In an article recently published in the open-access journal Materials Research Express, researchers developed a composite material panel that can generate electrical energy from solar energy as a photovoltaic cell and store the energy as a structural supercapacitor.

Study: Development of solar supercapacitor by utilizing organic polymer and metal oxides for subsystem of EV, Image Credit: LuisPinaPhotography/Shutterstock.com

These panels can be used in the structural body of electric vehicles with ion-exchanging rechargeable batteries and form a hybrid energy storage system (HESS). The composite panel prototype demonstrated an additional 4.56% power generation and range per hour under a solar irradiance of 1000W/m2 for conventional electric vehicles.

Solar Supercapacitors as Body Panel in EVs

Electric vehicles (EVs) can become more efficient by incorporating several renewable energies through a cost-effective hybrid energy storage system. Among those, supercapacitors have several advantages over fuel cells and electrochemical batteries, such as higher power density, shorter charging times, and longer cycle life.

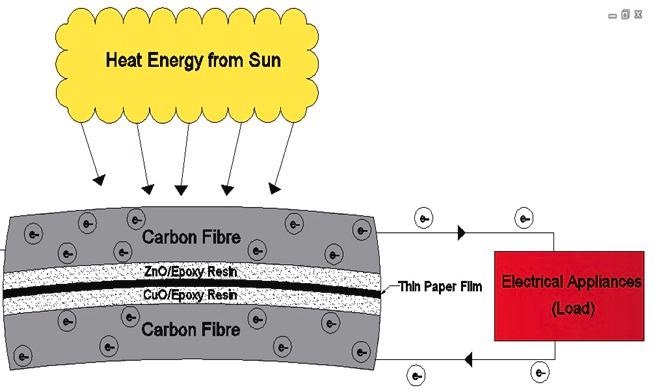

Working principle of solar supercapacitor body panel. Image Credit: Rahman, M., Aung, K., Materials Research Express

Solar energy is the closest feasible renewable energy for the automotive sector. The use of photovoltaic cells on the vehicle rooftop to harvest solar energy is not new, but if the same equipment can store that energy, it will be a gamechanger in the field of hybrid EVs. Solar supercapacitors (SSCs) are a class of capacitors that harvest and store solar energy.

Carbon materials are the most commonly used electrode materials in supercapacitors. Among those, carbon fiber (CF) proves to be the best candidate for the electric double-layer capacitor (EDLC). CF has superior charge transportation property due to one-dimensionality and high adsorption capacities to ions due to the existence of a large number of pores at the surface of the fiber.

A combination of CF, a conducting polymer such as an epoxy resin (ER), and metal oxides such as ZnO/CuO is a suitable electrode for high-performance SSCs.

About the Study

The researchers prepared several prototypes of the SSC-based composite panels with varying compositions by sandwiching thin paper film between layers of ZnO-ER and CuO-ER. The paper film was soaked in Na2SO4 electrolytes. Na2SO4 electrolyte works as a dielectric medium between CF electrodes.

Further, both ZnO-ER and CuO-ER layers are covered with two CF sheets. CF embedded n-type electrode (ZnO-CF) donates electrons in the presence of a solar energy photon, while CF embedded p-type electrode (CuO-CF) accepts electrons. Two electrodes - ZnO-CF and CuO-CF - and the electrolyte Na2SO4 form an electrical double layer supercapacitor.

The presence of CuO increases electron transfer along the surfaces of ZnO nanostructures, due to their large surface area and high catalytic activity, and also enhances the reaction process. Thus, the synthesis of both ZnO/CuO-based composite electrode materials leads to a faster charging time.

The conducting polymer ER makes the nanostructures of ZnO/CuO compact, thus storing the charge longer without discharging too fast as a conventional capacitor. Due to the presence of the conducting polymer, the panel can also harness solar energy and convert it to electricity.

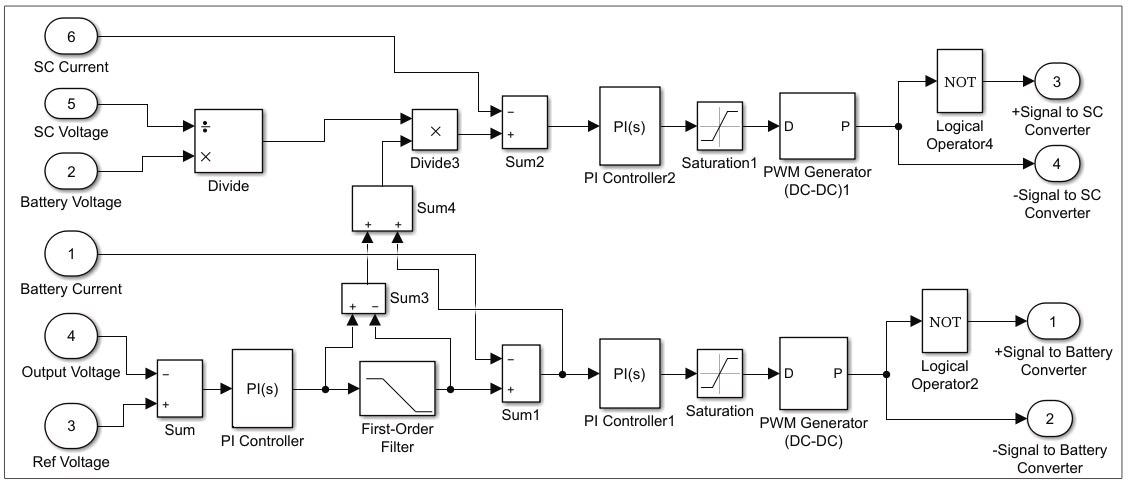

Solar Supercapacitor system in Simulink. Image Credit: Rahman, M., Aung, K., Materials Research Express

Observations

The team found that the conductivity of SSC samples improves with an increase in ZnO/CuO content. Also, samples with 20gsm paper soaked in Na2SO4 electrolyte show higher capacitance than samples with plain dielectric paper. However, CF electrodes synthesized with ordinary ER demonstrate reduced conductivity.

The efficiency of organic SSC is improved by increasing the effect of exciton generation in quantum dots, energy band gap, producing specific optical effects and enhancing the transportation and collection of electrons.

Different performance measurements of the optimized sample reveal an energy conversion efficiency of 17.78%, an open-circuit voltage of 0.79 mV, a current density of 222.22 A/m2, a capacitance of 11.17 μF/cm2, an energy density of 120 Wh/kg, and a power density of 29 kW/kg.

The fully charged SSC with solar irradiance of 1000W/m2 provides an additional 4.56% power generation and range per hour for conventional electric vehicles. The SSC has the potential to reduce EVs’(Tesla model 3) battery size by 10% and weight by 7.5% for the same power output.

PMS for solar supercapacitor in Simulink. Image Credit: Rahman, M., Aung, K., Materials Research Express

Conclusions

The researchers developed an optimized SSC prototype panel for the HEES of EVs, which can harness and store solar energy. The panel-energy-storage system has multifunctional characteristics such as weight savings, energy-storage/supply on-demand, and protection of the vehicle’s body from external heat as an insulator. The electrodes of the SSC are fabricated using materials such as CF, conducting polymer, and metal oxides such as ZnO and CuO.

The sample data indicates that the proposed HEES meets the power and energy requirements of the EV, its accessories load, and accurate power distribution between multiple storage systems. Therefore, these SSCs can improve the sustainability, cost-effectiveness, and energy efficiency of the EV sector.

Reference

Rahman, M., Aung, K., Development of solar supercapacitor by utilizing organic polymer and metal oxides for subsystem of EV, Materials Research Express, 2021, https://iopscience.iop.org/article/10.1088/2053-1591/ac3ce9

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.