for the experiment. Methanol (MeOH, ACS reagent ≥ 99.8%) and isopropanol (iPrOH. ACS reagents≥ 99.8% were also used in the experimental study.

Experimental Methods

sPPB-H+ films were made from a 7.5 wt % DMSO solution (ACS reagent 99.9%). The barrier was prepared by dispersing 10 g of sPPB-H+ in 133 g of DMSO in a round distillation flask with stirring at 80 °C. At room temperature, a glass fiber filter into a round bottom flask was poured. A flat glass plate that had been cleaned with acidic water was used for membrane casting.

Nafion® D520 ionomer was utilized to make Nafion®-based catalyst inks. 30 wt percent Nafion® ionomer has been found as the appropriate ionomer concentration for Ketjen-black carbon substrates for these Nafion® CLs.

Fully hydrocarbon-based catalyst coated membranes (CCMs) were made by spray coating (Sono-Tek ‘Exacta-coat’) freshly prepared sPPB-H+ catalyst inks on pristine 35 μm thick sPPB-H+. The catalytic ink and the ionomer dispersion were coated sequentially onto the GDL for GDEs made by direct membrane deposition (DMD), again utilizing an automated ultrasonic spray system (Sonner Sono-Cell).

The CL shape and density were observed using an FEI Nova NanoSEM 430 scanning electron microscope.

Latest Research Findings

The top-down view of the catalyst layers reveals linked, dense layers for CLs made with Ink MeOH and Ink-EtOH, but evident fissures in CLs prepared with Ink-iPrOH. CL thicknesses made from Ink-MeOH and Ink-EtOH are identical, with anode and cathode thicknesses of 11 m and 10 m, respectively. CLs made from Ink-iPrOH have a thickness of 9 m for both the anode and cathode electrodes.

At a partial pressure of 0.98 P/P0, the total pore volume, V Total, was determined to be 0.75, 0.55, and 0.56 cm3 g1 carbon for CLs made from Ink-MeOH, Ink-EtOH, and Ink-iPrOH, respectively.

CCMs made from Ink-MeOH have the greatest fuel cell power density. The greatest power density of an individual CCM attained under atmospheric circumstances (H2/O2) for CLs made from Ink-MeOH is 1240 mW cm2, which is 8 and 118 percent larger than those prepared from Ink EtOH (1150 mW cm2) and Ink-iPrOH (569 mW cm2).

CCMs created from InkiPrOH had Rct values that were more than 80% and 72% higher than CCMs manufactured from Ink-MeOH and Ink-EtOH, respectively.

Catalyst layers produced from Ink-MeOH produce the maximum current densities for hydrocarbon sPPB-H+ based CCMs. Nonetheless, the poor ionic conductivity of CLs made with Ink-MeOH may jeopardize the current density.

Polarization curves of CCMs tuned for sPPB-H+ ionomer content utilizing Vulcan XC-72 carbon support are compared to CCMs optimized for Ketjen-black.

Future Work

Future research will focus on the effectiveness and sturdiness of fully hydrocarbon membrane electrode assemblies made from catalyst inks using low surface area carbon supports, low-boiling point dispersion media, varying ionomer content, and exertion procedures, as well as on other solvent mixtures that control the dielectric constant of the dispersant.

This would revolutionize the energy storage industry along with the electronics sector of the industry.

To summarize, the study confirmed the importance of catalyst ink composition in catalyst ink generation and its influence on the in-situ properties of fuel cells. A relationship was discovered between BET-determined surface area and pore volume and fuel cell polarization and power curves.

Furthermore, DMD has been demonstrated to be a potential path for further generation of hydrocarbon-based MEAs with even reduced ionic resistances.

References

Balogun, E., Mardle, P., Nguyen, H., Breitwieser, M., & Holdcroft, S. (2021). Catalyst layers for fluorine-free hydrocarbon PEMFCs. Electrochimica Acta. https://www.sciencedirect.com/science/article/pii/S0013468621017655

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.