.jpg) By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 27 2022

By Susha Cheriyedath, M.Sc.Reviewed by Skyla BailyJan 27 2022A team of researchers recently published a paper in the journal Materials that demonstrated the correlations between poly ether ether ketone (PEEK) printing behaviors and nozzle temperatures in the fuse filament fabrication three-dimensional (FFF 3D) printing process.

Study: 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Image Credit: Oleksiy Mark/Shutterstock.com

Background

PEEK, one of the crucial replacement materials for high-performance metals, is primarily a semi-crystalline resin with high thermal stability, mechanical strength, and chemical resistance. The melting temperatures (Tm) and the glass transition temperature (Tg) of PEEK are 343 and 143 oC, respectively, which satisfy the thermal stability needed for end-use applications such as aerospace, military engineering, energy storage, and medical implants.

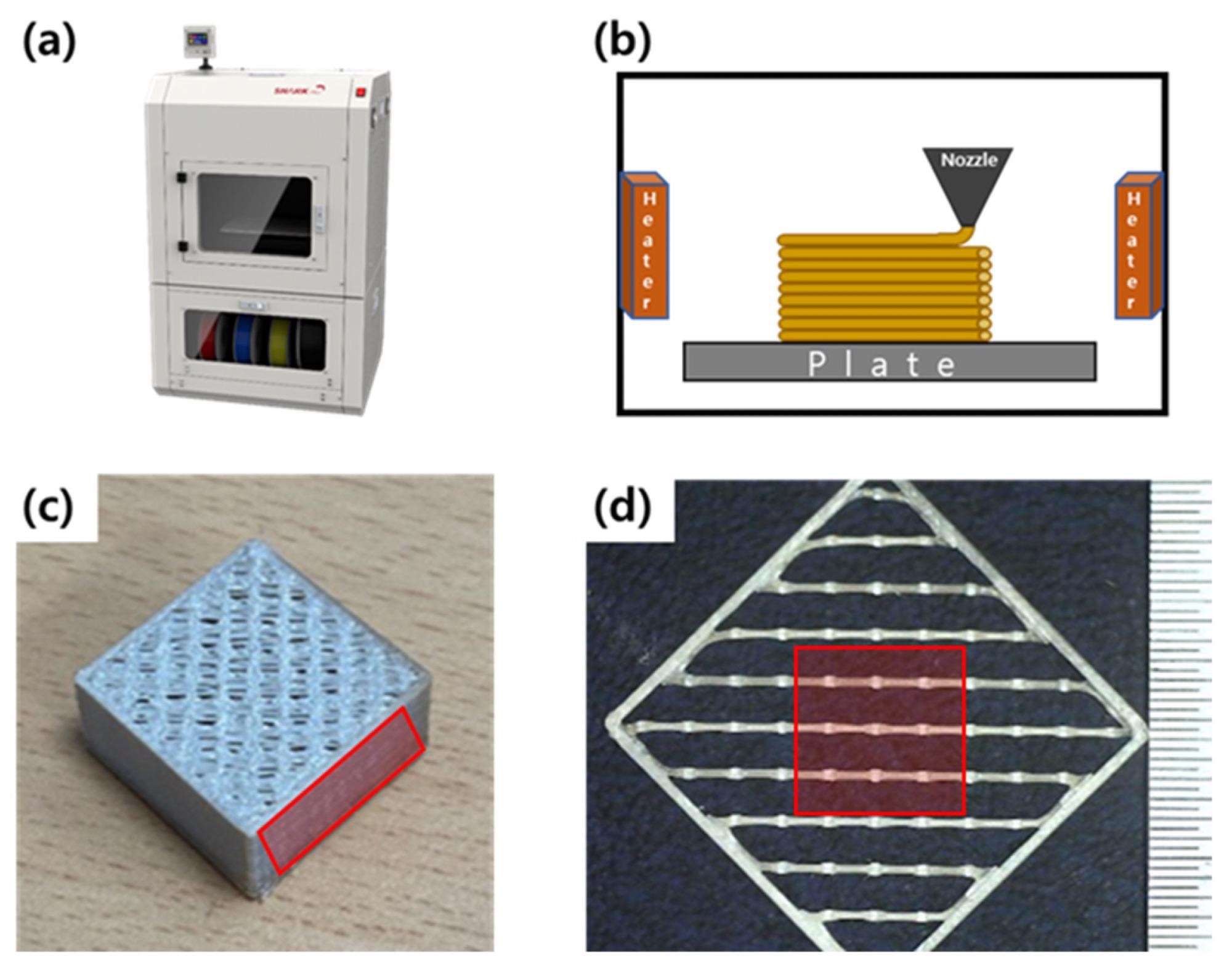

Specimens for measurement line width: (a) fused filament fabrication (FFF) system, (b) scheme of 3D printing process, (c) 3D Printed PEEK, and (d) mono-layer between PEEK printed lines. Image Credit: Baek, I. et al., Materials

A step-growth polymerization reaction is employed to produce the material. Additive manufacturing (AM) is used to fabricate the PEEK-based 3D objects in order to use them in different applications. AM technology utilizes computer-aided design (CAD) systems with simulation capabilities to fabricate 3D objects, which increase the fabrication speed and reduce the fabrication cost and time. This fabrication method can be segmented into seven categories based on the processes and materials used in the method.

Among these categories, selective laser sintering (SLS) is used extensively in heavy industries such as medical devices and automotive design owing to simpler post-processes than other printing methods and its ability to print different powder materials. However, PEEK materials experienced deformation or distortion in SLS printing owing to the higher shrinkage rate of PEEK materials compared to other plastics.

FFF is another method used to fabricate the PEEK materials. This method offered an economic advantage as the method only involved AM, heating, and melting of filaments. However, the FFF printing leads to crystallization and shrinkage of the PEEK material, which affects the strength and surface roughness of the material, leading to fatigue failure and cracks.

Heat treatment can be used to substantially decrease the shrinkage rates and improve the bonding strength and precision of the PEEK. However, research on the ways to interconnect the PEEK printing behavior to printing parameters has been sparse. In this study, researchers investigated the correlations between PEEK printing behaviors such as the reliability of printed line widths and surface roughness and nozzle temperatures.

The Study

An FFF 3D printer where the nozzle temperature can be augmented up to 400 oC was used to print the PEEK. The chamber temperature, Tg, and Tm during printing were fixed at 110, 143, and 334 oC respectively. The PEEK filament was dried at 100 oC for 5 h in order to prevent any absorption of water. The dried PEEK was extruded through the heating nozzle, and then laminated above a metal plate using a lamp.

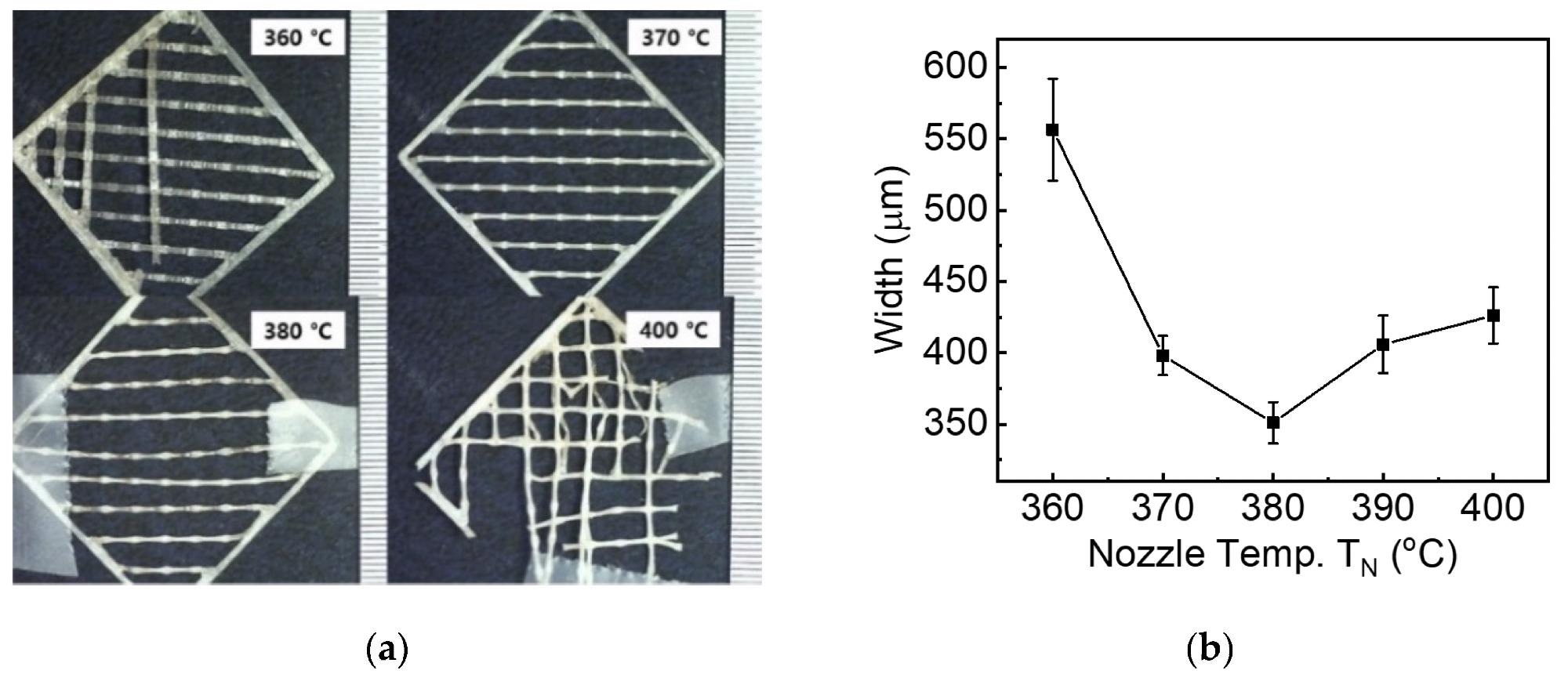

Width of PEEK lines printed at the different nozzle temperatures (TN). (a) Optical images showing the width of the printed lines contacted in consequential layers; (b) Line width as a function of nozzle temperature printed at the fixed chamber temperature of 100 °C. Image Credit: Baek, I. et al., Materials

Different nozzle temperatures of 400, 380, 370, and 360 oC were used to prepare the samples. The layer thickness was kept at 200 μm, while the printing speed was set at 15mm/s. The Ultimaker Cura software program was utilized to slice the sample into 200 × 200 × 100 mm3 pieces with a wall thickness of 400 μm and an infill percentage of 60%. The monolayer between 290th and 300th layer was separated, and the contact area width was calculated to check the impact of every test on the contact area width of the printed lines.

The surface roughness of PEEK samples was measured using a stylus profilometer. The movement speed and the radius of the stylus were 1 mm/s and 25μm, respectively. 3D mapping and line drawing were used to investigate the surface roughness of the side samples of FFF samples, while Weibull modulus was employed to determine the width of printed lines in various nozzle temperatures.

Observations

The FFF object dimensions were directly impacted by the layer thickness, printing speed, chamber temperature, and nozzle temperature. The PEEK filaments that were printed at higher temperatures become more viscous and wider, indicating instability in the fabrication of PEEK-based 3D objects. The width of the printed lines was 550 μm when the nozzle temperature was 360 oC, and 1.7 mm PEEK filaments were printed out of the FFF nozzle.

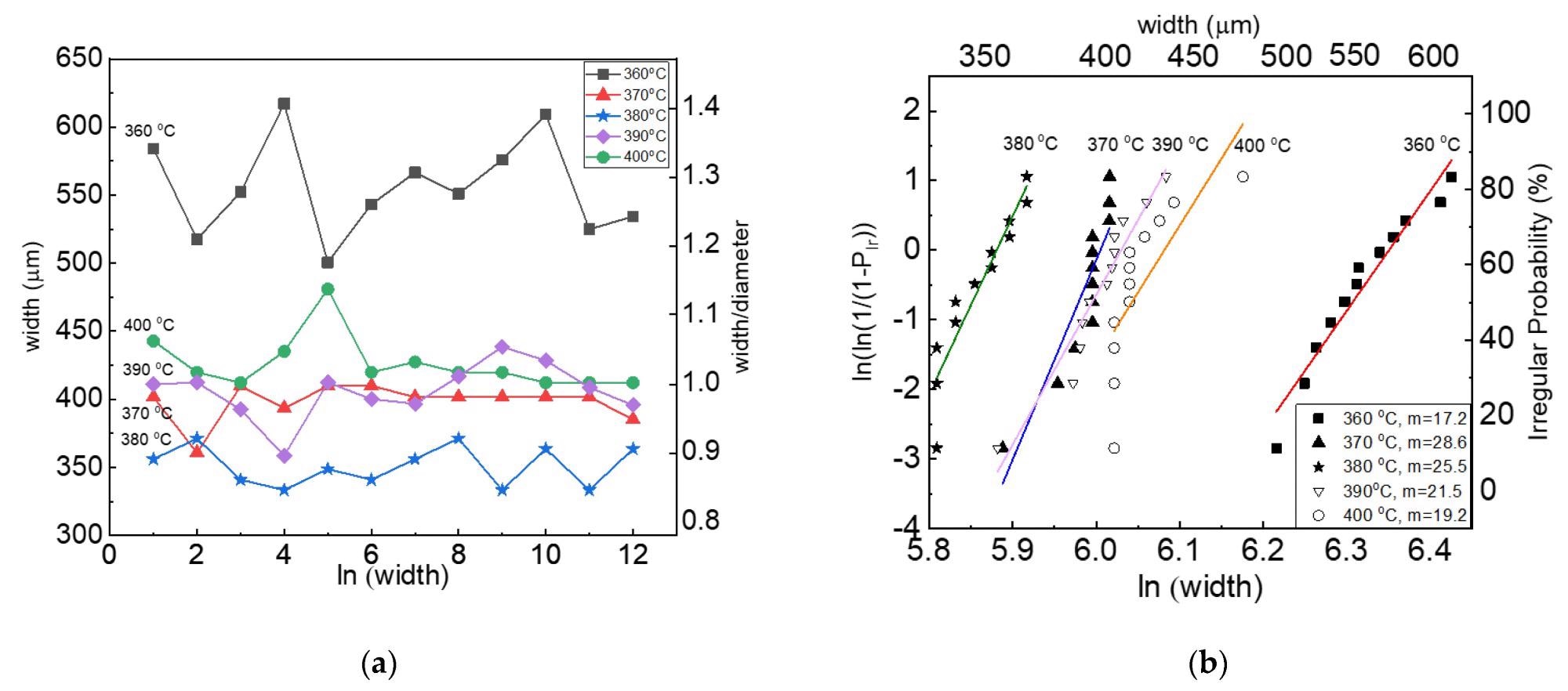

Analysis of printed line reliability used by Weibull modulus: (a) Measurement value ratio of line width and nozzle diameter, (b) Weibull plot of the line width with various nozzle temperatures. Image Credit: Baek, I. et al., Materials

The printed line width was reduced from 550 to 350 μm when the nozzle temperature was increased from 360 to 380 oC. However, the PEEK filaments experienced a phase transition from solid to liquid and printed out disconnected and distorted lines when the nozzle temperature was increased to 400 oC. The surface roughness of PEEK objects initially reduced from 56 to 49 μm and then increased to 55 μm when the temperature rose from 360 to 400 oC.

The PEEK was melted down and solidified quickly during its passage through the printing nozzle at the printing temperature of 400 oC, resulting in rough surfaces of 55 μm, which is larger than the surfaces created at printing temperature of 380 oC. The width of the printed line was most uniform at 380 oC, and the value of the Weibull coefficient of this line was also the highest at 28.6.

This study evaluated the correlation between PEEK printing behaviors and nozzle temperatures. Future research must focus on the tensile strength of PEEK to evaluate the correlation between mechanical characteristics and nozzle temperature.

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Source:

Baek, I., Kwon, O., Lim, C.-M. et al. 3D PEEK Objects Fabricated by Fused Filament Fabrication (FFF). Materials 2022, 15, 898. https://www.mdpi.com/1996-1944/15/3/898/htm