Water pollution is an ever-present problem for modern society, and heavy metals from sectors such as industry and mining are particularly problematic due to their negative effect on ecosystems. To improve the process of removing these pollutants, a paper published in the journal Case Studies in Construction Materials has presented a novel geopolymeric foam composite coated with polylactic acid.

Study: Development of novel geopolymeric foam composites coated with polylactic acid to remove heavy metals from contaminated water. Image Credit: Creadores de Video/Shutterstock.com

Cleaning Up Heavy Metal Pollution

Pollution entering water systems is a critical issue facing modern society. Heavy metals such as lead, mercury, cadmium, aluminum, copper, and zinc can cause environmental damage and affect human health by contaminating crucial water supplies and entering the food chain. Heavy metals can leach into water systems from mining operations (even inactive ones) and heavy industrial processes and are also illegally dumped worldwide.

Traditional methods to remove heavy metal pollution include activated charcoal, zeolitic materials, and chitosan, but researchers have identified key deficiencies in these water treatment methods. Low adsorption capacity, difficulty reusing the materials, and decreased stability at both high and low pH levels have been reported. There are also issues with sustainability, eco-friendliness, and cost associated with these methods.

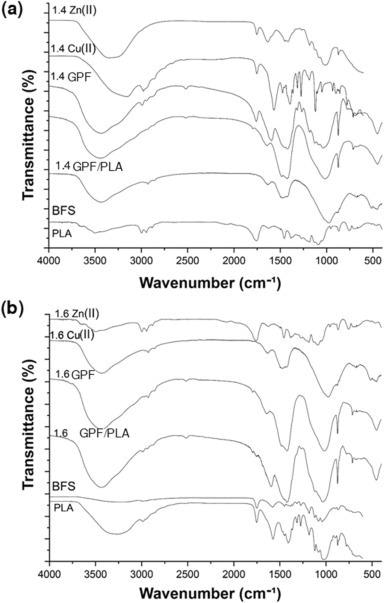

FTIR overlay spectra of neat materials (PLA and BFS) and functional groups in comparison to the GPF/PLA composite foams: (a) 1.4 g/L; and (b) 1.6 g/L. Image Credit: Ramos, F.J.H.T.V et al., Case Studies in Construction Materials

Geopolymers and Polylactic Acid

Since their discovery in 1978, geopolymers have been studied for many innovative applications in numerous industrial fields. One of the most important uses for geopolymers is as an alternative to Ordinary Portland Cement in construction. Other applications that have been investigated include metallurgy, transport applications, nuclear waste disposal, coatings, pavement construction, and soil stabilizers. They are characterized by networks or chains of inorganic molecules.

There are several properties that make geopolymers an attractive alternative material for industry, including their thermal stability, fire resistance, corrosion resistance, low density, cost-effectiveness, the versatility of processing, and the ability to manufacture geopolymers from industrial waste. Their manufacture emits significantly less carbon dioxide than Ordinary Portland Cement.

Residue-based geopolymers additionally comply with requirements that materials should be developed from the standpoint of human health and the psycho-emotional impact caused by toxic and environmentally damaging materials.

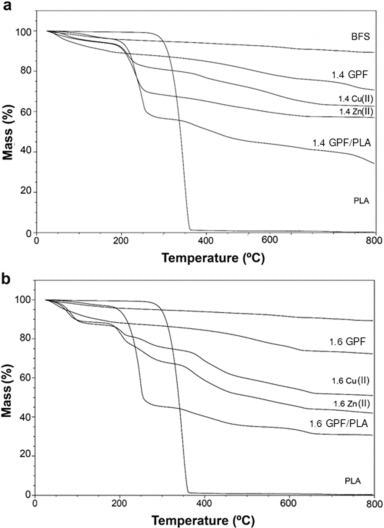

TG curves of the geopolymeric materials compared with BFS and PLA: (a) 1.4 stoichiometry, (b) 1.6 stoichiometry. Image Credit: Ramos, F.J.H.T.V et al., Case Studies in Construction Materials

Geopolymer foams have been investigated in recent years for their unique properties and applications in the industry. Polymeric fibers, which have been used to reinforce cementitious composites, have been added into geopolymers, with results of research demonstrating improved mechanical properties, crack resistance, resistance to chemical penetration, durability, and ductility improvements, and used as reinforcement fillers.

Many organic and biodegradable polymers such as ethylcellulose and polylactic acid have been investigated.

Polylactic acid (PLA) has shown many interesting mechanical, optical, and thermal properties that make them an ideal additive for composite geopolymer materials. Studies have incorporated nanoparticles into PLA to improve its mechanical, viscoelastic, thermal, and transport properties.

Additionally, surface characteristics of PLA can be modified by the inclusion of nanoparticles, improving their biocompatibility, wetness, hydrophobicity, and other properties without altering their bulk properties.

Using a Hybrid Geopolymer and PLA Composite Material for Heavy Metal Pollution Cleanup

The research presented in Case Studies in Construction demonstrated the development of a novel geopolymer/polylactic acid composite material for heavy metal pollution removal. Several types of geopolymer foam were produced from blast surface slag and coated with melted polylactic acid. Polylactic acid was used to improve the geopolymer foam’s dimensional stability and increase its ability to adsorb heavy metal ions.

The composite materials were evaluated for their ability to adsorb copper and zinc, two heavy metals that can cause environmental damage and toxicity to humans and animals due to their bioavailability. Experimental studies were encouraging.

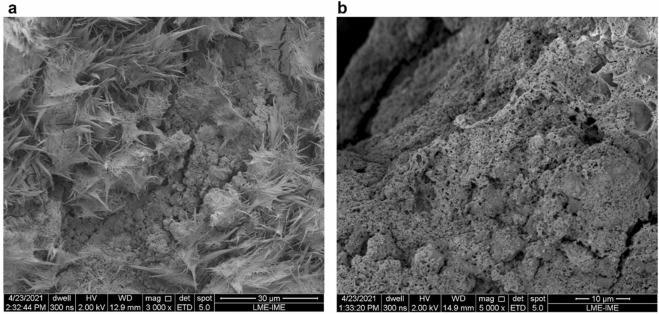

XRF studies confirmed the presence of oxide compounds in the prepared samples, demonstrating efficient synthesis. This was corroborated by FTIR analysis. XRD analysis indicated the material’s crystallographic phases along with the presence of possible minerals. Thermogravimetric studies confirmed that the samples had higher thermal stability. Scanning electron microscopy confirmed the presence of porous microstructures that facilitated the adsorption of the copper and zinc ions.

FEG-SEM images GPF/PLA foam composites: (a) 1.4 present different porous surface and polymeric fiber morphologies, as well as, (b) many small porous at a compact structure. Image Credit: Ramos, F.J.H.T.V et al., Case Studies in Construction Materials

The Future

The research published in Case Studies in Construction presented a novel hybrid composite material that can be used to remove heavy metal ions from contaminated water samples. This composite material is easily produced from industrial waste, which makes them sustainable and ecologically friendly materials. Synthesizing them reduces waste and carbon emissions.

The novel composite material displayed higher adsorption performance, thermal stability, and hard decomposition, as well as good molding processes and versatile production. Thus, the material developed in the research has several advantages over traditional materials used to treat water supplies and remove toxic and environmentally damaging heavy metal ions.

Further Reading

Ramos, F.J.H.T.V et al. (2022) Development of novel geopolymeric foam composites coated with polylactic acid to remove heavy metals from contaminated water [online] Case Studies in Construction Materials 16 (2022) | sciencedirect.com. Available at: https://www.sciencedirect.com/science/article/pii/S2214509521003107

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.