Flat materials that can transform into three-dimensional shapes might be used in medicine, architecture, space travel, robotics and various other fields. However, programming these shape changes demands longer and sophisticated calculations.

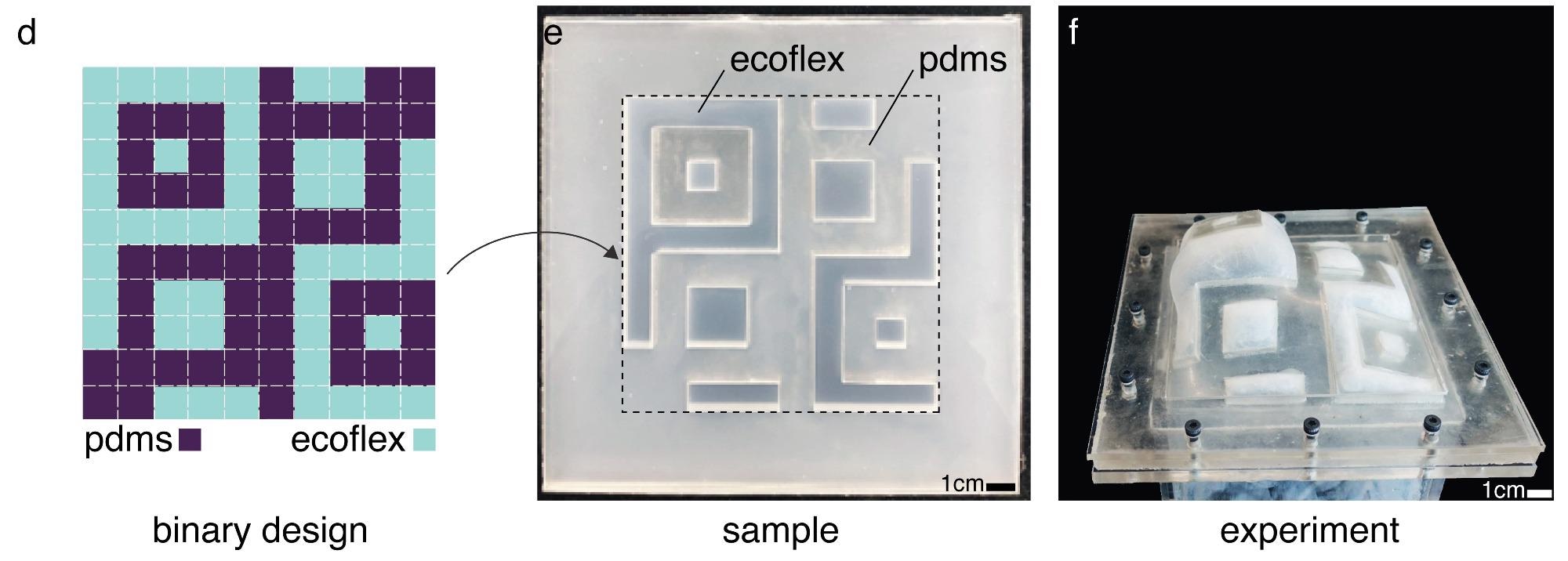

The researchers used a regular grid (left) to divide the membrane’s domain into pixels, which could be soft (blue) or stiff (purple). The membrane (center) can be fabricated as a continuous, flat material but upon inflation (right), the bi-material membrane assumes complex deformation, depending on the position of stiff and soft pixels. Image Credit: Bertoldi Lab/Harvard John A. Paulson School of Engineering and Applied Sciences.

The researchers used a regular grid (left) to divide the membrane’s domain into pixels, which could be soft (blue) or stiff (purple). The membrane (center) can be fabricated as a continuous, flat material but upon inflation (right), the bi-material membrane assumes complex deformation, depending on the position of stiff and soft pixels. Image Credit: Bertoldi Lab/Harvard John A. Paulson School of Engineering and Applied Sciences.

Currently, scientists from Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) have created a platform that employs machine learning to program the transformation of 2D stretchy surfaces into certain 3D designs.

While machine learning methods have been classically employed for image recognition and language processing, they have also recently emerged as powerful tools to solve mechanics problems. In this work we demonstrate that these tools can be extended to study the mechanics of transformable, inflatable systems.

Katia Bertoldi, Study Senior Author, William and Ami Kuan Danoff Professor, Applied Mechanics, Harvard John A. Paulson School of Engineering and Applied Sciences

The study has been published in the journal Advanced Functional Materials.

The researchers started the process by splitting an inflated membrane into a 10 × 10 grid of 100 square pixels that may be rigid or soft. Manual programming is particularly challenging since the soft or stiff pixels may be integrated into an almost limitless number of combinations. That is where machine learning comes into play.

To sample this infinite design space, the researchers employed finite element simulations. The position of soft and stiff pixels governs the deformation of the membrane when it is pressurized, according to neural networks.

Once the machine learning model was trained, we came up with an arbitrary 3D shape and passed it to the model. The neural network then outputs the membrane design and the pressure at which we should inflate such membrane to obtain the desired 3D shape.

Antonio Elia Forte, Study First Author and Former Postdoctoral Fellow, Harvard John A. Paulson School of Engineering and Applied Sciences

The researchers applied this innovative design strategy to develop and test a mechanotherapy device that stimulates tissue surrounding a scar to improve healing and speed up recovery.

Forte stated, “This platform has potential to quickly and effectively design patient-specific devices for mechanotherapy and beyond. Before this research, we didn’t know how to use machine learning to unravel nonlinear mappings in inflatable systems but it turns out that they are very powerful for these purposes.”

The platform may be used to develop morphable surfaces at various scales for a variety of applications, ranging from medical devices to architecture.

According to Forte, this is only the start of the machine-learning-assisted material design of transformable materials.

Machine learning could push the boundaries of currently known design strategies and allow us to design and build fully reconfigurable shape-morphing material.

Antonio Elia Forte, Study First Author and Former Postdoctoral Fellow, Harvard John A. Paulson School of Engineering and Applied Sciences

The study was co-authored by P. Z. Hanakata, L. Jin, E. Zari, A. Zareei, M. C. Fernandes, L. Sumner and J. Alvarez. The research was financially supported in part by the National Science Foundation through grants DMR-2011754, DMREF-1922321, OAC-2118201 and DMR-1608501.

Journal Reference:

Forte, A. E., et al. (2022) Inverse Design of Inflatable Soft Membranes Through Machine Learning. Advanced Functional Materials. doi.org/10.1002/adfm.202111610.