Current hydrogen fuel cells have issues with durability and power density. Research published in the journal Materials has investigated how to address these challenges in fuel cell design by varying anode channel shape.

Study: Influence of Changes in the Shape of the Anode Channel in Polymer Electrolyte Fuel Cell on the Loss of Its Service Life. Image Credit: Sergii Chernov/Shutterstock.com

PEMFC Hydrogen Fuel Cells

PEMFC (Polymer electrolyte fuel cell) hydrogen cells have been in use since the 1970s when they were developed for the space program. Consisting of a proton-conducting polymer electrolyte membrane, the reaction between hydrogen and oxygen in the PEMFC cell is used to transform chemical to electrical energy.

The fuel cell’s anode and cathode are separated by the membrane, with hydrogen fed through the negatively charged anode and oxygen fed through the positively charged cathode. Protons flow across the membrane, whilst electrons flow from the anode to the cathode in the external circuit. This bypasses the membrane, and the end product of the reaction is water.

PEMFC cells have been proposed as a key technology to fill the energy gap caused by the phasing out of fossil fuels. They do not produce any downstream carbon emissions or harmful combustion emissions. Niches for the technology are in mobile and small energy applications.

Overcoming Challenges with the Technology

Although they are a promising alternative energy harvesting technology, challenges exist with PEMFC hydrogen cells. Specific problems include low power density and the durability of the membrane and the channel’s body.

Solutions to the power density issue include aerodynamic optimization of the channel. By selecting proper operating parameters and reducing flow resistance, power density generation can be improved.

The temperature in the cathode gas diffusion layer of the fuel cells influences the improvement of power density. If the temperature gradient is too low, the fuel cell start-up and durability of the membrane can be severely affected. By stabilizing the temperature gradient, performance can be improved by controlling water transport and distributing reactants faster.

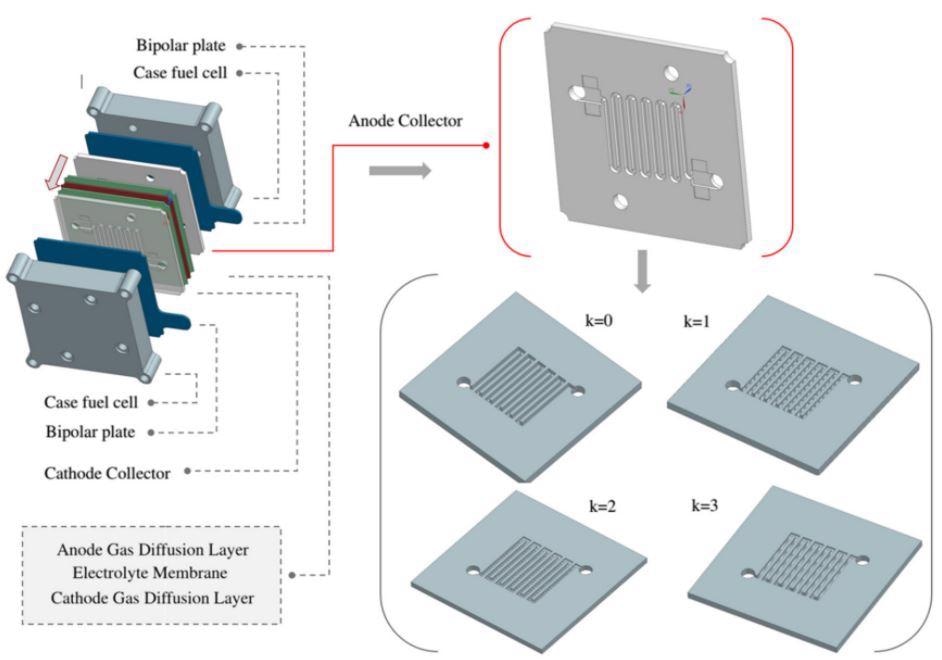

Physical model of fuel cells with proton exchange membrane. Image Credit: Sławiński, D et al., Materials

Improving water drainage from the channels can also improve power density within the cell. However, excessive pressure can cause deformation of the channels and affect the durability of the membrane, as well as causing operational tightness. Excessive strain on the materials makes constructing stacks of fuel cells difficult. All these aspects significantly influence the number of safe loads that the fuel cell can undergo.

A Novel Approach to Addressing the Challenges in PEMFC Hydrogen Cell Design

The research published in Materials used a novel approach to address the challenges in PEMFC hydrogen cell design. Wave sinusoidal fluid flow was introduced into the design. The main advantage of wave sinusoidal fluid flow is the ability to work at significantly lower flow pressures.

This directly affects the strain on materials, reducing them and improving their durability. In the research, anode channel shape was varied, and the effects of the variation were analyzed.

The sinusoidal waves of the channel’s upper surface were analyzed in several variants and compared to the results obtained for a reference cell with constant dimension channels which had a serpentine arrangement.

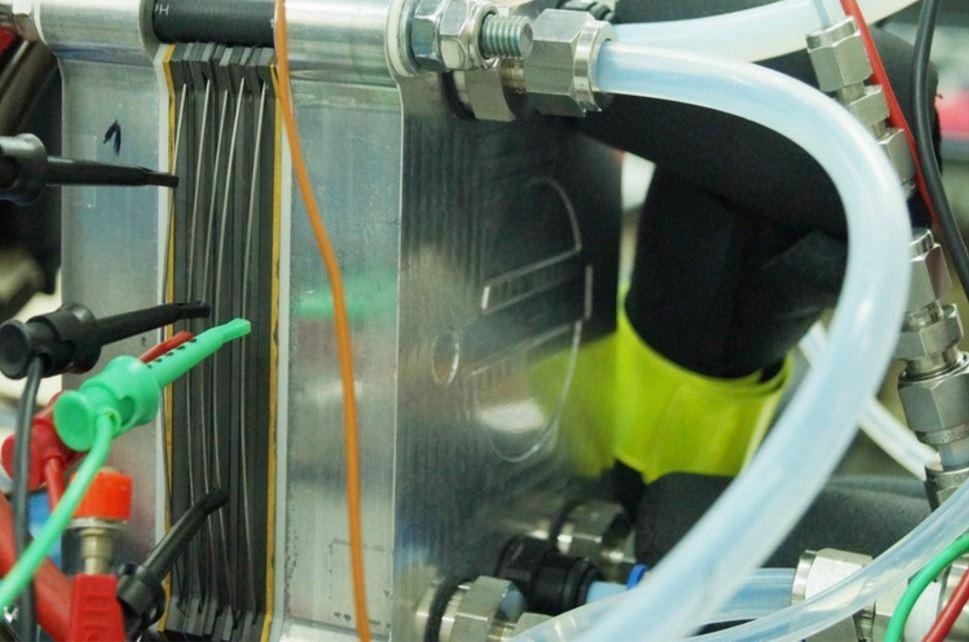

Using rigid plates and narrow channels, separators were constructed in the cell design that controlled and improved water flow and prevented flooding of active exchange areas, producing a 21% improvement in performance compared to the reference cell.

Shape changes were analyzed in the research for their influence on low-cycle fatigue and durability, as well as resistance to increases in temperature. The effect of shape changes on stress and strain fields in anode collectors was discussed in the study, as well as how changing the upper surface channel’s shape affects current-voltage characteristic curves and improves them.

According to the authors of the study, this was due to the generation of an additional convective flux.

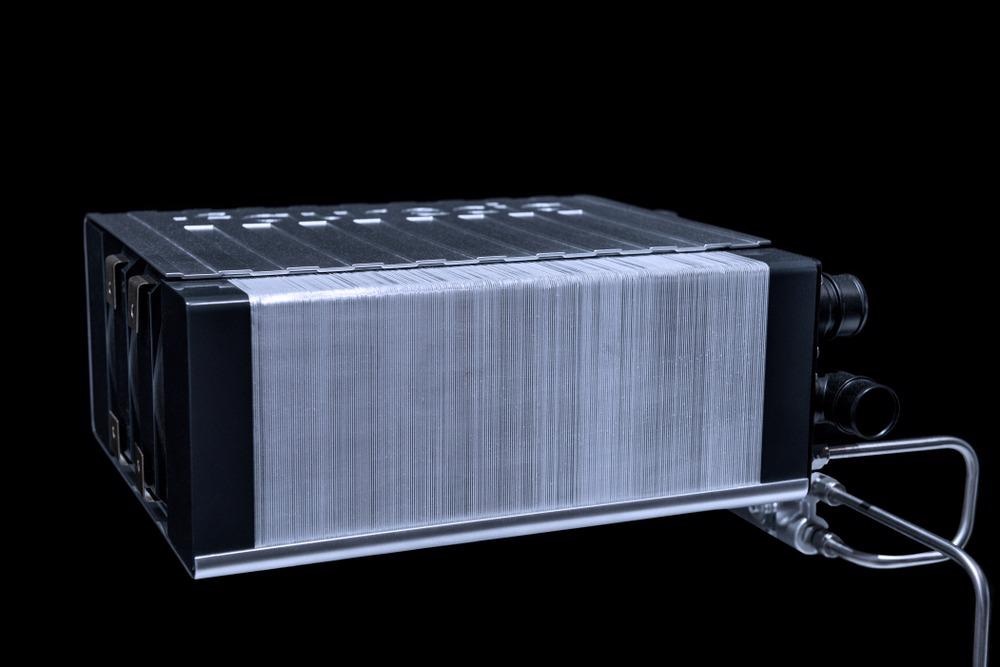

The experimental model of a PEMFC fuel cell equipped with a CSFF anode channel. Image Credit: Sławiński, D et al., Materials

By providing extra protection against high temperature, the shape changes did not significantly change the fuel cell’s safe operation time. This provided advantages for the safe operation and lifetime of the PEMFC cells. The number of cycles before destruction was not significantly affected by the design. Reducing flow resistance and selecting the proper operating parameters improved the density of power generation from 4.7% to 7%.

The Future

The research presented in Materials has investigated how varying the anode collector shapes in PEMFC hydrogen fuel cells can improve their performance, durability, and lifespan. This research will help to inform the future direction of hydrogen fuel cell design.

Moreover, the technology’s uptake in the energy sector will be improved by providing more reliable fuel cells that will help reduce carbon emissions and bridge the energy gap caused by moving away from fossil fuels.

Further Reading

Sławiński, D et al. (2021) Influence of Changes in the Shape of the Anode Channel in Polymer Electrolyte Fuel Cell on the Loss of Its Service Life [online] Materials 14:23 | mdpi.com. Available at: https://www.mdpi.com/1996-1944/14/23/7338

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.