.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyNov 17 2021

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyNov 17 2021A group of researchers from China and the USA synthesized a 3D conductive network of gallium-based liquid metal by adding graphene nanofillers into the matrix, to be used as a new enhanced thermal interface material in electronic circuits. This research has been published in the journal Advanced Materials Technology.

Study: Construction of 3D Conductive Network in Liquid Gallium with Enhanced Thermal and Electrical Performance. Image Credit: BeataGFX/Shutterstock.com

What are Gallium-Based Liquid Metals?

Gallium-based liquid metals (LM) are a new class of multifunctional material with excellent electrical and thermal conductivity, nonvolatility, and rheology. They have shown potential for emerging applications in robotics, 3D printing, conductors, flexible and wearable energy technologies.

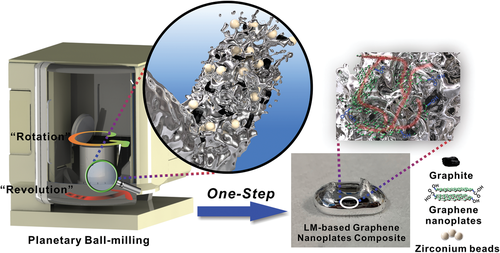

A schematic illustration that shows the preparation of the LM-GrP composite by one-step ball milling. Image Credit: Wenkui Xing et al., Advanced Materials

One of the most promising applications of LM is being used as thermal management materials. Effective thermal management is urgently needed to dissipate the large amounts of heat generated by integrated circuits chips and printed circuit boards (PCBs).

Thermal interface materials (TIMs) are commonly used to fill the air gaps between the chip and the heat sink to enhance the interfacial thermal conduction. Air is a bad conductor of heat which causes overheating of IC chips under high working loads. Comparatively, amorphous LM-based materials exhibit much higher intrinsic thermal conductivities than other conventional TIMs such as polymer-based materials.

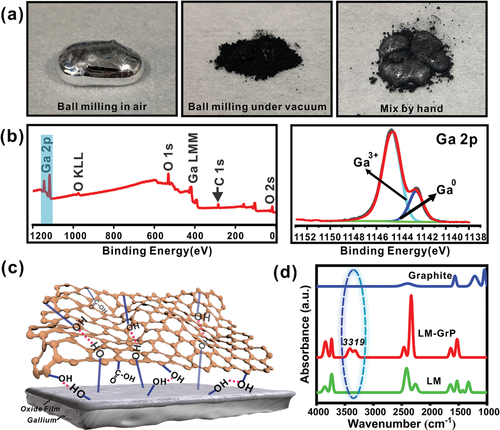

Composition analysis of the LM-based composite. a) Optical images of as-prepared LM-GrP composite, LM-graphite mixture treated under vacuum condition, and LM-graphite mixed by hand. b) XPS spectra of LM-GrP composite and Ga 2p1/2. c) Schematic illustration of hydrogen-bonding interactions of graphene with the oxide layer of LM. d) FTIR spectroscopy of graphite, LM-GrP composite, and LM. Image Credit: Wenkui Xing et al., Advanced Materials

What is the Common Problem with Liquid Metals as TIMs?

LMs in practical applications may leak out and contaminate other parts of the electronic component due to its fluidity and poor wettability. Many pieces of research have shown that slight oxidation can overcome high surface tension and low viscosity, but such oxidation reduces the intrinsic thermal conductivity of LM.

Similar to polymer-based composites, the mixing of highly thermally conductive filler into the LM matrix can improve the effective thermal conductivity.

Although metallic fillers in the LM matrix can give high thermal conductivity, most of the reported metallic particles such as Mg, Fe, and Cu would form intermetallic compounds which consume up LM and sacrifice its fluidity and become too hard to be used further. Inert and high thermal conductive particles such as nickel (Ni) and tungsten (W) would not form alloys with the LM matrix; however, this results in the emergence of microscopic geometrical features that coarsen the surface texture. 2D inorganic nanofillers such as graphene, boron nitride (BN), and graphite flakes that possess high thermal conductivity and smooth surface texture are widely used in polymer-based TIMs.

Previously polymer-based 3D interconnected filler networks have been also synthesized for the high thermal conductivity. Chemical modification, internal microstructure, and adjusting the volume mixing ratio are employed to obtain improved thermal conductivity of the generated composites.

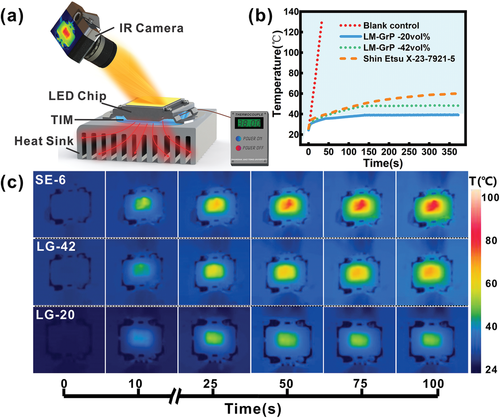

Heat dissipation test of LM-based composite. a) Schematic illustration of the experimental setup of heat dissipation in LED modules, where LM-GrP composite was used as the TIM. b) Temperature changed with time when different TIMs were used in LED modules. c) Comparison of temporal infrared images of LED modules among different TIMs. Image Credit: Wenkui Xing et al., Advanced Materials

What Does the Research Say?

The team incorporated 2D inorganic graphene nanofillers into the LM matrix to enhance the electrical, thermal, and rheological properties of the LM-based composites. Uniformly dispersing and connecting 2D inorganic nanofillers into a network in the metallic matrix is one of the critical steps to bridge fillers for improvement in heat conduction.

They preferred ball milling as the mixing process, which uses mechanical shear force and allows fast and large-scale production as well as introduces chemical functional groups to graphene nanoplates in the ball-milling cylinder when appropriate chemical liquids, solids, or vapors were used.

The researchers used a simple one-step ball-milling approach to obtain 3D thermal and electrically conductive graphene network in gallium-based liquid metal (LM). In that, 2D graphene nanofillers and their derivatives were incorporated to form 3D thermally and electrically conductive filler networks.

They found that the resulting composite shows the highest 3D thermal conductivity (44.6 W m−1 K−1) among the gallium-based LM composites with 2D inorganic nanoplates and high electrical conductivity (8.3 S.µm−1) among gallium-based liquid metal composites.

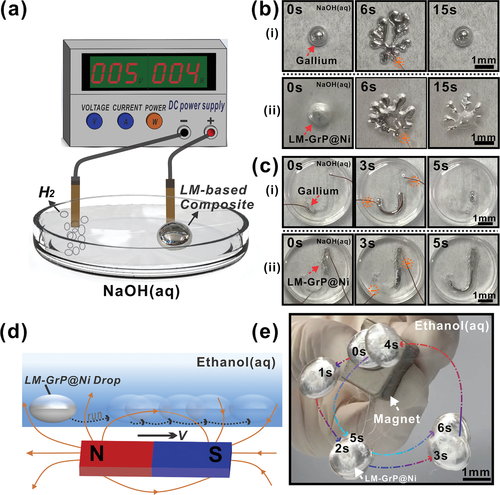

The improved thermal conductivity and wettability of gallium-based composite lead to viable usage as thermal interface materials with elegant texture for IC chip heat dissipation. The magnetic and electrochemical measurement data confirmed that these LM-based composites can also be controlled under external electrical or magnetic fields, which potentially helps extend their application in external field-driven systems.

Electrical and magnetic performances of LM-based composite. a) Schematic illustration of the experimental set-up of oxidative spreading under voltage. b) Oxidative spreading of a droplet in 1 m NaOH solution under 5 V i) pure gallium; ii) LM-GrP@Ni composite. c) The directional movement of pure gallium and LM-GrP@Ni droplets in letter-shaped “J” tracks. d) Schematic illustration of the motion of LM-GrP@Ni composite controlled by a magnet. e) The trajectory of directionally movable LM-GrP@Ni magnetic fluid guided by a magnet. Image Credit: Wenkui Xing et al., Advanced Materials

Reference:

Wenkui Xing, Shen Chen, Han Wang, Wendong Liu, Jiashu Zheng, Feiyu Zheng, Xiaomin Li, Peng Tao, Wen Shang, Benwei Fu, Jianbo Wu, Chengyi Song, Baowen Li, Tao Deng. Construction of 3D Conductive Network in Liquid Gallium with Enhanced Thermal and Electrical Performance. Adv. Mater. Technol. 2021, 2100970. https://onlinelibrary.wiley.com/doi/10.1002/admt.202100970

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.